Concrete surface protection nano paint and manufacturing technique thereof

A technology of concrete surface and nano-coating, applied in anti-corrosion coatings, coatings, etc., can solve the problems of insufficient durability protection, high self-shrinkage and brittleness of concrete, and achieve high corrosion resistance and high wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of technology of preparing concrete surface protective nano-coating, this technology comprises the steps:

[0019] 1) Add 29Kg of n-butanol into the reaction kettle, then add 24Kg of nano silicon dioxide while stirring, and stir for 30 minutes.

[0020] 2) Add 14Kg of trimethoxysilane and 11Kg of isobutyltriethoxysilane into the reaction kettle, and stir for 1 hour.

[0021] 3) Add 5.5Kg of butyl acetate and 7.5Kg of ethyl orthosilicate into the reaction kettle, and stir for 1 hour.

[0022] 4) Add 3Kg of dodecyl alcohol ester into the reaction kettle and stir for 30 minutes to obtain the concrete surface protective nano-coating.

[0023] 5) Sealing and filling the concrete surface protective nano-coating, the sealing and filling work must be completed within 1 hour.

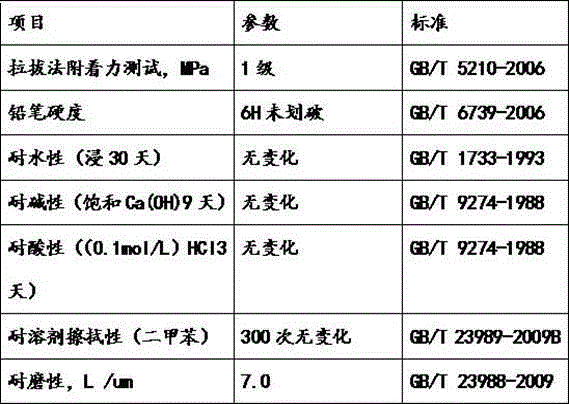

[0024] The prepared concrete surface protective nano-coating is used on the concrete surface, and the experimental test index:

[0025]

Embodiment 2

[0027] A kind of technology of preparing concrete surface protective nano-coating, this technology comprises the steps:

[0028] 1) Add 30Kg of n-butanol into the reaction kettle, then add 25Kg of nano silicon dioxide while stirring, and stir for 30 minutes.

[0029] 2) Add 15Kg of trimethoxysilane and 12Kg of isobutyltriethoxysilane into the reaction kettle, and stir for 1 hour.

[0030] 3) Add 6.0Kg of butyl acetate and 8.0Kg of ethyl orthosilicate to the reaction kettle, and stir for 1 hour.

[0031] 4) Add 4Kg of dodecyl alcohol ester to the reaction kettle and stir for 30 minutes to obtain the concrete surface protective nano-coating.

[0032] 5) Sealing and filling the concrete surface protective nano-coating, the sealing and filling work must be completed within 1 hour.

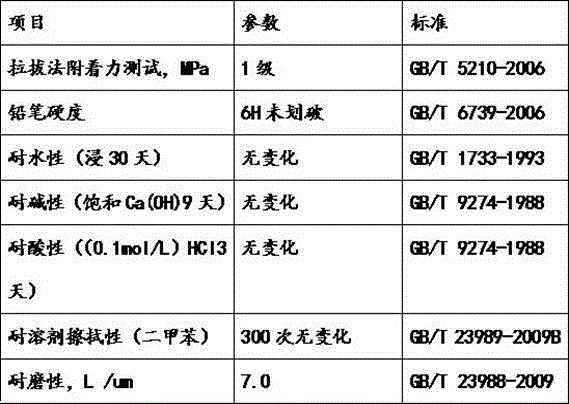

[0033] The prepared concrete surface protective nano-coating is used on the concrete surface, and the experimental test index:

[0034]

Embodiment 3

[0036] A kind of technology of preparing concrete surface protective nano-coating, this technology comprises the steps:

[0037] 1) Add 31Kg of n-butanol into the reaction kettle, then add 26Kg of nano-silica while stirring, and stir for 30 minutes.

[0038] 2) Add 16Kg of trimethoxysilane and 13Kg of isobutyltriethoxysilane into the reaction kettle, and stir for 1 hour.

[0039] 3) Add 6.5Kg of butyl acetate and 8.5Kg of ethyl orthosilicate into the reaction kettle, and stir for 1 hour.

[0040] 4) Add 5Kg of dodecyl alcohol ester into the reaction kettle and stir for 30 minutes to obtain the concrete surface protective nano-coating.

[0041] 5) Sealing and filling the concrete surface protective nano-coating, the sealing and filling work must be completed within 1 hour.

[0042] project parameter standard Pull-out adhesion test, MPa Level 1 GB / T 5210-2006 pencil hardness 6H unbroken GB / T6739-2006 Water resistance (soaked for 30 days) n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com