A device and method for testing metal corrosion fatigue crack growth

A technology for fatigue crack growth and metal corrosion, which is applied in the direction of measuring devices, testing wear resistance, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of errors between measured values and actual values, and achieve extended service life and convenient removal Change, avoid sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

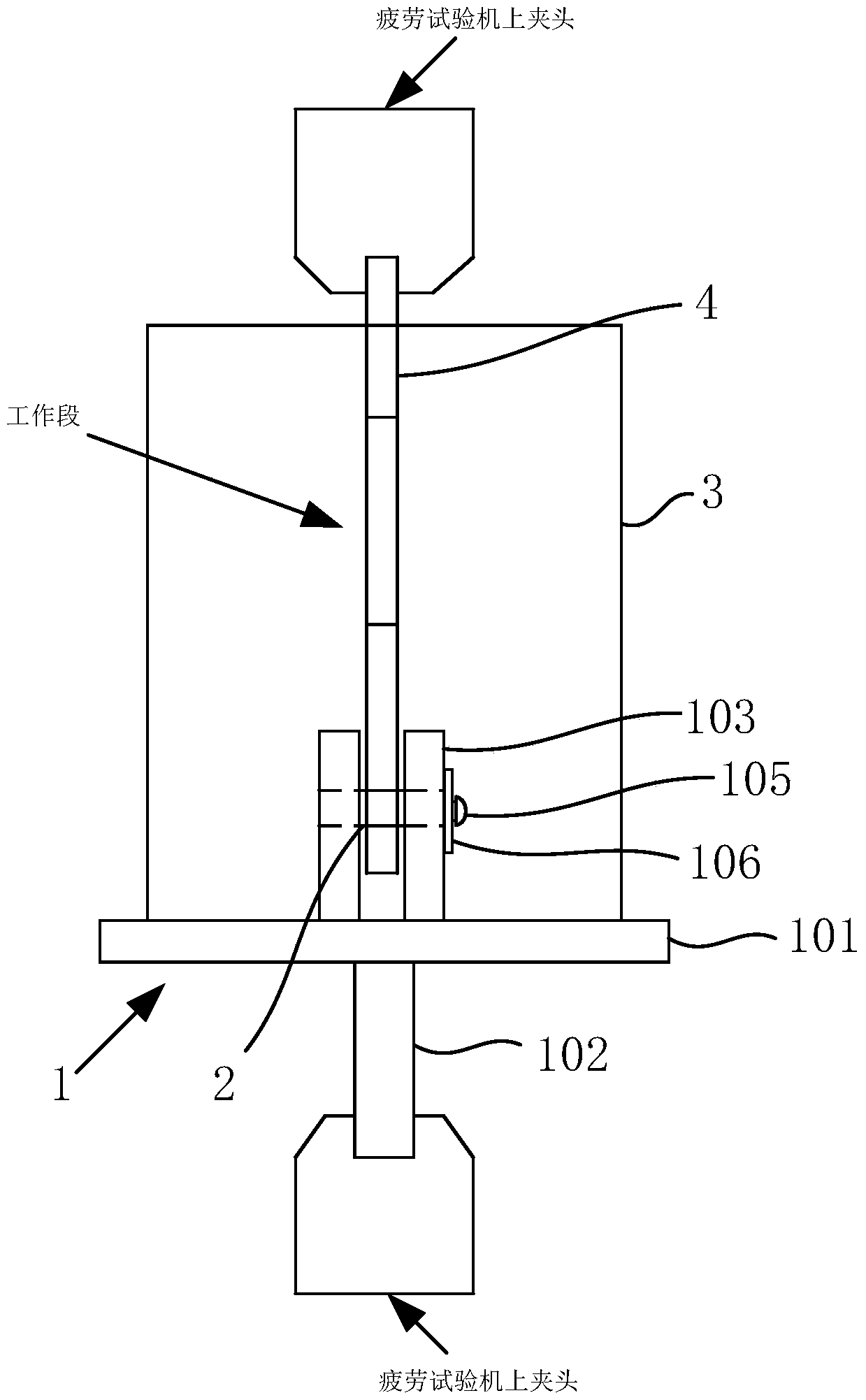

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

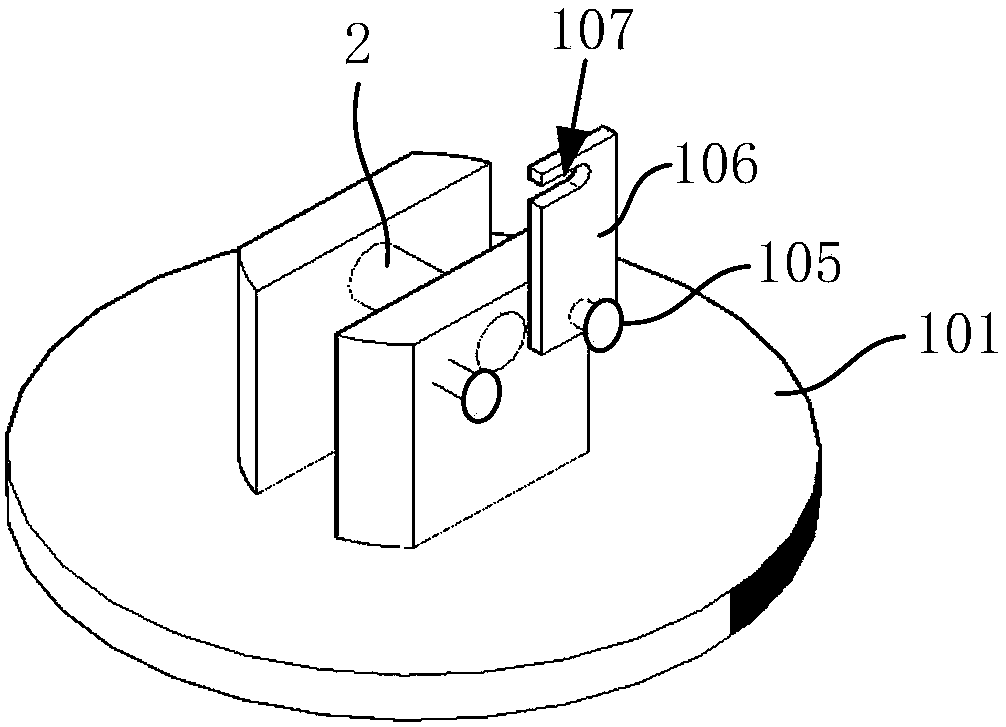

[0034] The device for testing metal corrosion fatigue crack growth in the present invention includes a base 1, a sample positioning part 2 and a corrosive medium container 3, such as figure 1 shown.

