Welding method free of bead trimming and double-head cutting saw with automatic processing function

A welding method and automatic processing technology, applied in metal processing, metal processing equipment, sawing machine devices, etc., can solve the problems of destroying the overall aesthetics of doors and windows, and achieve the effect of improving the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

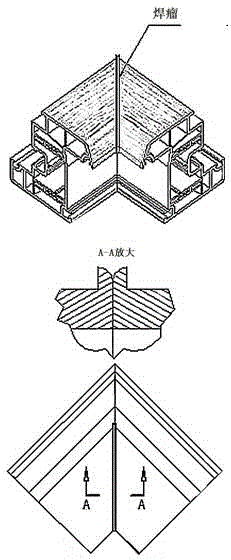

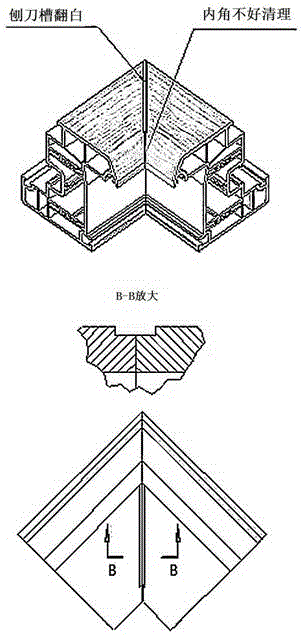

[0037] This embodiment discloses a processing such as Figure 4 The non-clearing fillet welding method of the shown seamless fillet is a clearing-free fillet welding method for uPVC doors and windows, which welds the fillet; ; The relative assembly inner surface of the left side welding unit and the right side welding unit is a cutting surface; before the welding of the left side welding unit and the right side welding unit, the outer surface of the outer contour of the cutting surface is milled inward by a cutting saw , width 1-4mm, depth 1.5-3mm, grooves are formed on the outer surface of the outer contour, so that the material melted on the cutting surface does not overflow to the surface during welding, and stays in the groove without forming weld bumps, and the appearance is good.

[0038] This embodiment also discloses a double-head cutting saw with automatic processing function for cutting profiles in the above process (such as Figure 5-8shown), including: bed 1, fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com