Production method of mushroom dreg and cow dung composite organic fertilizer

A production method and technology of organic fertilizer, applied to the preparation of organic fertilizer, organic fertilizer, treatment of biological organic parts, etc., to achieve the effect of simple method, huge economic and social benefits, and soil improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The present invention in concrete implementation, comprises the following steps:

[0019] (1) De-bag and crush the fungus residue: select the mushroom residue after the edible fungus is cultivated in the edible fungus industry, air-dry for 24 hours after removing the bag, and crush it into fungus residue particles with a particle size of 6-18mm;

[0020] (2) Mixing: Cow dung is used as a fermented and decomposed bacterial agent and mixed with fungus residue particles. The volume ratio of fungus residue particles to cow dung is 0.5:1;

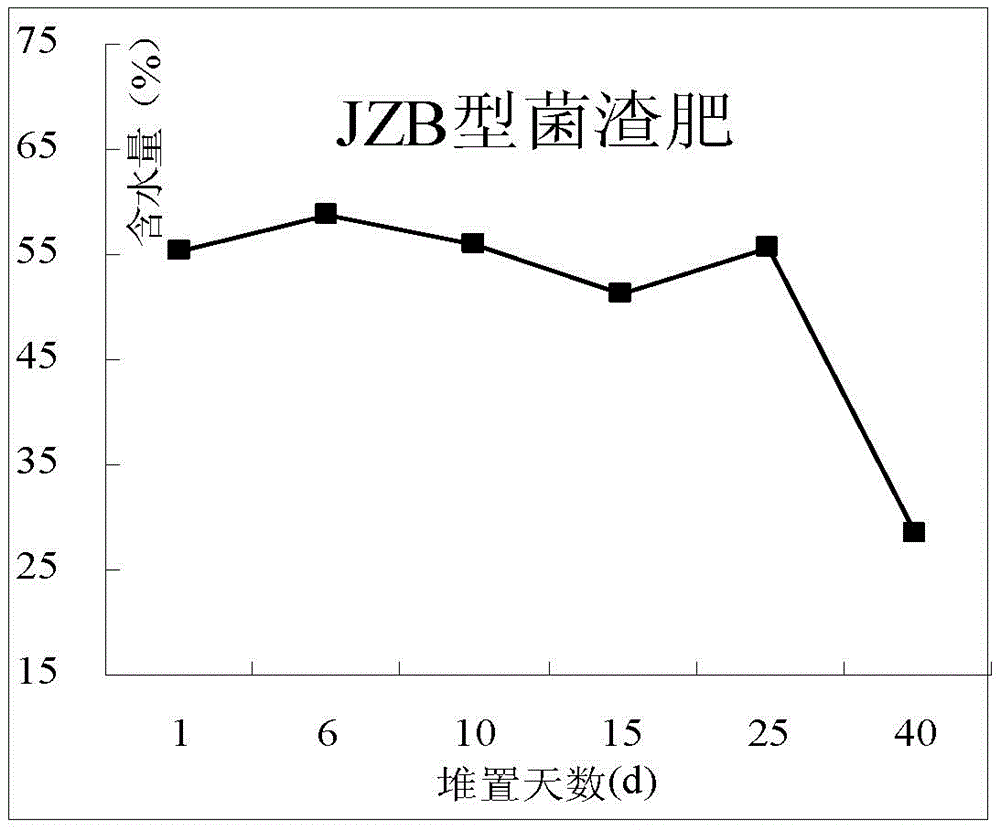

[0021] (3) Deployment: Add the mixed cow dung and bacteria residue particles into the organic fertilizer fermentation agent, the amount of which is 0.01% of the weight sum of cow dung and bacteria residue particles, stir evenly, and add water to make the weight water content 51 -54%, blended into a compound fermentation material;

