Equipment and method for secondary lining of tunnel segment

A secondary lining and tunnel segment technology, applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of complex construction, time-consuming and laborious, insufficient lining thickness, etc., and achieve the effect of simple construction, guaranteed service life and guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

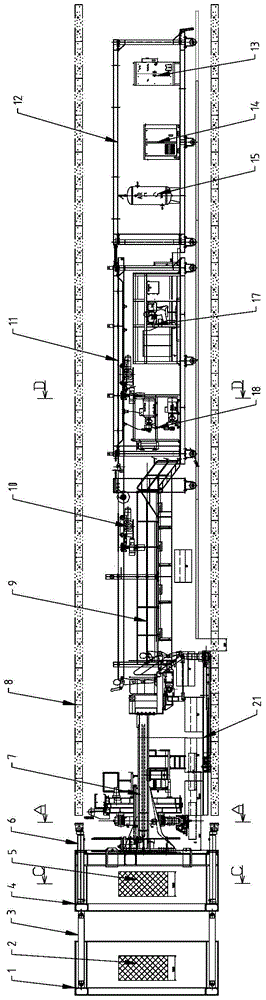

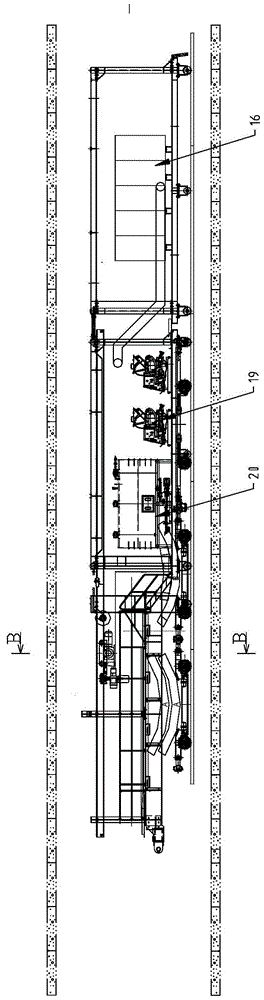

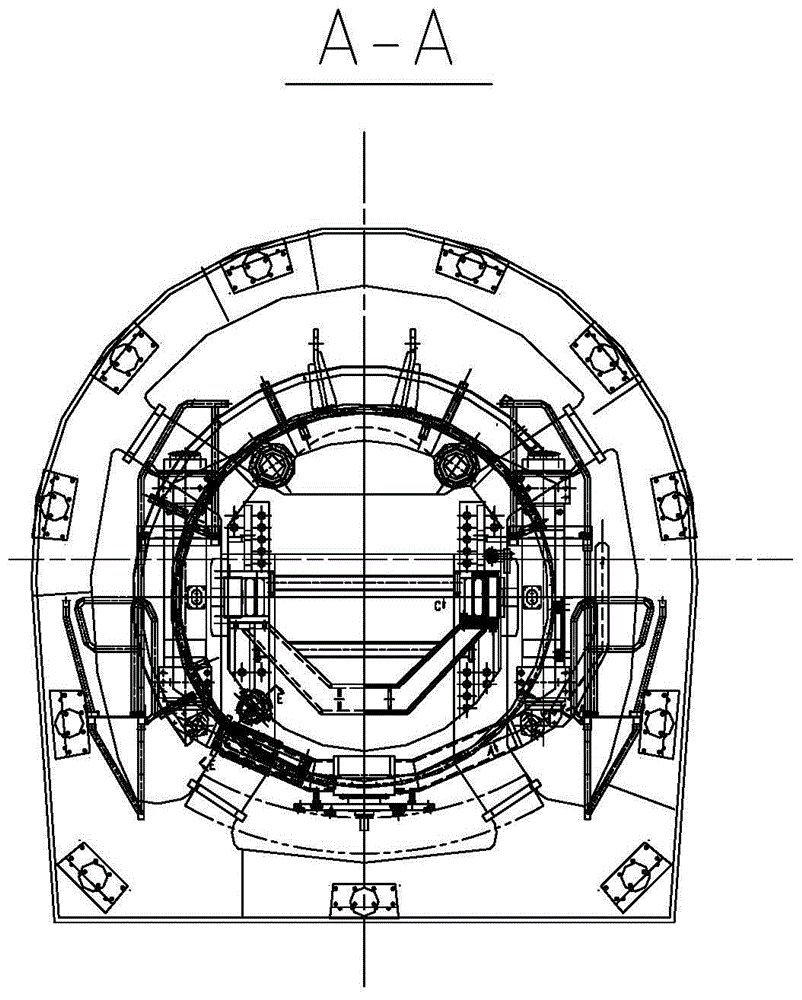

[0028] The present invention will be further described below in conjunction with the drawings.

[0029] Such as Figure 1-6 As shown, this embodiment provides a tunnel segment secondary lining equipment, which includes a supporting device, a segment assembling machine 7, a segment lifting device, a pea gravel injection system, and a double slurry injection system arranged in sequence. The trolley is equipped with hydraulic system, compressed air system and electronic control system on the trolley. The present invention supports and advances through the supporting device. After the segment is hoisted to the segment assembling machine by the segment lifting device, the segment 8 is assembled by the segment assembling machine 7, and the support device moves forward after assembling a complete ring. , During the advancement process, the pea gravel injection system and the double liquid slurry injection system are used to backfill the gaps to ensure the waterproof performance of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com