Electrical discharge machining apparatus

A technology of electrical discharge machining and power supply, which is applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., can solve the problem of difficult discharge and other problems, achieve the effect of preventing short circuit, improving processing accuracy and processing efficiency, and suppressing the reduction of discharge frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

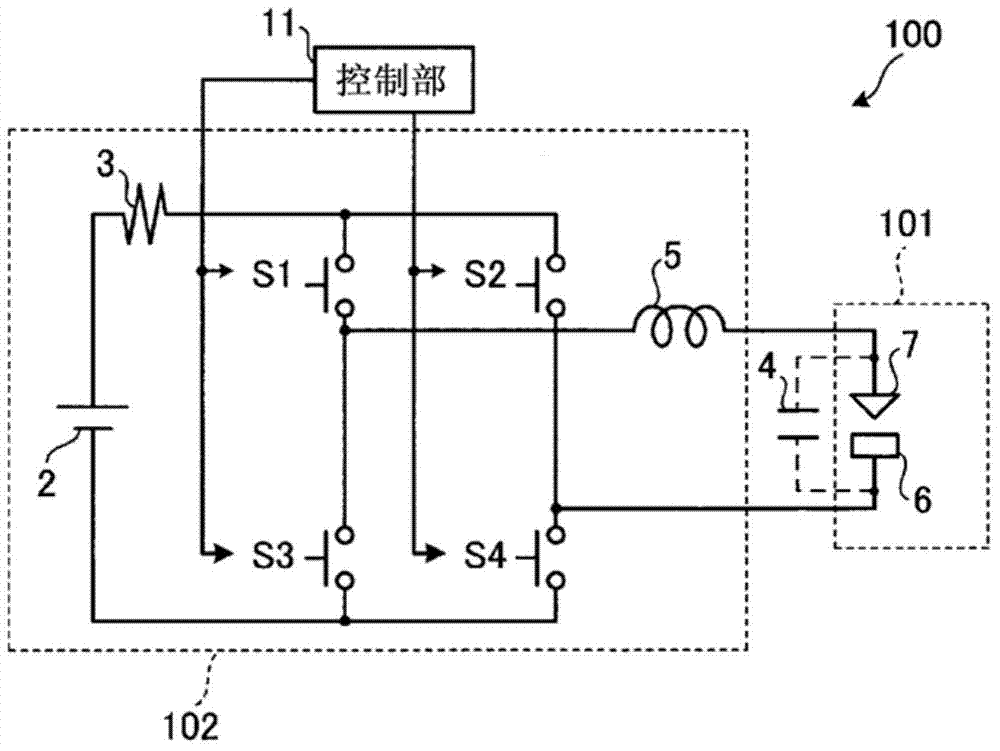

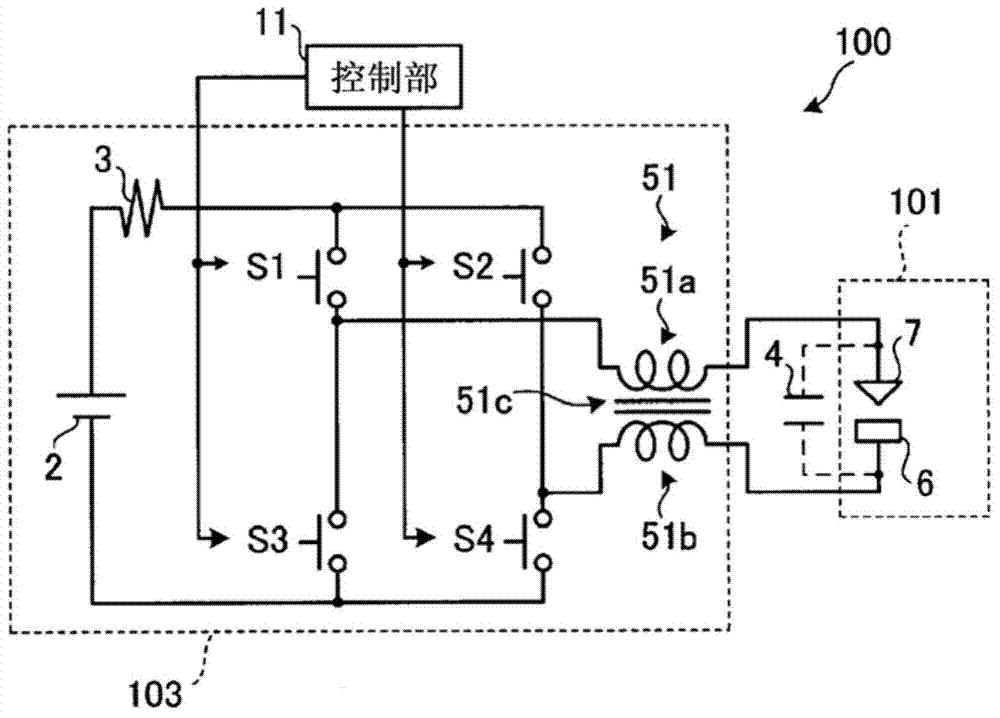

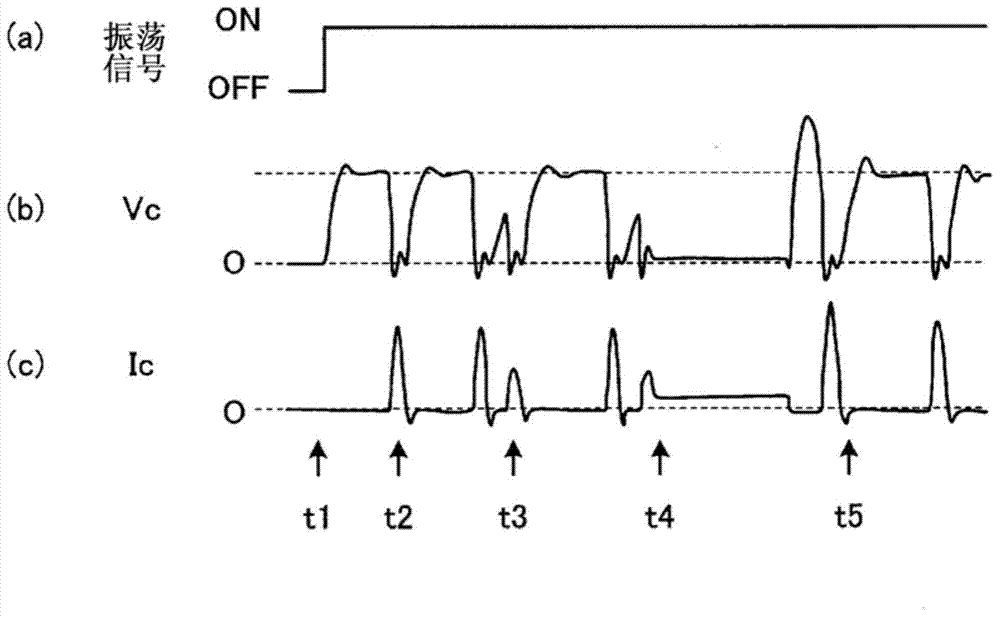

[0037] use figure 1 , figure 2 The electrical discharge machining device 100 according to Embodiment 1 will be described. figure 1 It is a diagram showing a configuration example of the electrical discharge machining device 100 . figure 2 It is a diagram showing another configuration example of the electrical discharge machining device 100 .

[0038] For example, if figure 1 As shown, the electrical discharge machining device 100 includes an inter-electrode gap 101 , a power supply unit 102 , and a control unit 11 .

[0039] Inter-electrode gap 101 is formed by electrode 7 and workpiece 6 . The electrode 7 and the workpiece 6 face each other across a machining gap. The workpiece 6 is grounded to the ground potential, for example. The capacitance 4 existing between the electrode 7 and the workpiece 6 can be inserted arbitrarily, and a parasitic capacitance existing in a mechanical structure such as a cable can also be used.

[0040] The capacitance 4 provided in the in...

Embodiment approach 2

[0079] Next, use Figure 5 , Image 6 An electric discharge machining device 100i according to Embodiment 2 will be described. Figure 5 It is a figure which shows the structural example of 100i of electrical discharge machining apparatuses. Image 6 It is a figure which shows another structural example of the electrical discharge machining apparatus 100i. Hereinafter, description will focus on parts different from Embodiment 1. FIG.