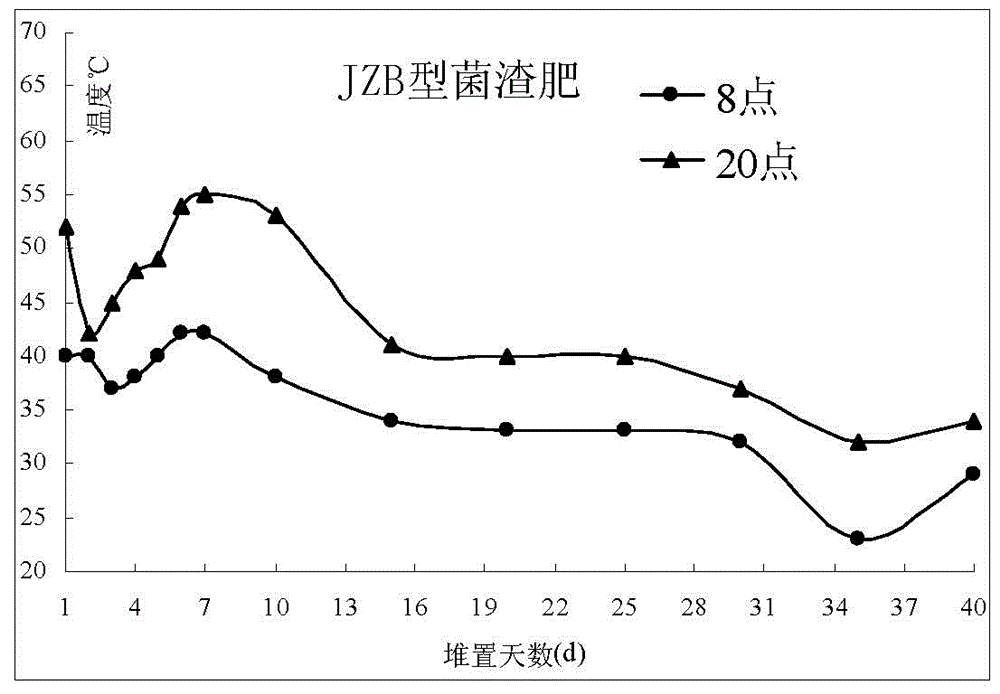

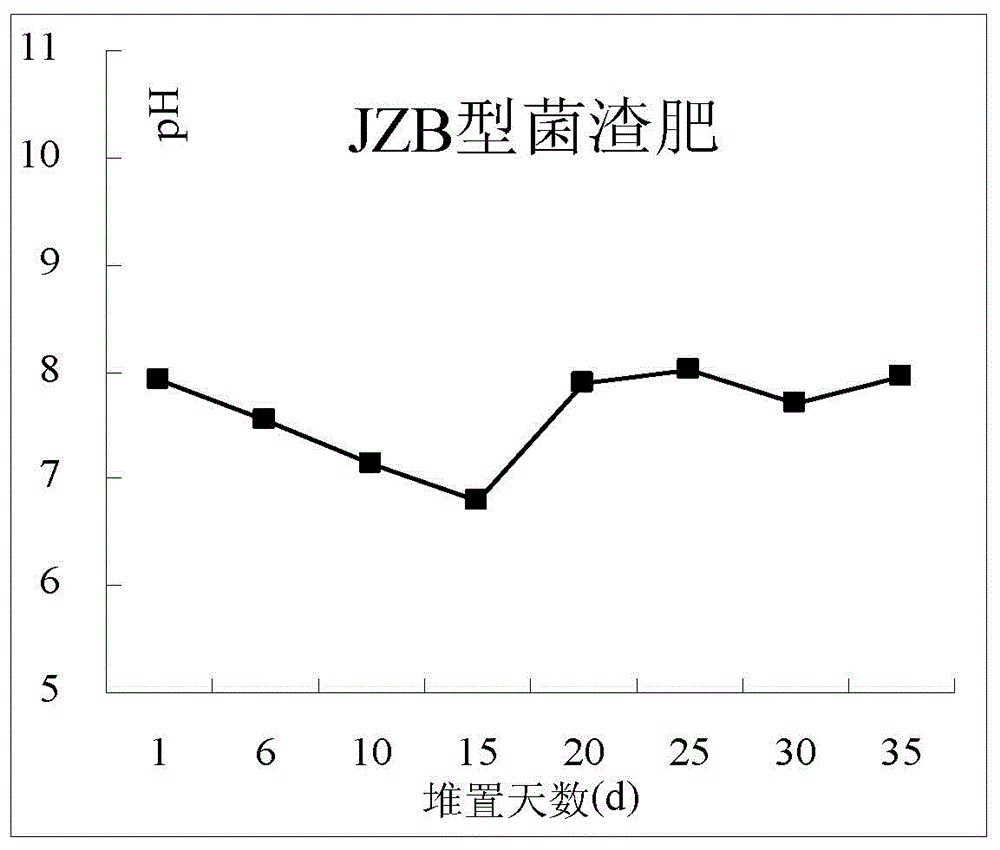

[0022] (4) Heap building: build the fermented material into a pile with a length of 3-5m, a width of 1.6-1....

Embodiment 2

[0025] The present invention also can be realized by following steps in concrete:

[0026] (1) De-bag and crush the fungus residue: select the mushroom residue after the edible fungus is cultivated in the edible fungus industry, air-dry for 24 hours after removing the bag, and crush it into fungus residue particles with a particle size of 10-15mm;

[0027] (2) Mixing: Cow dung is used as a fermented and decomposed bacterial agent and mixed with fungus residue particles. The volume ratio of fungus residue particles to cow dung is 0.4︰0.9;

[0028] (3) Deployment: Add the mixed cow dung and bacteria residue particles into the organic fertilizer fermentation agent. The amount added is 0.02% of the weight sum of the cow dung and bacteria residue particles. Stir evenly and add water to make the water content by weight 52. -53%, blended into a compound fermentation material;

[0029] (4) Heap building: build the fermented material into a stockpile with a length of 4-5m, a width of ...

Embodiment 3

[0032] The present invention can also be realized by the following steps:

[0033] (1) De-bag and crush the fungus residue: select the mushroom residue after the edible fungus is cultivated in the edible fungus industry, air-dry for 24 hours after removing the bag, and crush it into fungus residue particles with a particle size of 11-13mm;

[0034] (2) Mixing: Cow dung is used as a fermented and decomposed bacterial agent and mixed with fungus residue particles. The volume ratio of fungus residue particles to cow dung is 0.6:1.1;

[0035] (3) Deployment: Add the mixed cow dung and bacteria residue particles into the organic fertilizer fermentation agent. The amount added is 0.015% of the weight sum of the cow dung and bacteria residue particles. Stir evenly and add water to make the water content by weight 52 -53%, blended into a compound fermentation material;

[0036] (4) Heap building: build the fermented material into a stockpile with a length of 4m, a width of 1.8m, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com