Novel high-current reed-type switch contact structure

一种开关触点、簧片式的技术,应用在新型大电流簧片式开关触点结构领域,能够解决电触点烧毁、无法承载电荷负载、没办法加入灭弧装置等问题,达到增大电荷承载能力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

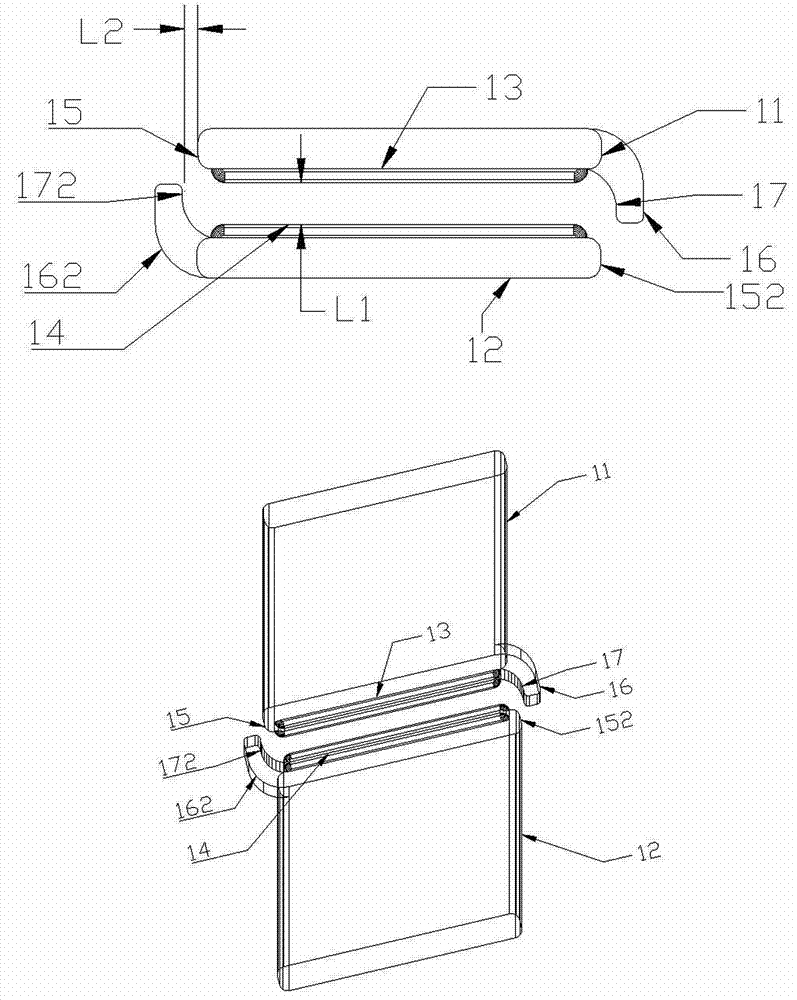

[0016] Example 1: figure 1 Shown is a new type of high-current reed switch contact structure, which is a schematic diagram of the reed switch normally open state. It consists of at least one set of elastic reed electrodes (11, 12) or at least one fixed electrode (12) and one elastic reed electrode (11); the electrodes (11, 12) are made of conductive materials, One of the end faces overlaps with each other, and there are contacts (13, 14) on the opposite surface of the overlapped ends. The reed electrode (11,) has a protruding arc discharge device (16) on the side of the contact end, and the reed electrode (12) ) There is a protruding arc discharge device (162) on the side of the contact end; there is a certain gap between the reed electrode contacts (13, 14); the frontal distance (L1) between the electrode contacts (13, 14) and the electrode The distance (L2) between the side shoulders (15, 152) and the arc discharge device shoulders (17, 172) is determined according to the...

