Automobile instrument automatic pointer pressing system

A technology for automobile instruments and instrument panels, applied in metal processing, metal processing equipment, hand-held tools, etc., can solve problems such as lack of control, inability to control the angle of the pointer, and difficulty in ensuring the alignment of the pointer and the motor shaft of the instrument.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below by specific embodiment, in conjunction with accompanying drawing, the technical solution of the present invention is described in further detail:

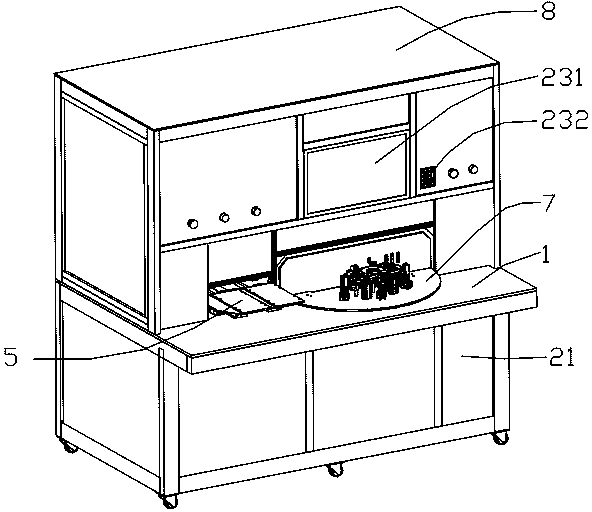

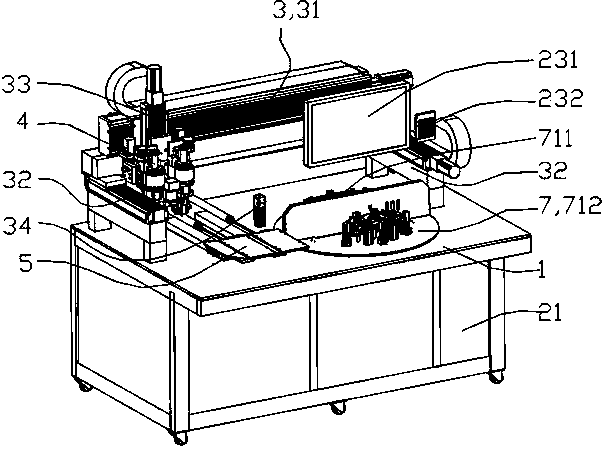

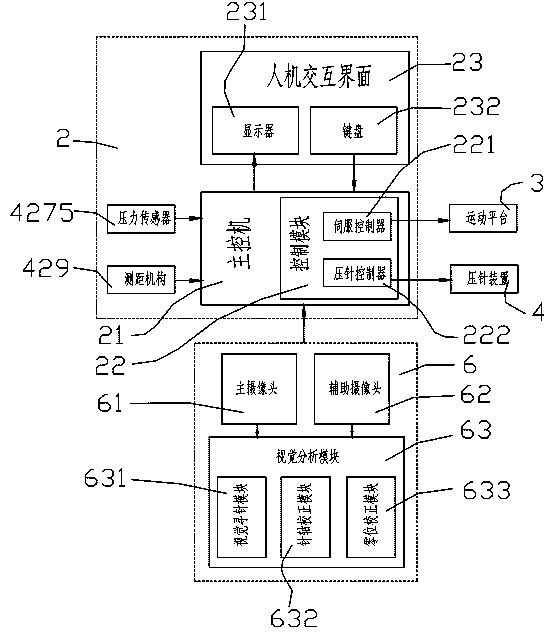

[0026] see figure 1 , figure 2 and image 3 , an automatic needle pressing system for an automobile instrument, comprising a main control system 2, a needle pressing device 4 controlled by the main control system 2, a motion platform 3, a feeding device 5 and a clamping device for clamping an instrument panel 9 to be pressed device7. The main control system 2 includes a main control machine 21 set on a frame 1 , a control module 22 set in the main control machine 21 , and a visual analysis positioning system 6 . The main control machine 21 includes a human-computer interaction interface 23 including a display 231 and an input keyboard 232 arranged on the stand 1 . The control module 22 includes a servo controller 221 for controlling the motion platform 3 and a needle pressing controller 222 for controlling the nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com