Auxiliary device for overhauling top of transformer

A technology of auxiliary devices and transformers, which is used in lifting devices, switching devices, transportation and packaging, etc., can solve the problem of difficult to find the hanging point seat belt for seat belts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

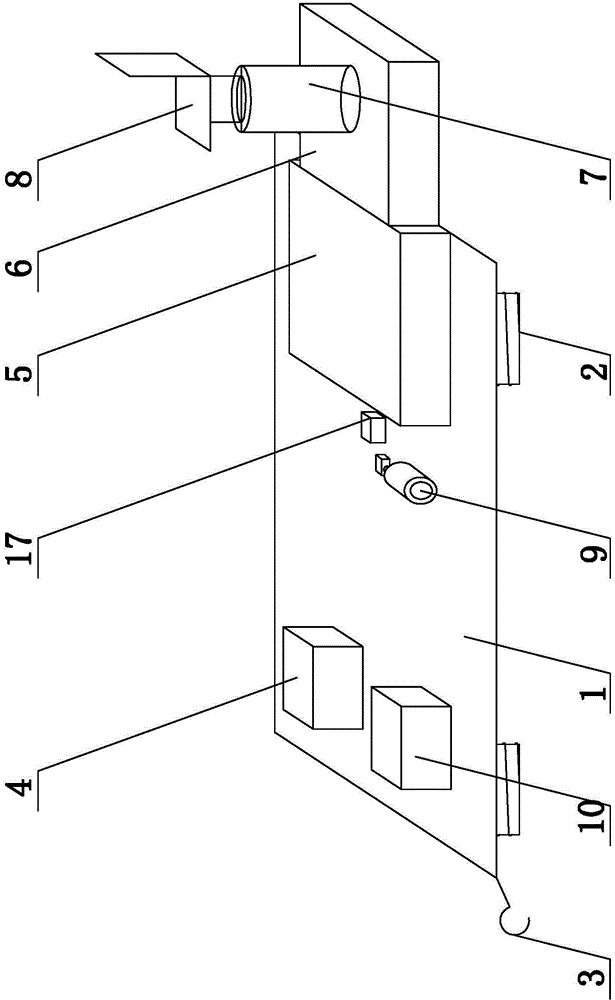

[0018] Embodiment 1: as figure 1 As shown, the transformer top maintenance auxiliary device described in the present invention includes a base plate 1, an electromagnet 2 and a hook 3 are provided at the bottom of the base plate 1, a power supply 4 is provided on the top surface of the base plate 1, and the electromagnet 2 is connected to the power supply 4 through a control device 17. , the top surface of the bottom plate 1 is provided with a sleeve 5 and a horizontal rod 6, one end of the horizontal rod 6 is inserted in the sleeve 5, the other end of the horizontal rod 6 is provided with a hydraulic cylinder 7, and the piston rod of the hydraulic cylinder 7 is provided with a seat 8. The base plate 1 is provided with an oil pump 9, an oil tank 10 and a solenoid valve 11. The two oil ports of the hydraulic cylinder 7 are connected to two ports on one side of the solenoid valve 11, and one of the two ports on the other side of the solenoid valve 11 is connected through the oil ...

