Vertical cup type freezing reinforcement structure and method at shield tunnel end

A technology for shield tunneling and reinforcement structures, which is applied in tunnels, earthwork drilling, mining equipment, etc., and can solve the problems of reinforcement structures and methods that are difficult to meet engineering requirements, water leakage and sand leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

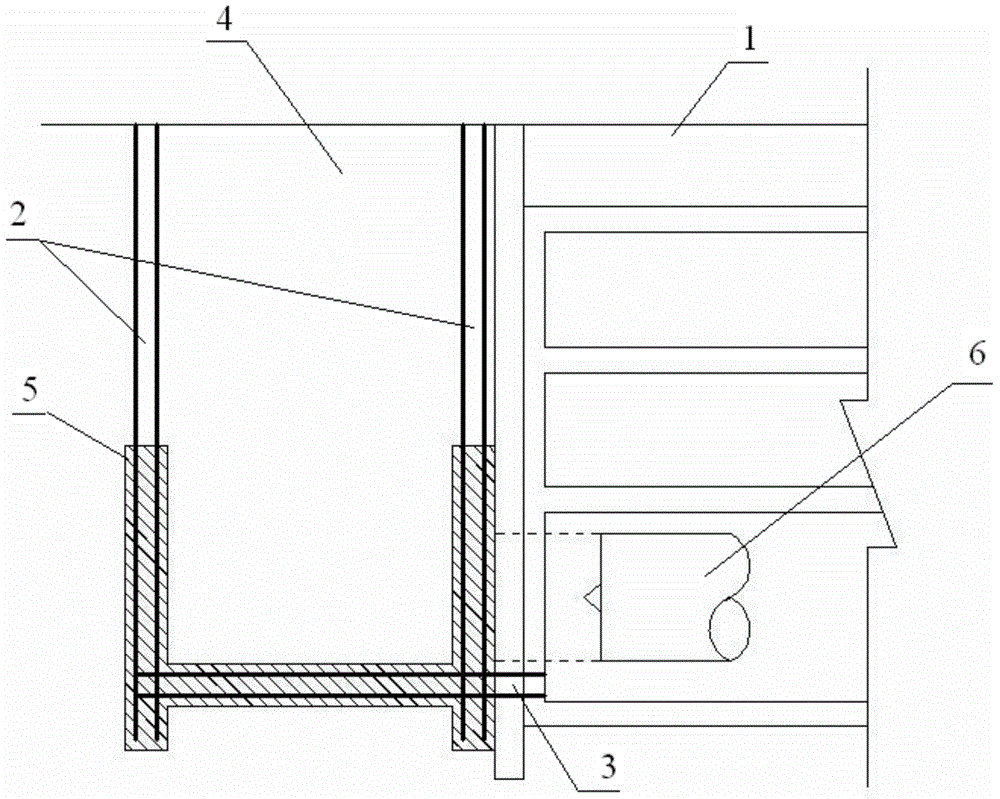

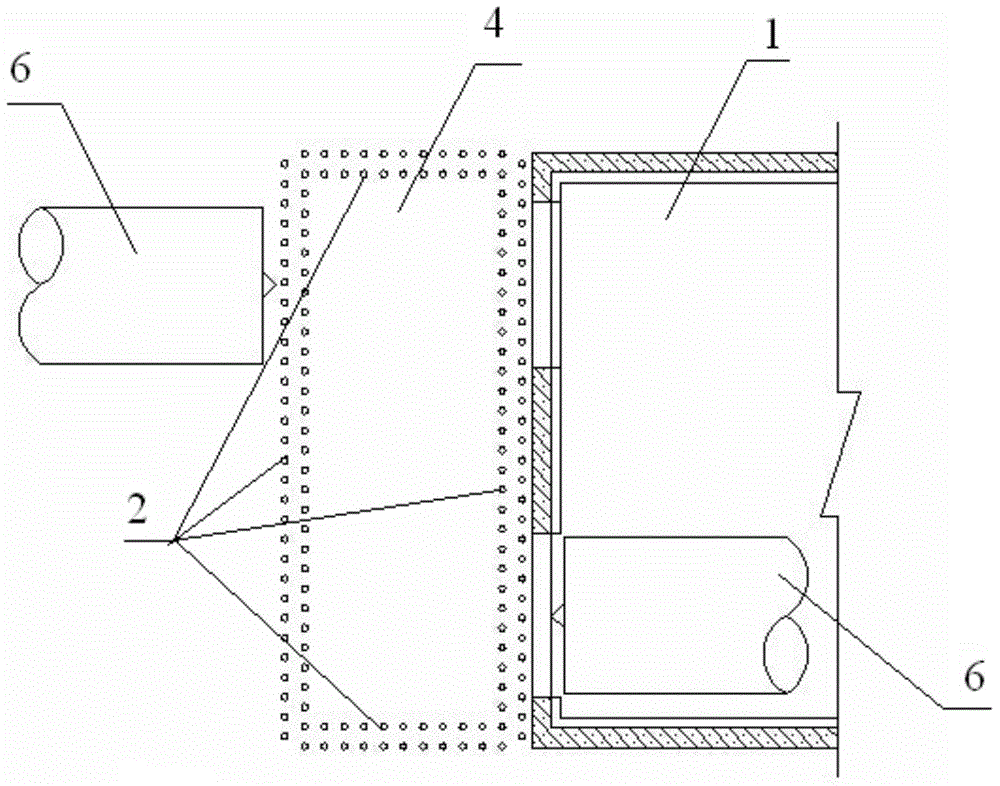

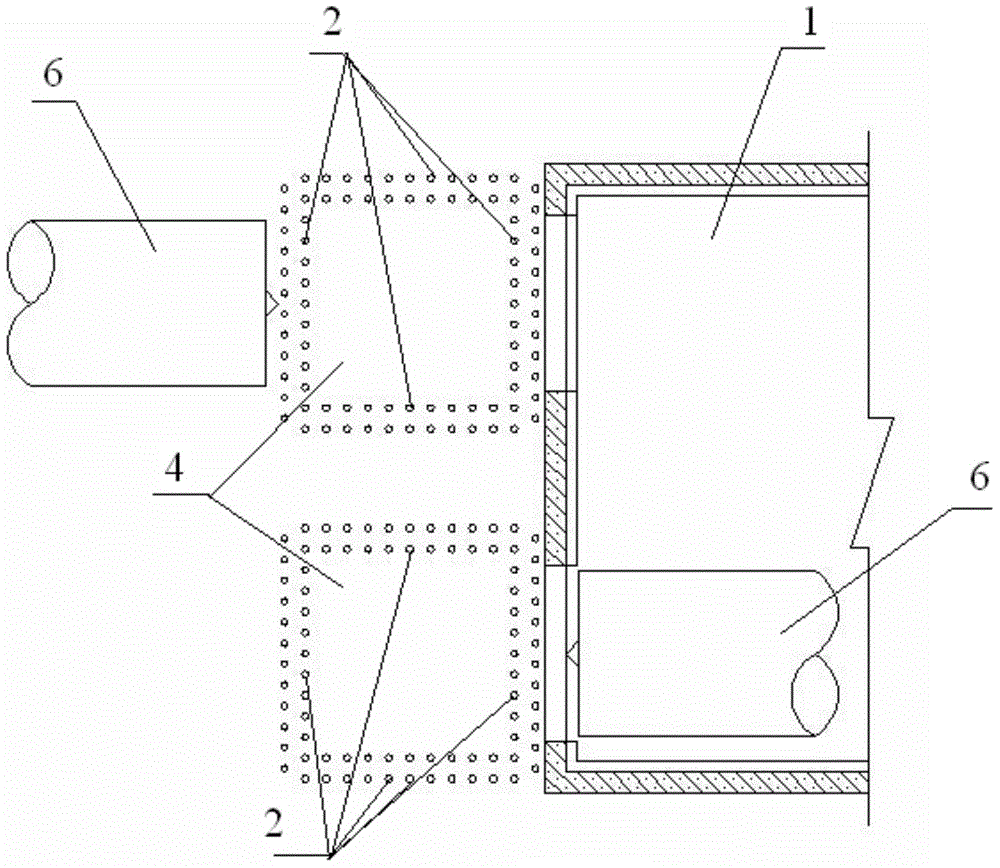

[0128] see figure 1 , figure 2 , image 3 with Figure 4 Shown:

[0129] The vertical cup-shaped freezing reinforcement structure at the end of the shield tunnel provided by the present invention is to arrange vertical freezing pipes 2 in the shape of a "mouth" in the soil body 4 outside the working well 1 at the end of the shield tunnel, and the vertical freezing pipes 2 are arranged as a " 口" or two "口"-shaped layout forms, and at the same time set the horizontal freezing pipe 3 in the lower part of the soil 4 where the vertical freezing pipe 2 is arranged in the end working well 1, and through the vertical freezing pipe 2 and the horizontal freezing pipe 3. The internal circulating cold medium can form a vertical cup-shaped frozen wall reinforcement 5 in the soil 4 outside the working shaft 1 at the end of the shield tunnel.

[0130] The length of the horizontal freezing pipe 3 inserted into the soil body 4 is equal to the layout width of the vertical freezing pipe 2, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com