Chassis online overturning equipment

A technology for flipping equipment and chassis, which is applied to motor vehicles, transportation and packaging, etc. It can solve problems such as increased installation difficulty, safety hazards, and low standardization, and achieves the effects of eliminating safety hazards, reducing bumps, and reducing human labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

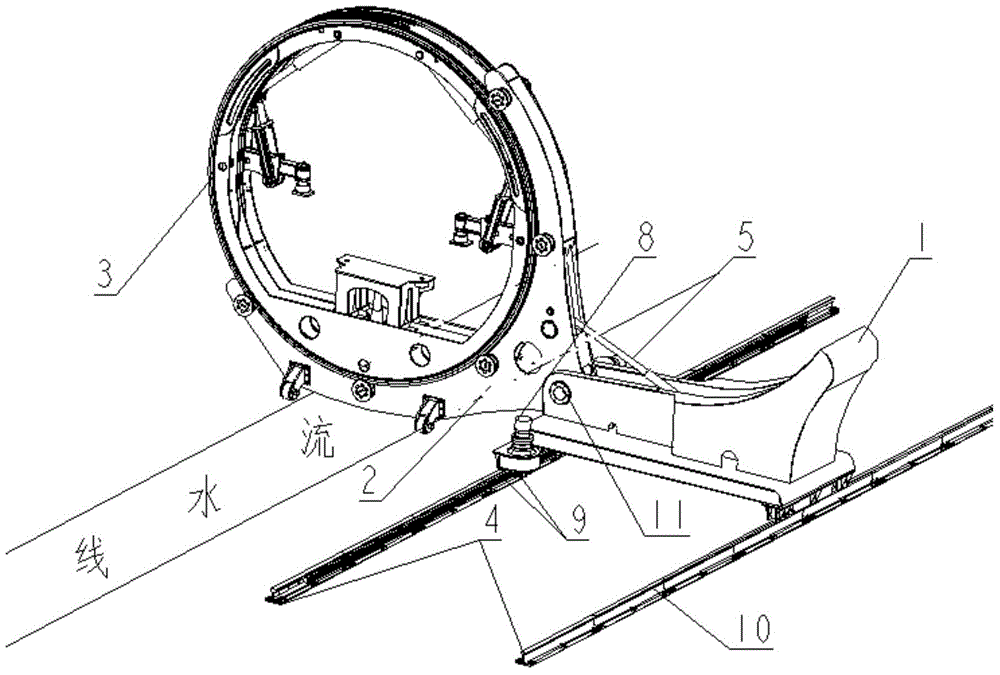

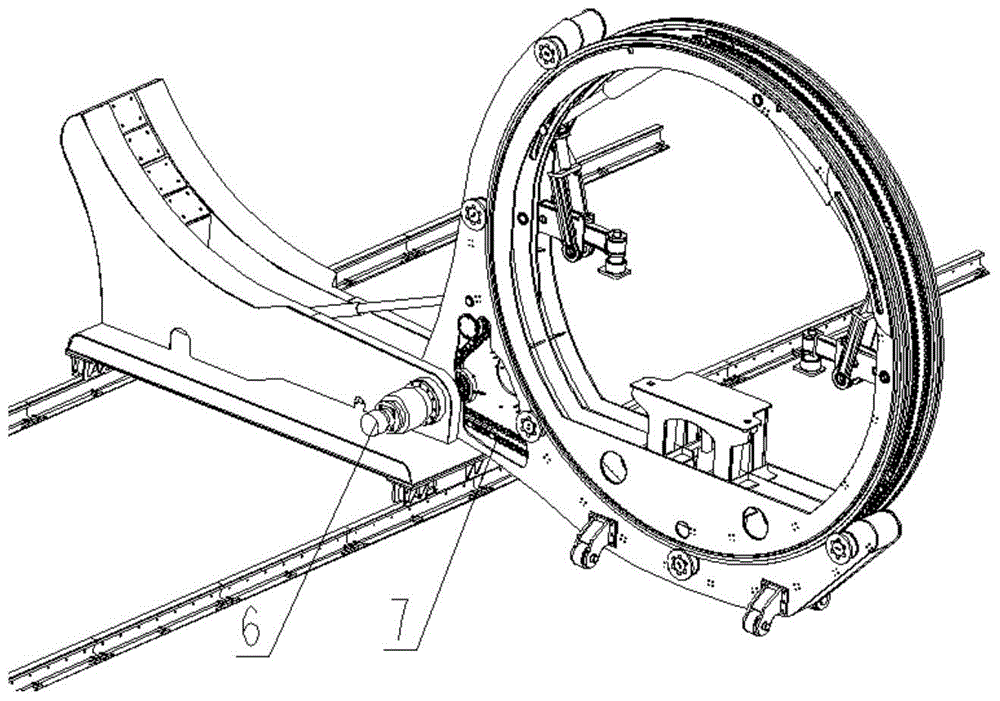

[0033] Such as figure 2 with image 3 As shown, a chassis on-line flipping device,

[0034] It includes a base 1, a bracket 2, a turning ring 3 mounted on the bracket 2 and capable of rotating around the bracket 2, and a foundation 4;

[0035] The base 1 is installed on the foundation 4 and can walk on the guide rail 10 in the foundation 4;

[0036] The bracket 2 is connected to the base 1 through the rotating shaft 11, and can rotate around the rotating shaft 11 relative to the base 1;

[0037] Wherein, the shape and size of the bracket 2 match the turning circle 1, and the bottom is equipped with walking wheels, which can walk on the ground together with the base 1.

[0038] The travel motor 8 installed on the base 1 rotates and drives the rack and pinion mechanism 9 connected with the travel motor 8, driving the whole equipment to travel in the foundation 4;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com