Embodiment 2

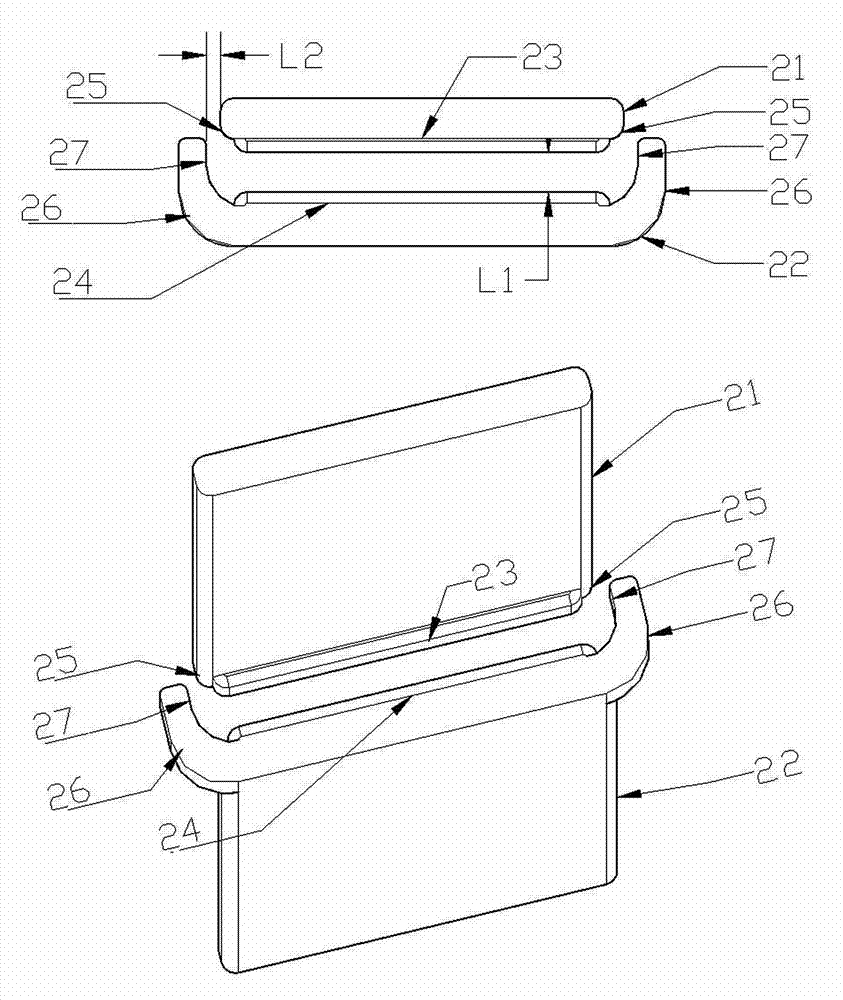

[0019] Example 2: figure 2 Shown is a new type of high-current reed switch contact structure, which is a schematic diagram of the reed switch normally open state. It consists of at least one set of elastic reed electrodes (21, 22) or at least one fixed electrode (22) and one elastic reed electrode (21); the electrodes (21, 22) are made of conductive materials, One of the end faces overlaps with each other, and there are contacts (23, 24) on the opposite surface of the overlapped ends, wherein the reed electrode (22) has a protruding arc discharge device (26) on the side of the contact end; the reed electrode contact There is a certain gap between (23, 24); the frontal distance (L1) between the electrode contacts (23, 24) and the distance (L2) between the electrode side shoulder (25) and the arc discharge device shoulder (27) Press the switch The relevant working parameters such as the specific breaking current voltage and breakdown voltage are determined, and the frontal d...

Embodiment 3

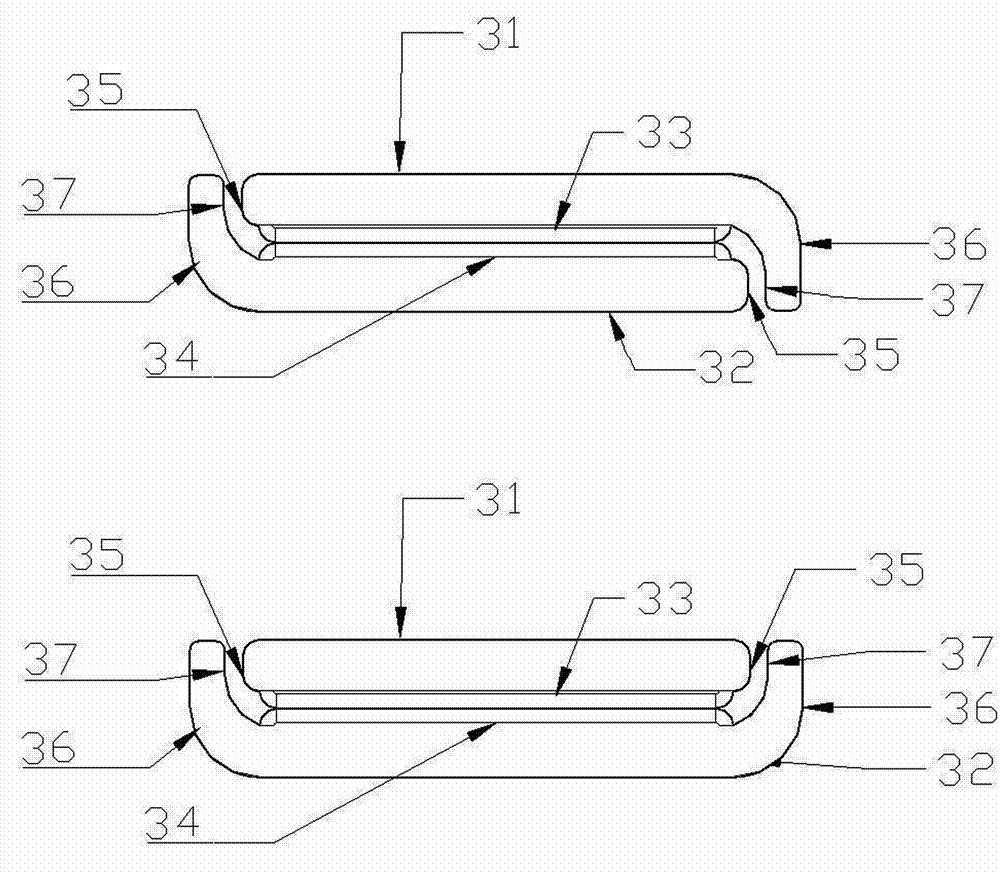

[0021] Example 3: image 3 Shown is a new type of high current reed switch contact structure, which is a schematic diagram of the reed switch normally closed state. It consists of at least one set of elastic reed electrodes (31, 32) or at least one fixed electrode (32 or 31) and one elastic reed electrode (31 or 32); the reed electrodes (31, 32 ) is made of conductive material, one end face of which is overlapped, and there are contacts (33, 34) on the opposite surface of the overlapped ends, wherein the reed type electrode (31 or 32) has a protruding arc discharge device on the side of the contact end ( 36); the end faces of the reed electrodes (31, 32) overlap each other, and the two electrode contacts (33, 34) are tightly closed.

[0022] The description of the switching process of the two electrodes ( 31 , 32 ) between the closed state and the open state and the movement process of the arc between the contacts is similar to the opening and closing process of the first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com