A kind of porous polyaniline nanocomposite electrode material and its preparation method and application

A nanocomposite and porous structure technology, applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of easy collapse of nanoporous structures, inconspicuous electrochemical stability, complex template removal operations, etc., to achieve Fast electrochemical response, suitable for large-scale production, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

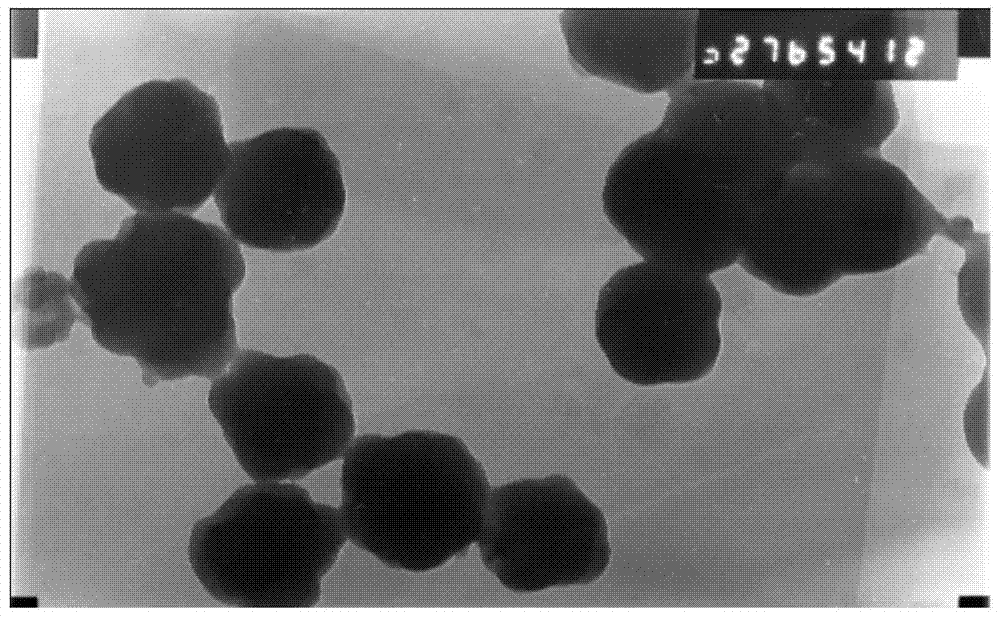

[0040] The preparation of embodiment 1 sulfonated cross-linked polystyrene microspheres

[0041] Dissolve 0.26g of ammonium persulfate in 600mL of deionized water, add 60g of styrene, 4.8g of acrylic acid, and 1.2g of divinylbenzene together under stirring, and react under nitrogen protection at 75°C for 24 hours. Finally, rinse and centrifuge with deionized water and absolute ethanol, filter, and dry to obtain cross-linked polystyrene microspheres, which are denoted as CPS. Take 3 parts by mass of cross-linked polystyrene microspheres, add them into 60 parts by mass of concentrated sulfuric acid, ultrasonically disperse for 10 minutes, and then react with stirring in a constant temperature bath at 40° C. for 2 hours. After the reaction, it was poured into deionized water for dilution, washed several times with absolute ethanol / water with a volume ratio of 1:1, centrifuged, filtered and dried to obtain sulfonated cross-linked polystyrene microspheres, which were designated as ...

Embodiment 2

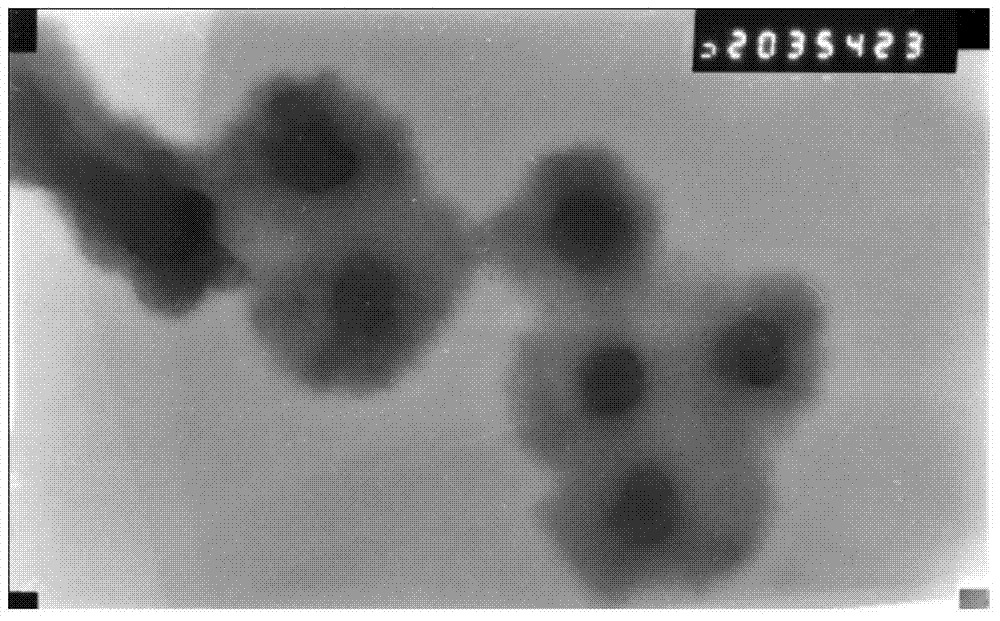

[0042] The preparation of embodiment 2 sulfonated cross-linked polystyrene microspheres

