Hole diameter measuring method based on staggered combination of laser trigonometry displacement sensors

A technology of displacement sensor and laser triangulation, which is applied in the direction of measuring devices, instruments, optical devices, etc., to achieve the effect of increasing the measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An aperture measurement method based on laser triangulation and dislocation combination of displacement sensors of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

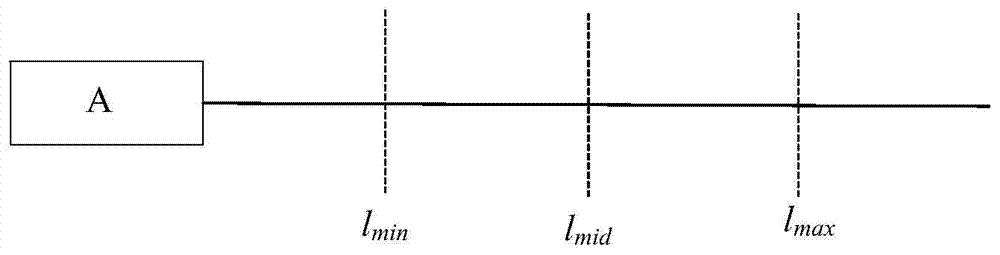

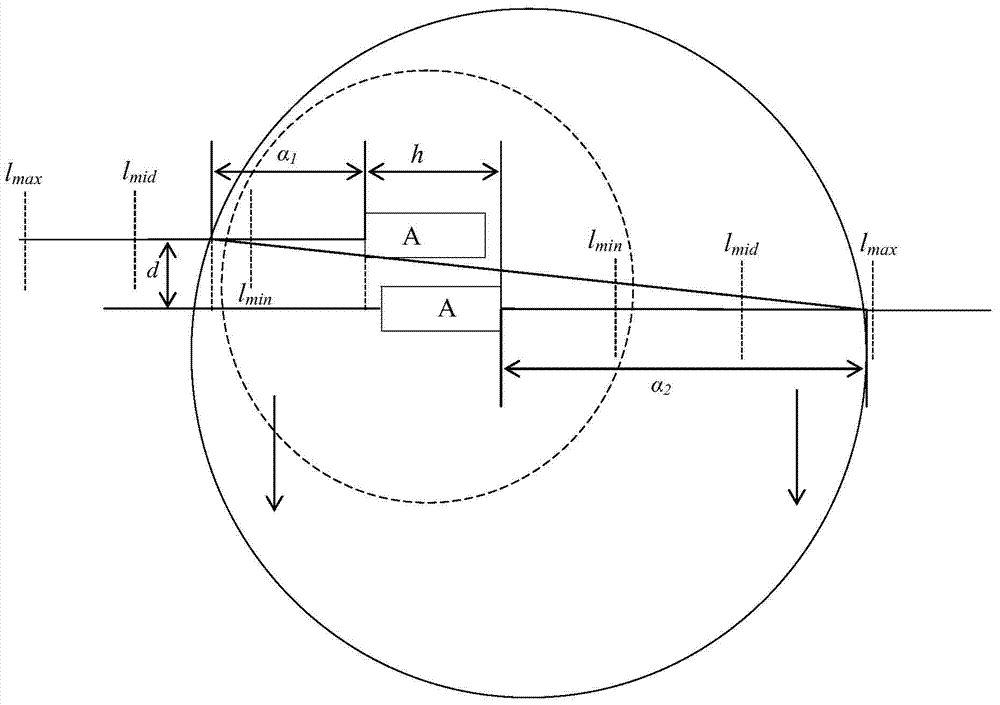

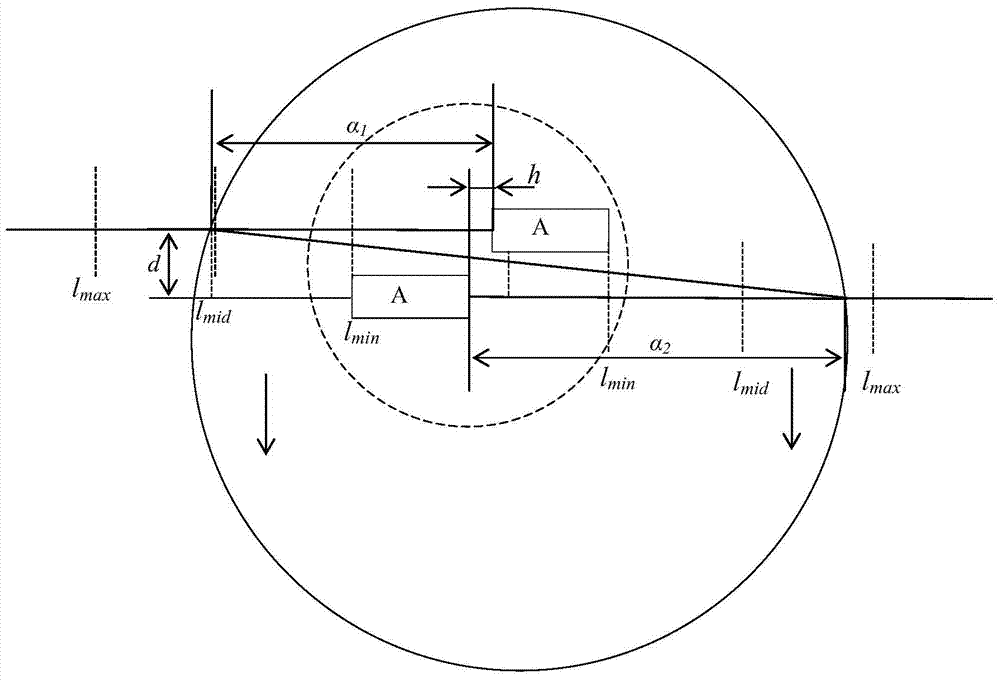

[0020] Such as figure 1 As shown, what we see is a schematic diagram of the working range of the laser triangulation displacement sensor. Each laser triangulation displacement sensor has its own working distance, that is, the working center distance l mid and scope of work. These two parameters are important parameters of the laser triangulation displacement sensor, which restrict the hole measurement capability of the entire laser displacement sensor hole measurement system. Wherein, the working range mentioned is the farthest working distance l max The closest distance to work l min the distance between.

[0021] A method for measuring aperture based on laser triangulation displacement sensor dislocation combination of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com