[0080] In Embodiment 1, the on-pulse time width ΔTon and the off-time width ΔToff in the switching mode (oscillating signal) are, for example, values obtained through experiments in advance. On the other hand, in the second embodiment, the on-pulse time width ΔTon and the off-time width ΔToff in the switching mode (oscillating signal) are dynamically adjusted according to the state of the inter-electrode space 101 .

[0081] For example, if Figure 5 shown, with figure 1 Compared with the shown electric discharge machining device 100 , t...

Embodiment approach 3

[0101] Next, use Figure 8 and Figure 9 An electrical discharge machining device 100j according to Embodiment 3 will be described. Figure 8 It is a figure which shows the structural example of 100 j of electrical discharge machining apparatuses. Figure 9 It is a figure which shows another structural example of the electrical discharge machining apparatus 100j. Hereinafter, description will focus on portions different from Embodiment 2. FIG.

[0102] In Embodiment 2, the on-pulse time width and the off-time width in the switching mode are adjusted so that the input energy to the inter-electrode space 101 is substantially constant based on the state of the inter-electrode space 101 detected by the detection unit 10i. On the other hand, in Embodiment 3, according to the state of the inter-electrode 101 detected by the detection part 10i, the on-pulse time width and off-time width in switching mode are adjusted so that the short circuit of the inter-electrode 101 can be elim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com