Pricking-prevention low-hysteresis tire

A tire and anti-puncture technology, applied in tire parts, transportation and packaging, vehicle parts, etc., can solve problems such as low rolling resistance, impact on vehicle safety, oil and electricity consumption, etc., to reduce power loss and improve safety And economy, the effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

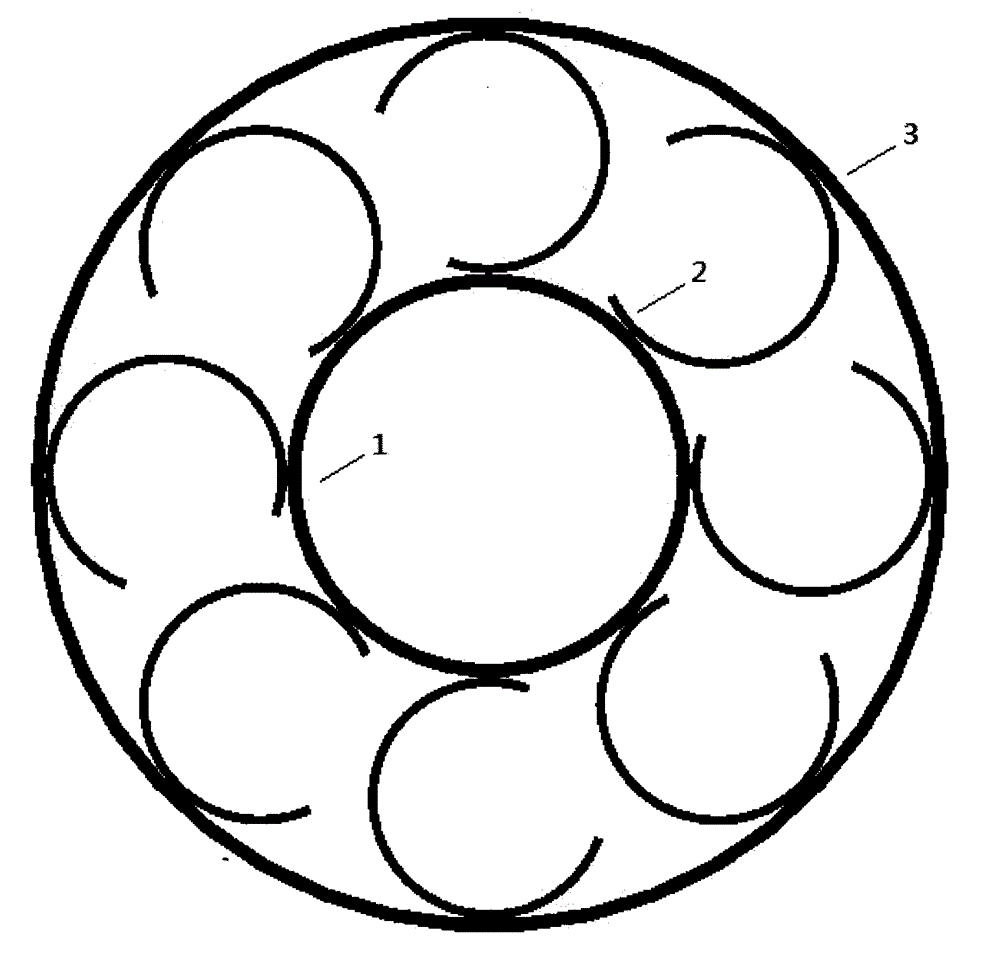

[0009] As shown in Fig. 1, the anti-puncture low-hysteresis tire consists of an inner ring (1), a curved beam support (2) and a rubber tire (3). The curved beam support can be arranged between the inner ring (1) and the rubber tire (3) by means of fixed connection, welding, or bonding, and can also be integrated with the inner ring (1) to provide support and The role of power transmission.

[0010] The inner ring (1) is generally circular and plays the role of connecting the rim and the curved beam support (2), and the shape design is carried out according to the needs of the connection method, such as drilling, adding lugs, etc. The curved beam support (2) is composed of several curved beam members of the same shape. These curved beam members are centered on the center of the tire and arranged between the inner ring (1) and the rubber tire (3) in a rotational symmetry. According to the selected Component materials, loads and circumferential power transmission require the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com