Pipe robot car with variable-pitch helical crawling ability

A machine car and helical type technology, applied in the direction of pipe components, special pipes, mechanical equipment, etc., can solve the problems of poor steering flexibility and difficult crawling, and achieve the effect of compact structure and high stability

Active Publication Date: 2016-08-10

ZHEJIANG UNIV

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Looking at the current research status of magnetic adsorption wall-climbing robots, most of the existing magnetic crawling robots use magnetic crawlers or permanent magnet blocks to provide magnetic adsorption force, and adopt flat shapes to reduce the center of gravity, such as "Magnetic Adsorption Wall Climbing Robot" (CN104443098A), "A Permanent Magnet Adsorption Wall Climbing Robot" (CN204223014U0), "Magnetic Adsorption Wall Climbing Robot" (CN204223015U), this structure is mainly used in steel planes or curved surfaces with large curvatures. Poor steering flexibility and limited body structure make it difficult to crawl on small curvature surfaces, especially outside pipes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

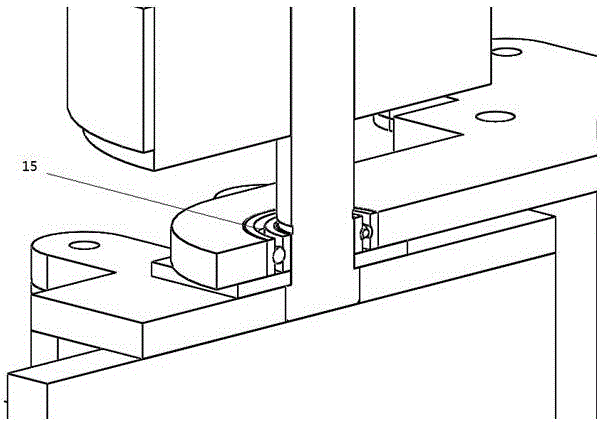

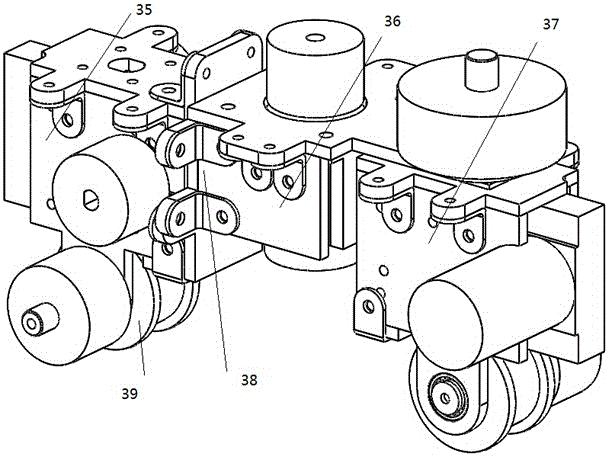

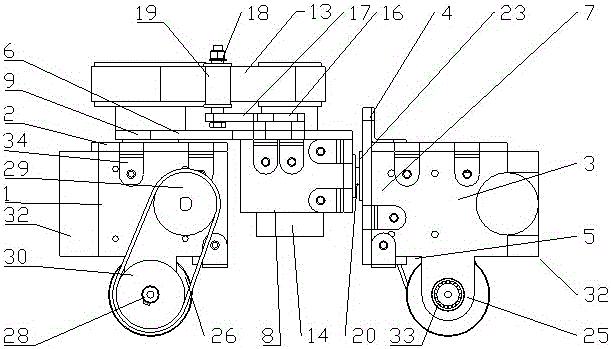

The invention discloses a pipeline robot vehicle with pitch varying spiral line type crawling ability. The pipeline robot vehicle is of a three-section type structure, a front end movement mechanism and a rear end movement mechanism are same in structure and are installed at the front segment and the rear segment of the pipeline robot vehicle respectively, and a movement angle adjustment mechanism is installed in the middle section of the robot vehicle; the front end movement mechanism is connected with the movement angle adjustment mechanism, the movement angle adjustment mechanism is axially connected with the rear end movement mechanism through an axial follow-up structure, and magnetic adsorption wheels used for crawling are installed on the bottoms of the front end movement mechanism and the rear end movement mechanism. The robot vehicle can crawl on the surface of a curved-surface pipeline with various small curvature, welding seams can be adapted, spiral crawling can be achieved, and the robot vehicle can be used for detecting the welding seams of seam-welding pipes; flexible infinite pitch adjustment can be achieved; the structure is compact, and the structure is far smaller than flaw detection equipment generally used at present; aiming at spiral welding pipes with different pitches, the traveling direction of a vehicle body can be adjusted rapidly, and the robot vehicle is attached to the welding seams.

Description

technical field The invention relates to a pipeline robot car, in particular to a pipeline robot car with variable-pitch helical crawling ability, which can be applied to weld seam quality inspection of seam-wrapped pipes. Background technique As a special type of pipe, spiral welded pipe is widely used in modern industry, national defense construction, aerospace and other high-tech industries, as well as people's daily life. Due to the fragility of the weld seam, and the large stress at the weld joint after welding, coupled with the high temperature, high pressure and corrosive working environment, the spiral seam-wound welded pipe is prone to defects such as cracks and perforations at the weld seam , It needs non-destructive testing technology to detect and monitor its working condition and quality. Moreover, with the elevation and undergroundization of pipeline laying and the enlargement of related equipment, it has become increasingly difficult to manually detect pipeli...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16L55/32F16L101/30

CPCF16L55/32F16L2101/30

Inventor 杨克己鲍静涵杨筱钰刘瑞

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com