Anti-pulp-throwing edge trimming wheel mechanism for hand towel production equipment and use thereof

A technology for production equipment and paper towel, applied in paper machine, wet end of paper machine, paper making, etc., can solve the problem of serious pulping, and achieve the goal of reducing energy consumption, reducing power consumption of broken paper, and saving energy consumption for drying. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

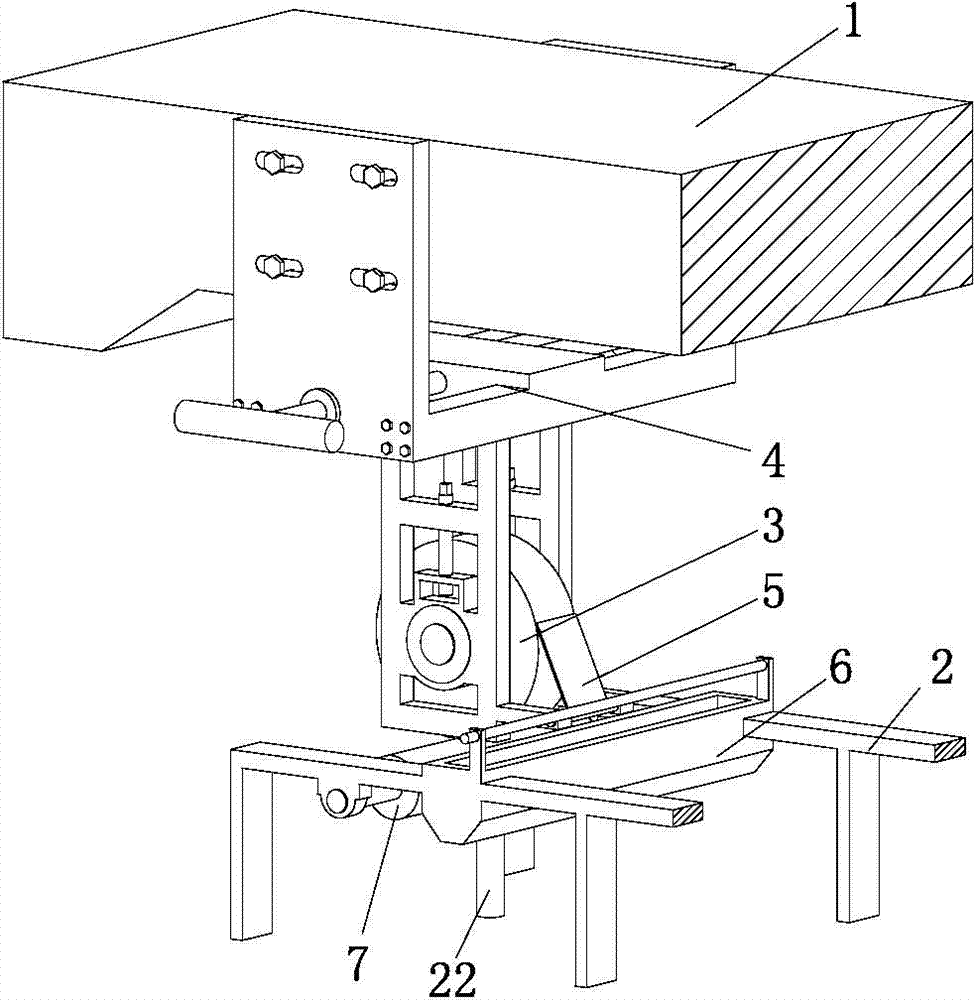

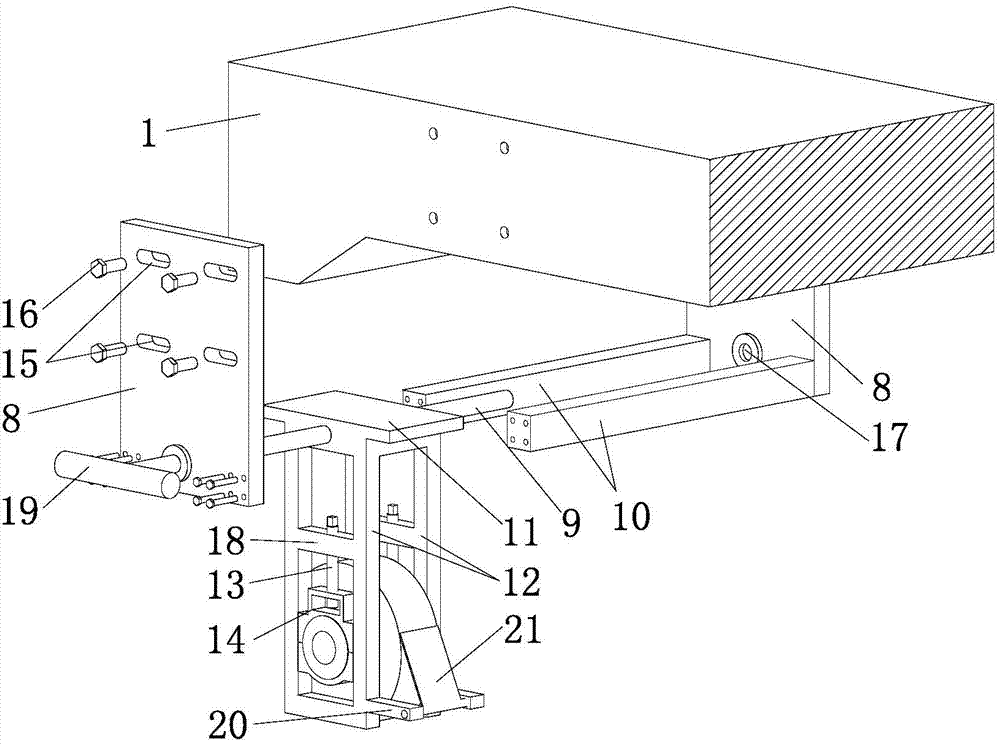

[0026] Such as figure 1 As shown, an anti-flapping pulp edge-receiving wheel mechanism for paper towel production equipment includes an upper frame 1, a lower frame 2, and an edge-receiving wheel 3. The edge-receiving wheel 3 is installed on the upper machine through a multi-directional adjustment mechanism 4. On the frame 1, a squeegee mechanism 5 is installed on the multi-directional adjustment mechanism 4, and the lower frame 2 is provided with a slurry recovery tank 6 and a support roller 7, the slurry recovery tank 6 is located directly below the squeegee mechanism 5, and the support roller 7 Be located at the bottom of edge finishing wheel 3 and be connected with it by rolling. The slurry recovery tank 6 is a bucket-shaped structure, the bottom of the slurry recovery tank 6 is provided with a slurry recovery pipe 22, the surface of the edge finishing wheel 3 is a smooth surface with a surface roughness Ra≤100 μm, and the surface of the idler roller 7 is provided with a m...

Embodiment 2

[0033]The purpose of an anti-swing pulp edge-receiving wheel mechanism for paper towel production equipment is to use it for the papermaking of low-quantity paper types, and the speed of the paper machine is ≤500m / min. The part is used to avoid the loss caused by the trimming of the paper processing machine, and it does not need to be glued when used in the wire part, which improves the service life of the trimming wheel.

[0034] Its specific working process in the paper machine is as follows: the spraying width of the headbox of the paper machine is 3000mm, and it passes through the forming part, chopping board or vacuum suction box dehydration element, and reaches the anti-swing pulp receiving wheel mechanism. The edge finishing wheel can accurately shape the wet paper page to a certain value between 2800mm and 2950mm according to the paper processing machine or customer demand, and the excess wet paper edge will be taken away with the edge finishing wheel. The edge finishi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface finish | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com