A gear rotary ball adding machine

A gear and ball machine technology, applied in grain processing, etc., can solve the problems of balls not falling down, single types, and inapplicability, and achieve the effects of not being easy to jam or block balls, high ball adding efficiency, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

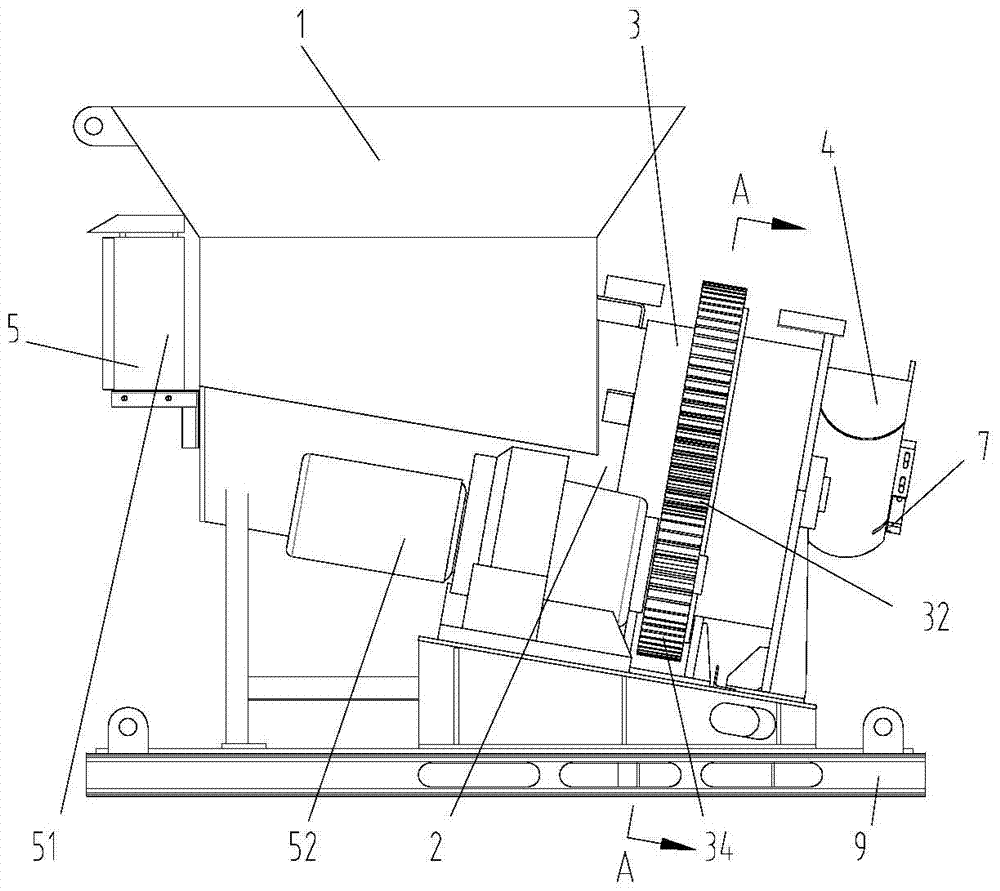

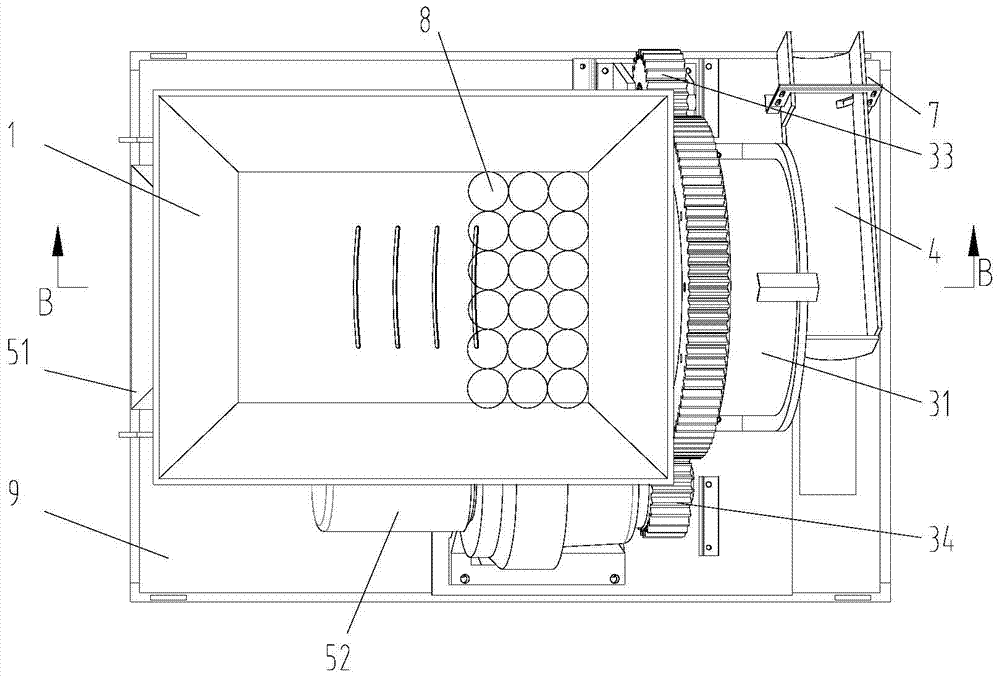

[0038] A gear rotary ball adding machine, comprising a ball storage bin 1 arranged vertically with its ball outlet located at the lowermost end, a slideway arranged obliquely downward and whose upper end communicates with the ball outlet of the ball storage bin 1 2. The goal mechanism 3 communicated with the lower end of the