Hydraulic fracturing crossing hole pitchup hole sealing method of broken surrounding rock

A technology of hydraulic fracturing and drilling through layers, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., to achieve the effect of wide practical range, wide pressure resistance range and good hole sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for sealing upward holes in hydraulic fracturing drilling holes in broken surrounding rocks, comprising the following steps:

[0022] 1) Drilling: In the fracturing drilling site, use a fully hydraulic drilling rig and a drill bit with a diameter of 118mm to drill. Adjust the drilling depth according to the spatial relationship of the fracturing drilling site, which should be greater than 5 times the width of the space along the drilling direction).

[0023] 2) Casing: In the large hole, a plastic casing with an outer diameter of 108mm is introduced, and a 5m-long plastic return pipe with an outer diameter of 8mm is introduced between the casing wall and the borehole wall. The gap between the casing wall, the borehole wall and the air return pipe is simply fixed with polyurethane, and then the air return pipe is used to inject cement slurry for sealing, and the sealing length is less than 5m.

[0024] 3) High-pressure grouting: Use a grouting pump to inject ce...

Embodiment 2

[0030] 1. Experiment location: According to the development and production design of Linhuan Coal Mine and the gas control plan, it is preliminarily determined that the roof hydraulic fracturing experiment will be carried out in the 9th coal seam floor rock roadway of Linhuan Coal Mine-9134 machine roadway floor pumping and drainage roadway. Three fracturing points of 3#, 4# and 5# are arranged, which are respectively located at 13#, 15#, and 17# drilling sites of the floor pumping and drainage lanes of 9134 machine roadway, and the fracturing sequence is 3#→4#→5#.

[0031] 2. Drilling design:

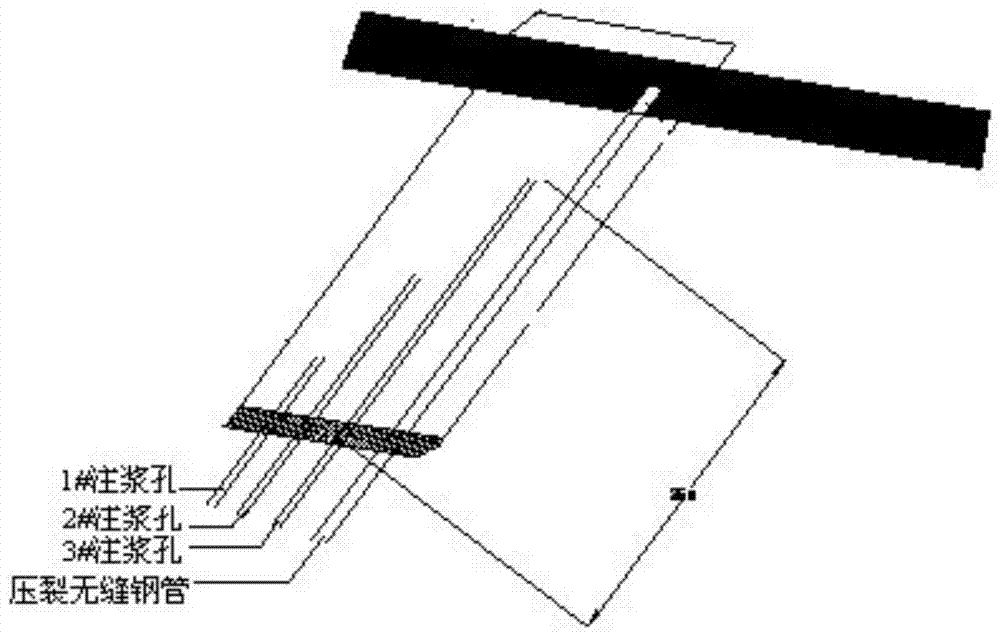

[0032] In each fracturing drilling site, a fracturing hole is constructed perpendicular to the center line of the floor pumping and drainage roadway of 9134 machine roadway and facing the direction of the 9th coal seam.

[0033] 3#, 4#, 5# fracturing point fracturing drilling final hole reaches 0.5m of the roof of the 9th coal seam, adjust the design drilling inclination, so that the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com