An energy isolation system and energy isolation method for an oilfield combined station

An isolation system and combined station technology, applied in the field of electromechanical device safety equipment, can solve the problems of frequent production accidents, accidental release of energy, hidden safety hazards, etc., and achieve the effects of avoiding equipment damage, controlling accidental release, and controlling risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

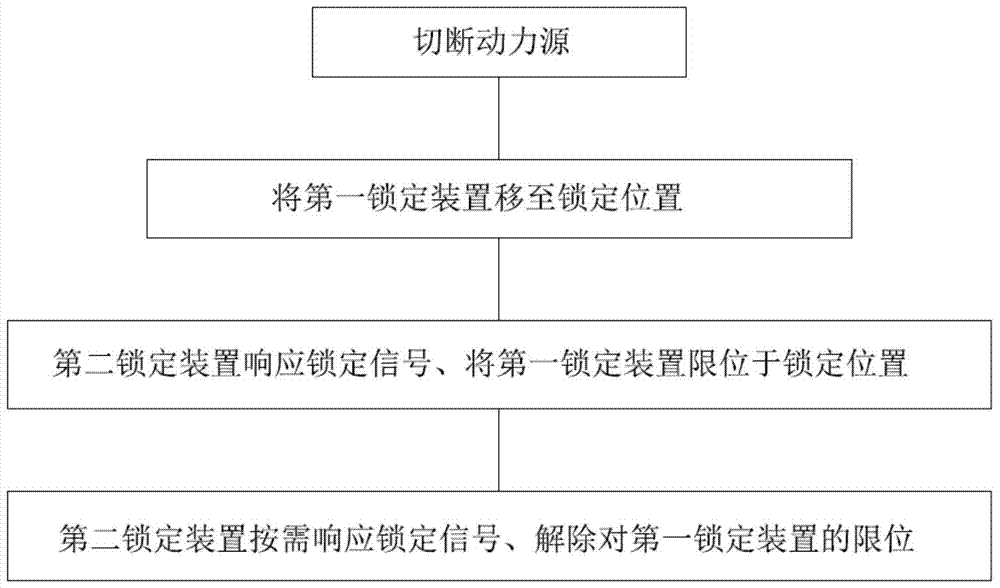

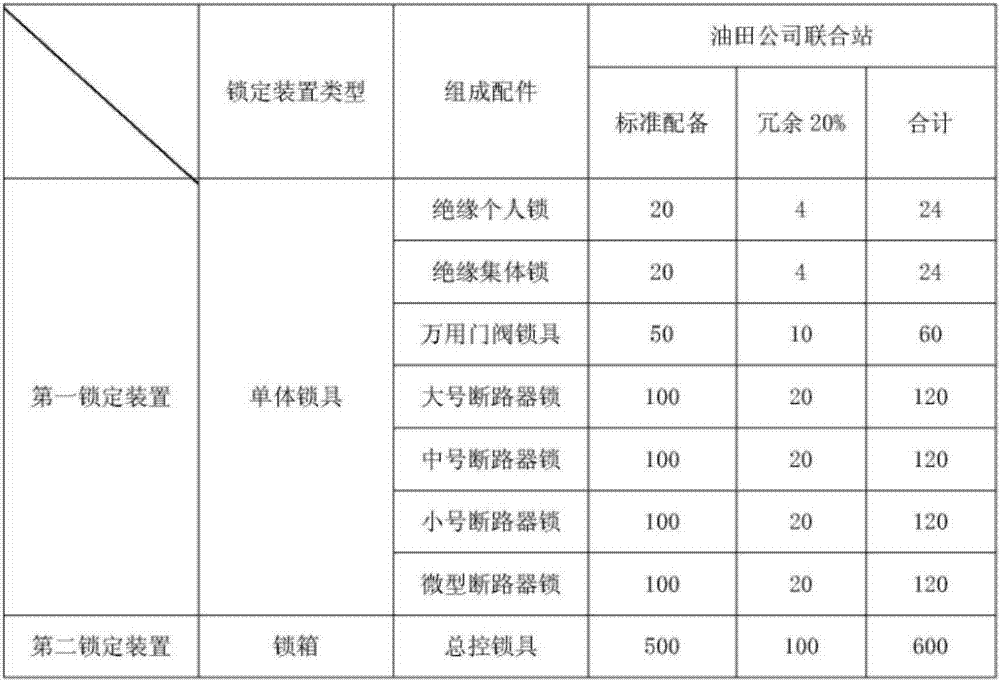

[0030] The main purpose of this embodiment is to provide an energy isolation system applicable to the oilfield field, during installation, maintenance, service and repair activities, to protect workers from accidental release of hazardous energy. The energy isolation system and energy isolation method of the oilfield combined station where personnel misoperation causes safety accidents.

[0031] The energy isolation in this embodiment refers to using the energy isolation system to isolate and lock the closed energy according to a certain procedure, so as to ensure that the relevant personnel working on the equipment or devices are not harmed.

[0032] Specifically, the energy isolation system of the oil field joint station includes an energy isolation device and an electromechanical device to be isolated. The energy isolation device is provided with a first locking device, and the first locking device can move between a locked position and an unlocked position. - when the lock...

Embodiment 2

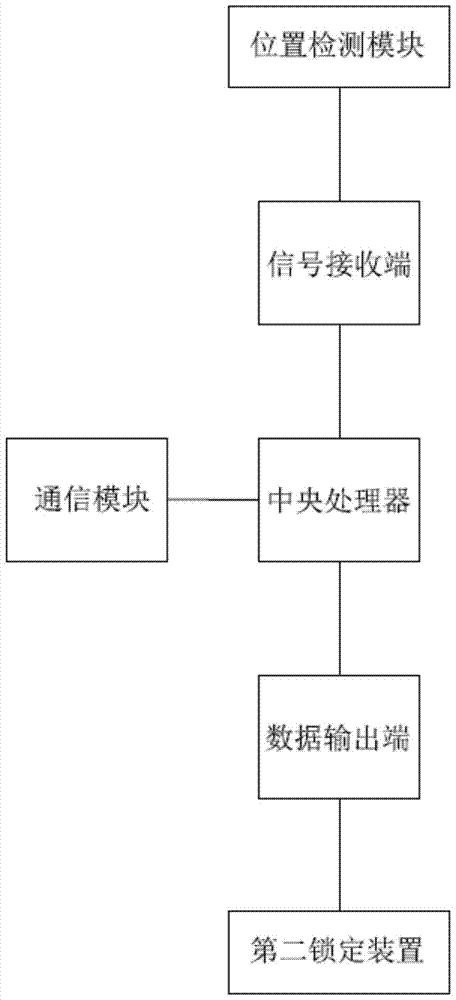