slideway 2, the ball unloading device 4 connected to the goal mechanism 3, the power part 5, the baffle plate 6 and the counter 7, the whole device is arranged on the base 9 , see figure 1 , figure 2 , image 3 as well as Figure 4 , the overall structure is simplified.

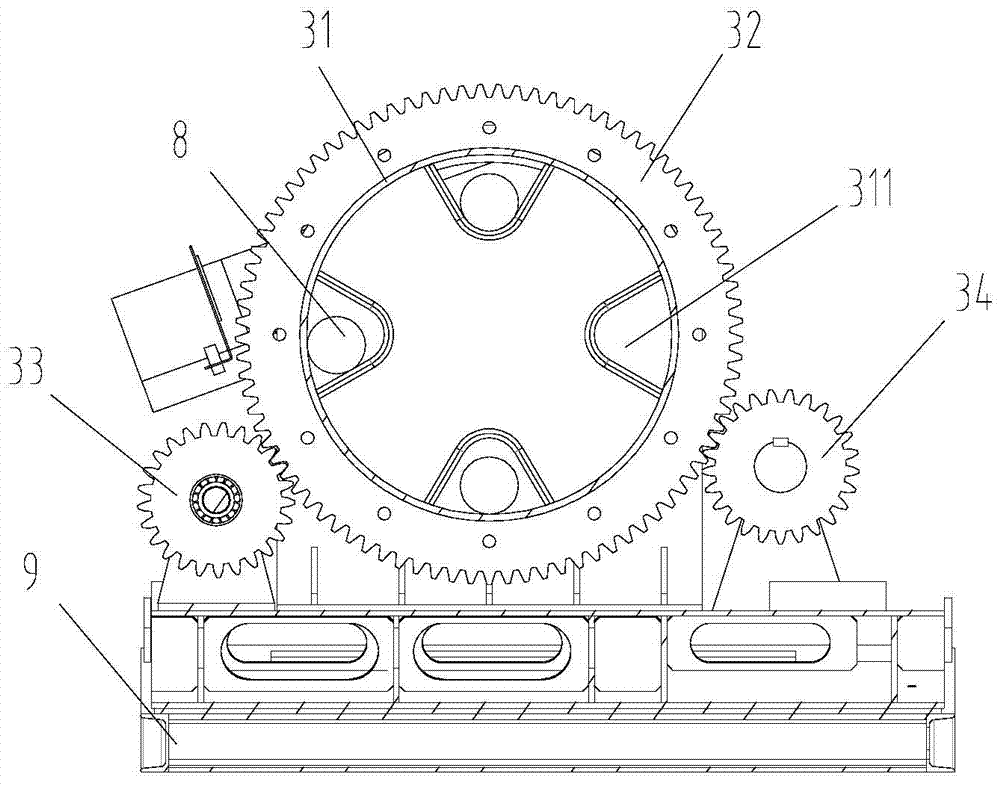

[0039]Described ball mechanism 3 comprises the cylinder 31 that first end is connected with the lower end of described slideway 2 and its second end portion is sealed (cylinder 31 is inclined to be arranged, and the central axis of described cylinder 31 and described slideway 2), the large gear 32 coaxially arranged on the outer wall of the drum 31, the support gear 33 for supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com