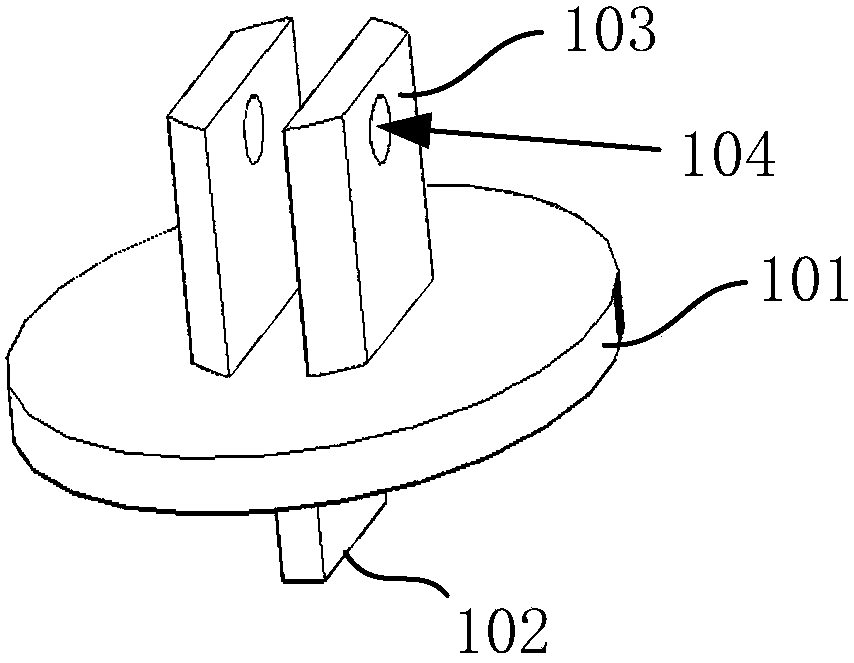

[0035] The base 1 is formed by integral processing of a corrosion-resistant 316L stainless steel cylinder, which can avoid leakage failures due to stress concentration during the test. The base 1 has a circular table top 101, a fatigue testing machine clamping part 102, and a sample locking part 103, such as figure 2 shown.

[0036] Wherein, the clamping part of the fatigue testing machine is arranged at the center of the lower surface of the circular table 101 for clamping the lower chuck of the fatigue testing machine, and after the fatigue testing machine is clamped, the circular table 101 must be in a horizontal state. The sample locking member 103 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com