High-sensitivity vibration isolation platform based on linkage type magnetorheological fluid dampers

A magnetorheological fluid and vibration isolation platform technology, applied in the field of vibration isolation platforms and high-sensitivity vibration isolation platforms, can solve problems such as the failure to achieve vibration isolation effects, achieve good engineering applicability, improve sensitivity, and speed up response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

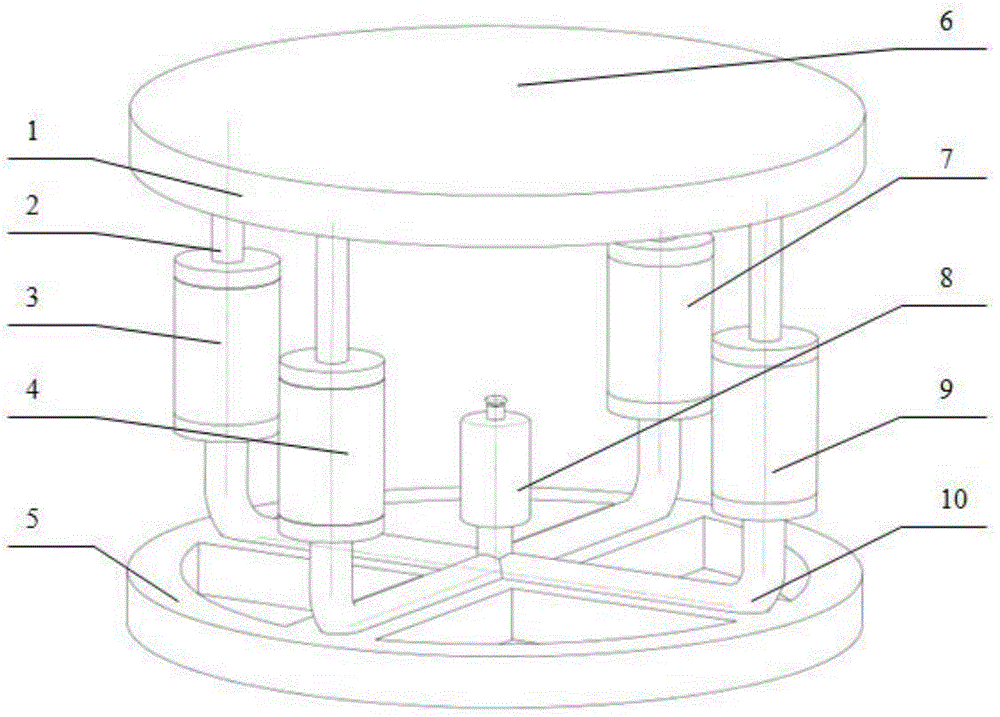

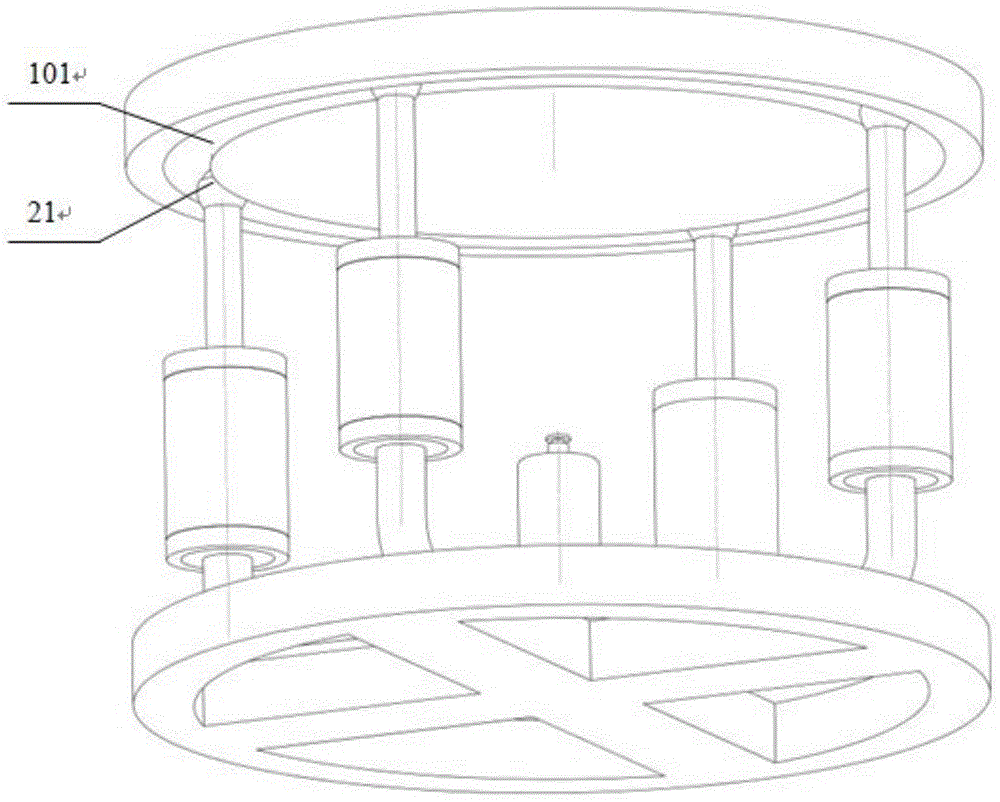

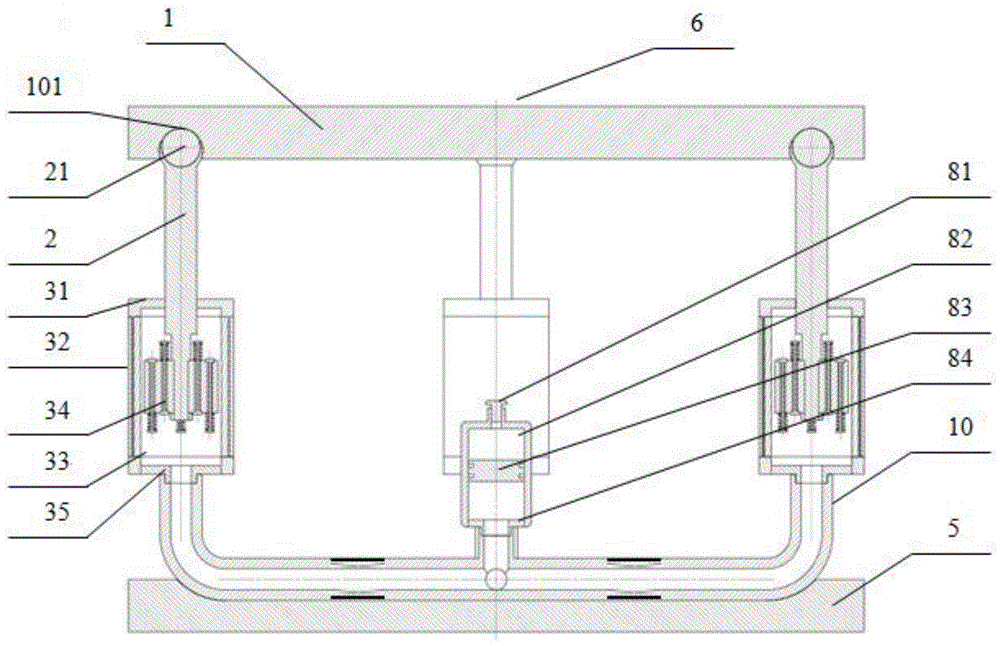

[0042] A high-sensitivity vibration isolation platform based on a connected magneto-rheological fluid damper, such as Figure 1 ~ Figure 3 As shown, it includes a solid platform 5, a moving platform 1, a damper, a communication pipe 10, a piston rod 2 and a compensation cylinder 8, the communication pipe 10 is fixed on the solid platform 5, and the communication pipe 10 is a cross structure, including a centrally located The compensation cylinder interface 105 and four damper interfaces 104 located around it, the compensation cylinder 8 communicates with the compensation cylinder interface 105, and there are four dampers, namely the first damper 3, the second damper 4, and the third damper 9 and the fourth damper 7, the four dampers are respectively connected with the four damper interfaces 104, the lower end of the piston rod 2 is connected in the damper, the upper end is slidingly connected with the moving platform 1, and the upper surface of the moving platform 1 is the obje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com