Flexible bearing, application and assembly method based on full-ball design

A technology of flexible bearings and assembly methods, which is applied in the direction of flexible bearings, rotating bearings, bearings, etc., can solve the problems of retainer damage and increase complexity, and achieve the effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

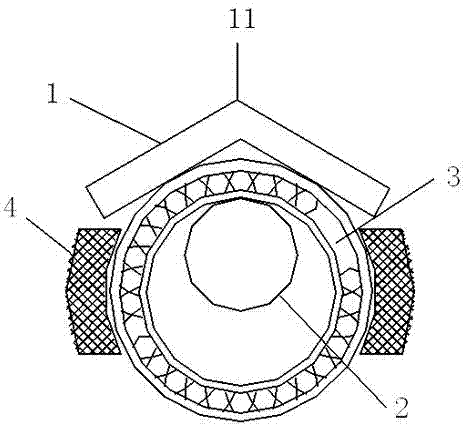

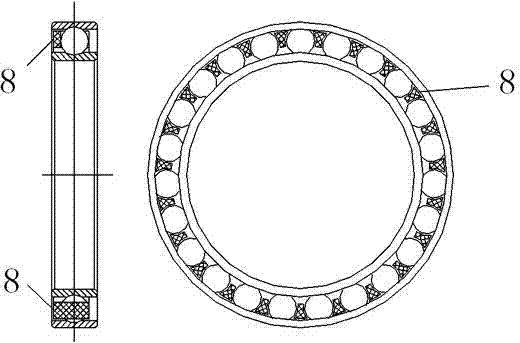

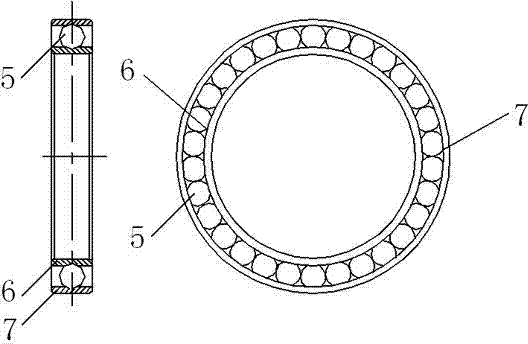

[0040] Such as figure 1 As shown, a flexible bearing assembly method based on a full-ball design, while heating the inner and outer rings of a non-full-ball flexible bearing of a common design, put the flexible bearing horizontally into the upper part to form a "person" that can move up and down. ” font 1, the lower part is in the middle of a fixed cylindrical 2 mold, and an electromagnetic heating device 4 is arranged around the mold 2. The outside of the upper end of the outer ring is close to the lower end of the "herringbone"-shaped mold 1, and the inner side of the upper end of the inner ring is close to the upper end of the cylindrical mold 2. Continue to squeeze the "herringbone"-shaped mold 11 vertically from top to bottom, so that the The flexible bearing produces elastic deformation. At this time, the inner and outer rings at the left and right upper ends of the flexible bearing are opened, and steel balls are filled in here until they are full, completing the assemb...

Embodiment 2

[0044] Compared with Example 1 in Example 2, the N is 27-30.

[0045] The utility model relates to a flexible bearing based on a full-ball design, and the bearing is applied to a flexible bearing cam type wave generator of a harmonic reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com