Lead mounting device and lead mounting method of concealed and buried wiring pipe

A technology for pipe threading and wire pipe is applied in the field of buried wire pipe threading devices, which can solve the problems of large labor cost consumption, inability to reuse steel wires, waste of steel wires and iron wires, etc., and achieves low input cost and waste. Reusable, easy to bend effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

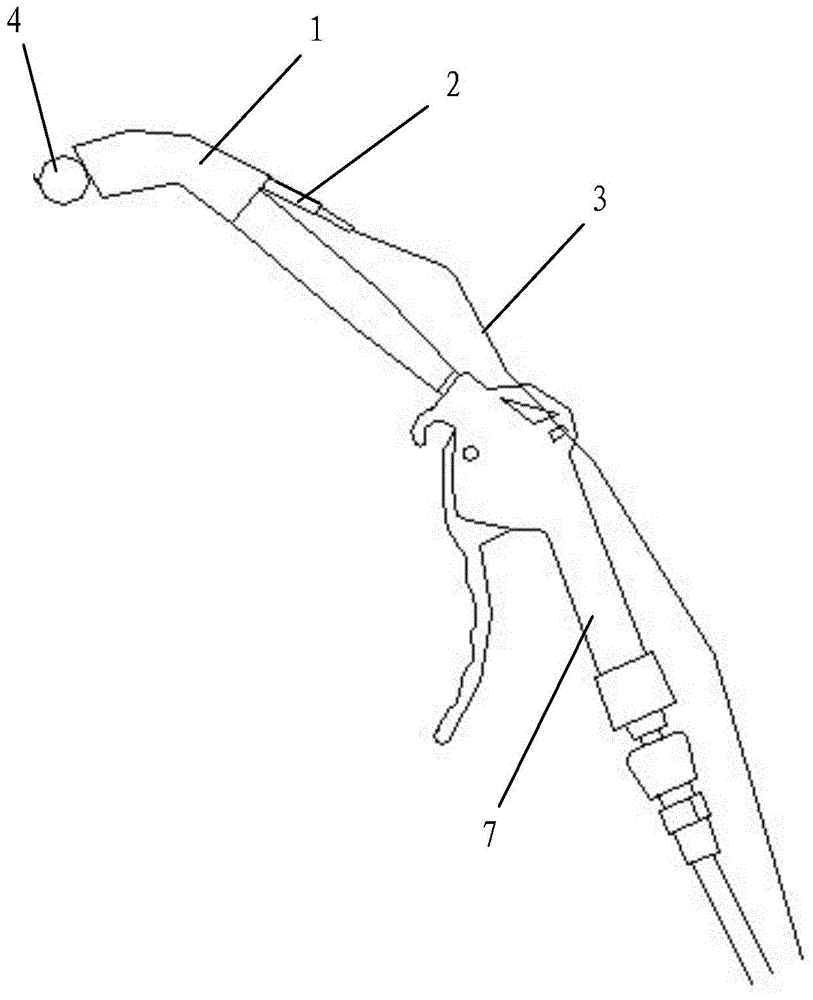

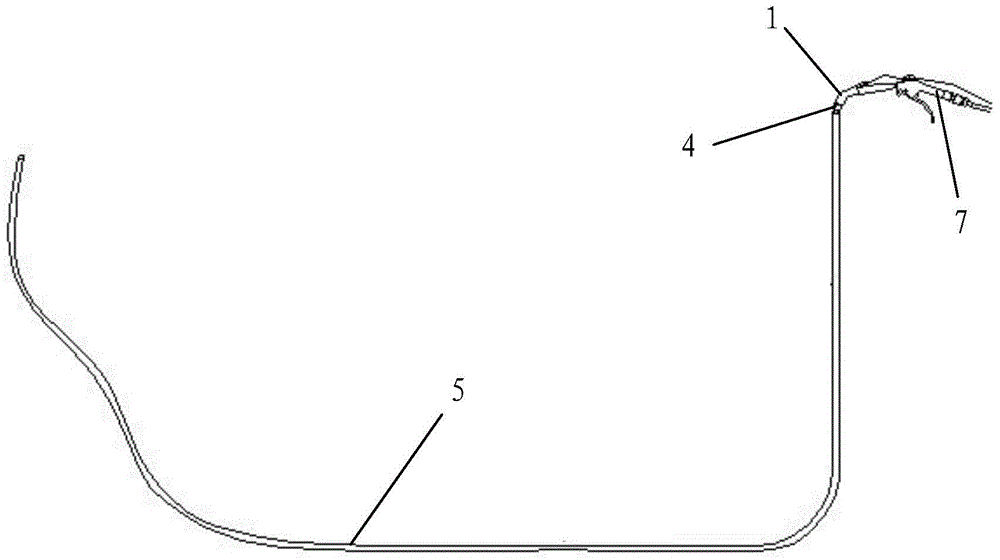

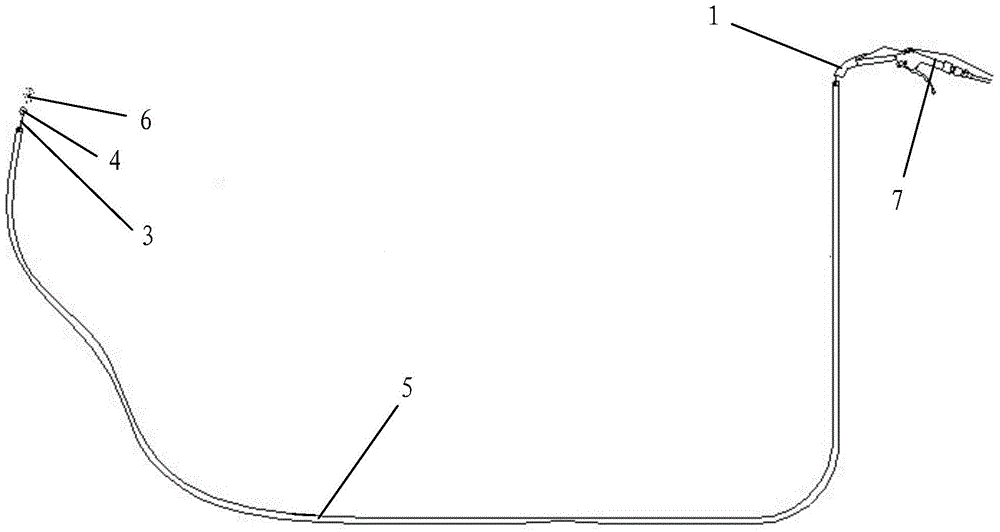

[0041] Such as figure 1 Shown is a concealed wire pipe threading device, including a gun head elbow 1 and a wire guide 2 installed on the gun head elbow 1, the gun head elbow 1 is installed in the air compressor from front to back The elbow on the muzzle of the air gun 7. The front part of the thread guide 2 is inserted into the gun head elbow 1 from back to front. The thread guide 2 has a lead channel for the lead wire 3 to pass through, and the lead channel communicates with the inside of the gun head elbow 1 , The front end of the lead wire 3 passes through the lead channel from back to front and an elastic ball 4 is fixed at its front end, the diameter of the elastic ball 4 is larger than the inner diameter of the buried wire tube 5; 1 is fixed on the muzzle of the air gun 7 with adhesive tape, and the thread guide 2 is fixed between the elbow 1 of the gun head and the muzzle of the air gun 7.

[0042] In this embodiment, the gun tip elbow 1 is an L-shaped elbow.

[0043] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com