Embodiment 2

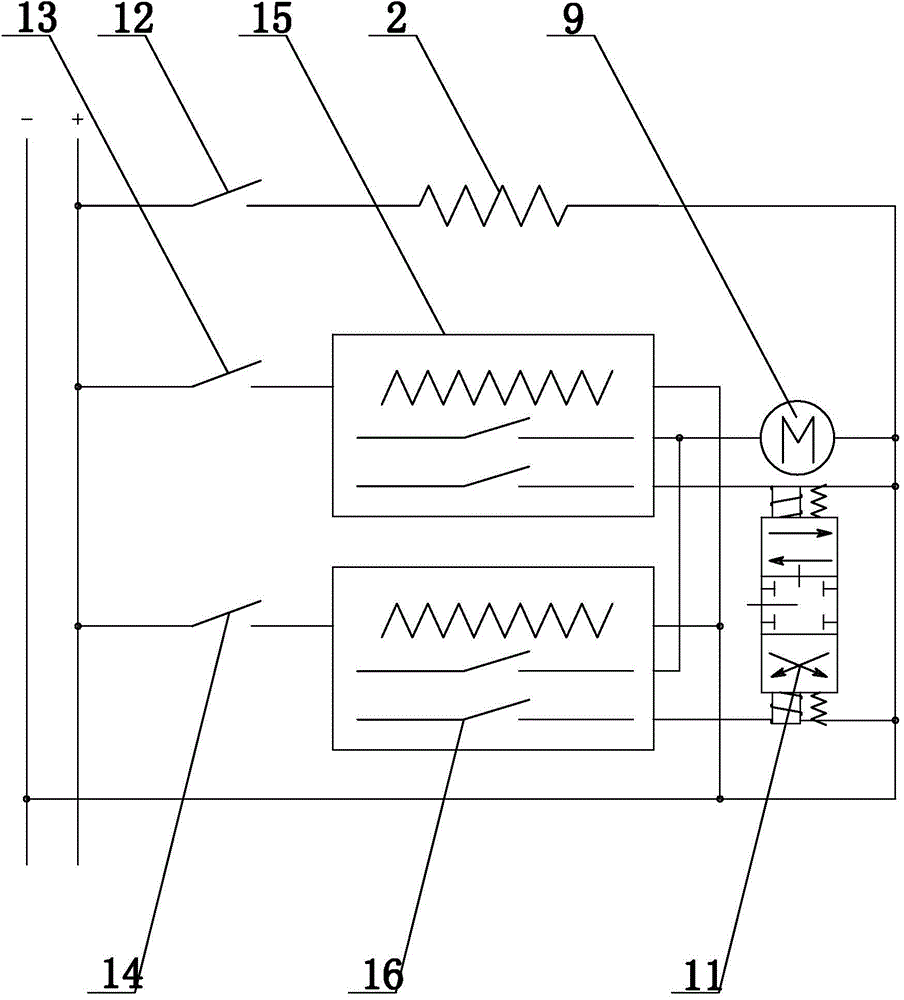

[0019] Embodiment 2: on the basis of the structure described in embodiment 1, as figure 2 As shown, the control device 17 includes a switch 12, a switch B13, a switch C14, a relay A15 and a relay B16. One end of the switch 12 is connected to the power supply 4, and the other end is connected to the coil of the electromagnet 2, a coil of the solenoid valve 11 and a coil of the oil pump 9. The power supply end is connected to the power supply 4 through the two normally open contacts of the relay A15, one end of the coil of the relay A15 is connected to the positive pole of the power supply 4 through the switch B13, and the other end is connected to the negative pole of the power supply 4; the other coil of the solenoid valve 11 and the oil pump 9 The power supply end is connected to the power supply 4 through two normally open contacts of the relay B16, one end of the coil of the relay B16 is connected to the positive pole of the power supply 4 through the switch C14, and the ot...

Embodiment 3

[0020] Embodiment 3: On the basis of the structure described in Embodiment 2, a row of holes is provided on the top surface of the sleeve 5, a row of screw holes is provided at the corresponding position of the horizontal rod 6, and an anti-falling net is provided on the bottom surface of the other end of the horizontal rod 6.

[0021] Operation steps and working principle:

[0022] In the transformer top maintenance auxiliary device, the number of electromagnets 2 on the bottom surface of the bottom plate 1 is five, and the five electromagnets 2 are respectively located at the four corners and the center of the bottom surface, which ensures that the electromagnets 2 can be firmly Firmly absorb the iron transformer shell, first hoist the present invention to the top of the transformer with a crane, and operate the control device 17 to energize the electromagnet 2, adsorb the bottom plate 1 on the top of the transformer, and then hang the hook in a firm position, Avoid unexpect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com