[0043] Dissolve 0.26g of ammonium persulfate in 600mL of deionized water, add 60g of styrene, 4.8g of acrylic acid, and 1.2g of divinylbenzene together under stirring, and react under nitrogen protection at 75°C for 24 hours. Finally, rinse and centrifuge with deionized water and absolute ethanol, filter, and dry to obtain cross-linked polystyrene microspheres, which are denoted as CPS. Take 3 parts by mass of cross-linked polystyrene microspheres, add them into 50 parts by mass of concentrated sulfuric acid, ultrasonically disperse for 10 minutes, and then stir and react in a constant temperature bath at 40° C. for 3 hours. After the reaction, it was poured into deionized water for dilution, washed several times with absolute ethanol / water with a volume ratio of 1:1, centrifuged, filtered and dried to obtain sulfonated cross-linked polystyrene microspheres, which were designated as CSP3....

Embodiment 3

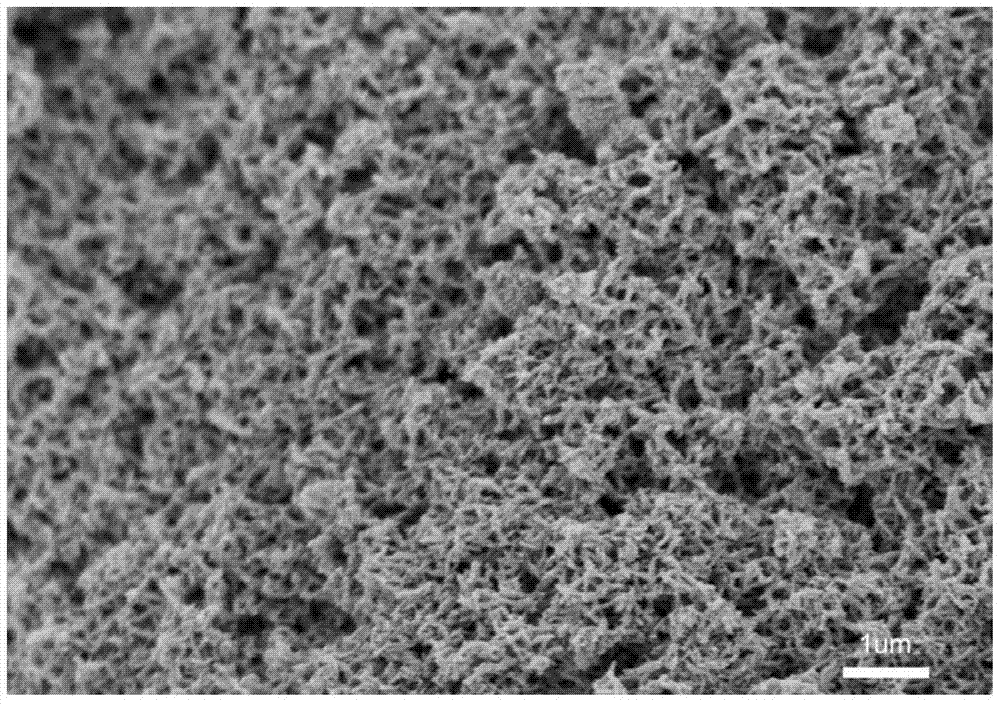

[0044] The preparation of embodiment 3 sulfonated cross-linked polystyrene microspheres

[0045] Dissolve 0.26 g of ammonium persulfate in 600 mL of deionized water, add 60 g of styrene, 4.8 g of acrylic acid, and 1.2 g of divinylbenzene together under stirring, under nitrogen protection, and react with constant stirring at 75°C for 24 hours. Finally, rinse and centrifuge with deionized water and absolute ethanol, filter, and dry to obtain cross-linked polystyrene microspheres, which are denoted as CPS. Take 3 parts by mass of cross-linked polystyrene microspheres, add them into 60 parts by mass of concentrated sulfuric acid, ultrasonically disperse for 10 minutes, and then stir and react in a constant temperature bath at 40° C. for 6 hours. After the reaction, it was poured into deionized water for dilution, washed several times with absolute ethanol / water with a volume ratio of 1:1, centrifuged, filtered and dried to obtain sulfonated cross-linked polystyrene microspheres, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com