Discharge mechanism and discharge method of energy-level molecular material cell tearing equipment

A technology of molecular material and discharging mechanism, which is applied in the chemical/physical/physical chemical process of applying energy, microsphere preparation, microcapsule preparation, etc. It can solve the problem of small-scale production, high equipment demand, and temperature difference crushing cost. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

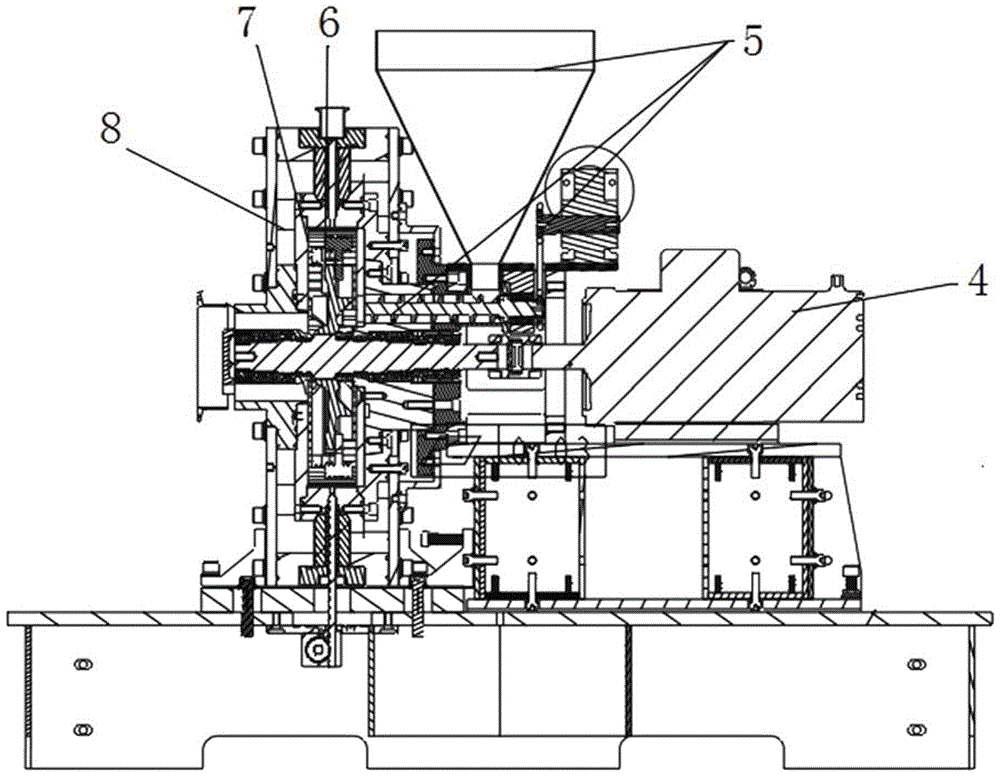

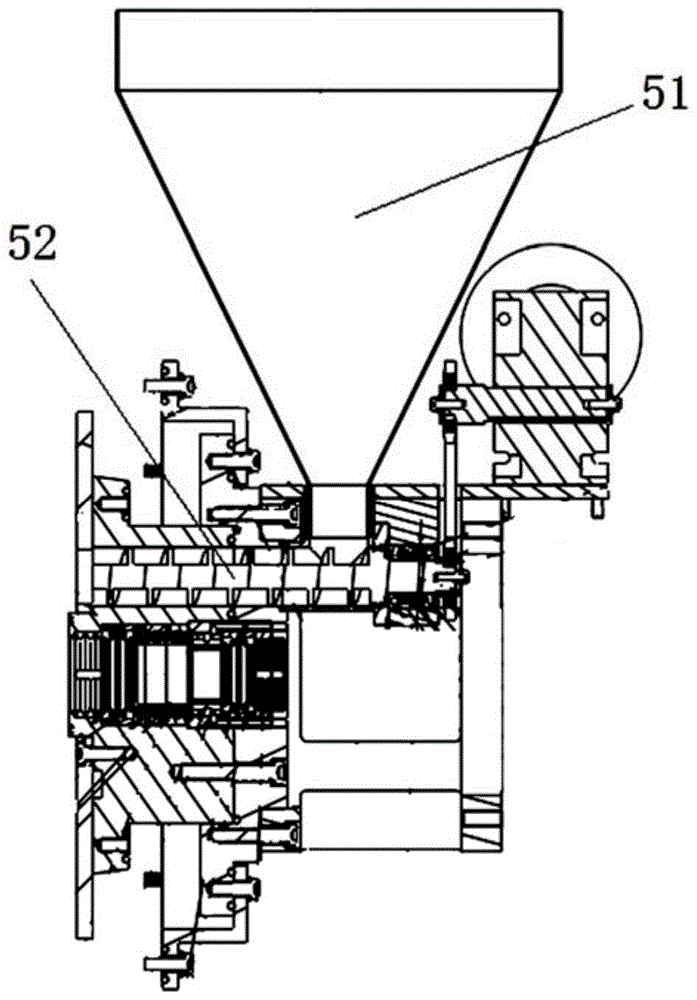

[0039] In order to facilitate those skilled in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

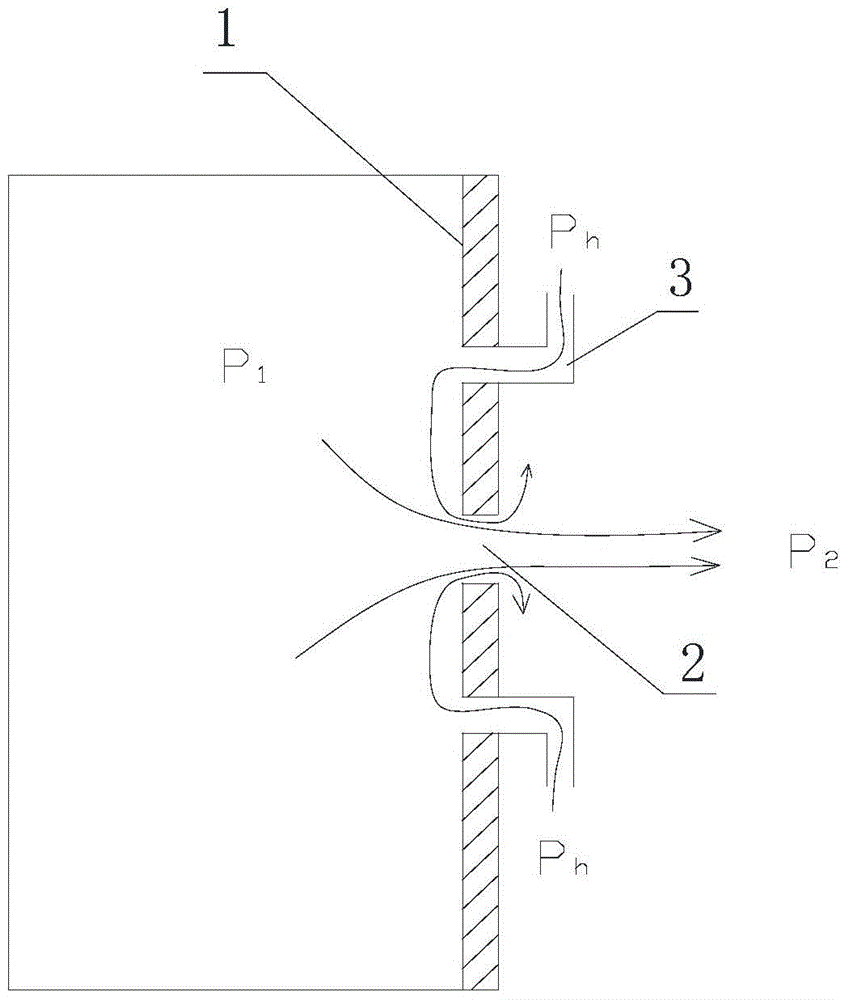

[0040] Such as figure 1 As shown, a discharge mechanism of an energy-level molecular material cell tearing device includes: a baffle 1, at least one material outlet 2 passing through the baffle 1, and at least two negative feedbacks arranged around the material outlet 2 Pressure regulator port 3.

[0041] The specific working principle is: set the baffle plate 1 on the energy field cavity of the cell tearing equipment, and act as one side of the energy field cavity. In the energy field cavity, the centrifugal force and centripetal force are used to make the material with large mass thrown by the centrifugal force. to the edge of the energy field cavity; under the action of the pressure difference, the centripetal force mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com