System and method for assisting in testing of OBD (on-board diagnostics) equipment

A technology for auxiliary testing and equipment, applied in the field of auxiliary testing OBD equipment system, can solve the problems of prolonging the development and testing cycle, lack of OBD equipment, waste of labor costs, etc., to shorten the development and testing cycle, easy to use and maintain, saving The effect of labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

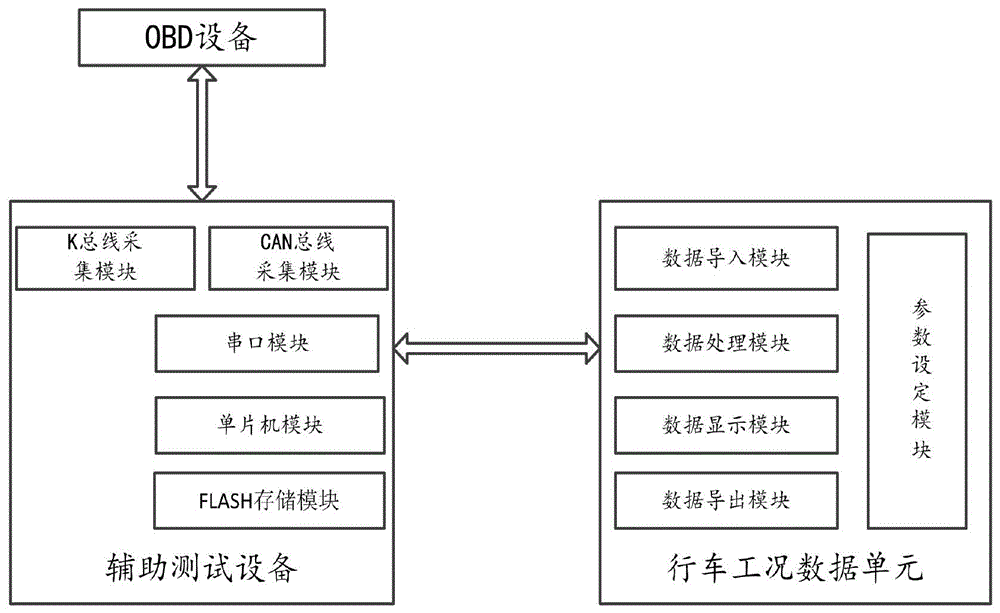

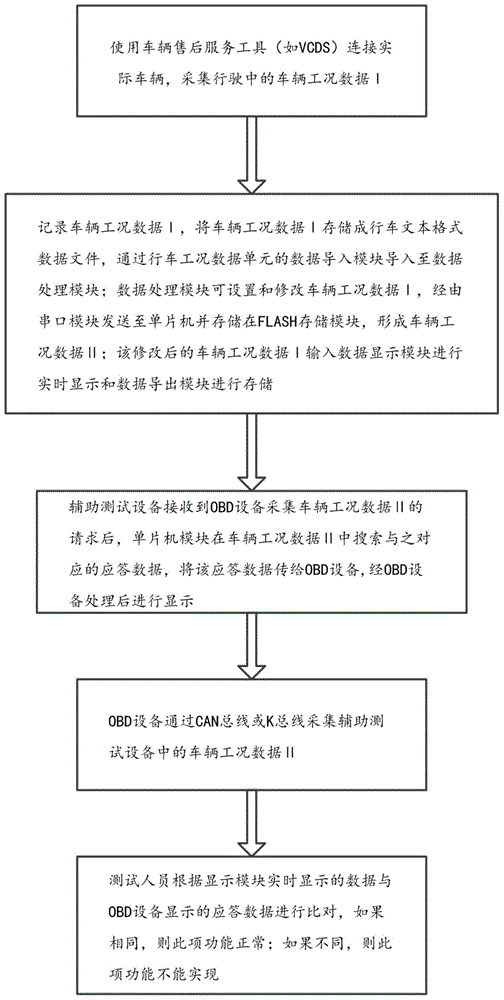

[0031] A system for auxiliary testing OBD equipment, comprising: a driving condition data unit, auxiliary test equipment and OBD equipment; the driving condition data unit is connected with the auxiliary test equipment through a serial port module, and the auxiliary test equipment is also connected through a CAN bus or a K The bus is connected to the OBD device; the driving condition data unit includes: a data import module, a data processing module, a parameter setting module, a data display module and a data export module; the data import module will collect the vehicle condition data I Analyze for use by the data processing module; data processing module, set and modify the vehicle operating condition data Ⅰ provided by the data import module, and supply it to the data display module and data export module; parameter setting module, set the vehicle ignition status and Data update cycle; the data display module displays the modified vehicle operating condition data Ⅰ in real ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com