[0050] The main purpose of this embodiment is to provide an energy isolation system applicable to the oilfield field, which implements energy isolation by means of information technology, and then effectively avoids the accidental release of dangerous energy, so as to prevent or reduce safety accidents caused by misoperation of staff The energy isolation system and energy isolation method of the oilfield combined station.

[0051] The difference between this embodiment and Embodiment 1 mainly lies in the movement structure and control structure for locking or unlocking the first locking device

[0052] The energy isolation system of the oilfield combined station in this embodiment mainly includes a central processor, the second locking device is controlled by the central processor, and the central processor is connected with a position detection module for detecting whether the first locking device is in the locked position or the unlocked position, The central processor is pr...

Embodiment 3

[0065] The difference between this embodiment and Embodiment 1 mainly lies in the unlocking structure and unlocking method of the second locking device.

[0066] The main purpose of this embodiment is also to provide an energy isolation system applicable to the oilfield field, which implements energy isolation by means of information technology, and thus effectively avoids the accidental release of dangerous energy, and prevents or reduces safety accidents caused by misoperation by operators. The energy isolation system and energy isolation method of the oil field joint station, and further, provide a more flexible management method, avoiding the energy isolation system and energy isolation method of the oil field joint station that cannot be unlocked because the supervisor is not on site and affects the construction period ,details as follows:

[0067]The central processing unit in this embodiment is provided with a communication module, and the communication module is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com