Annular stack of laminations comprised of single-tooth stacks and method of manufacturing a stack of lamination

A laminated stack and single-tooth technology, applied in chemical instruments and methods, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve problems such as chip short circuit, and achieve easy assembly, excellent electrical and/or geometric performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

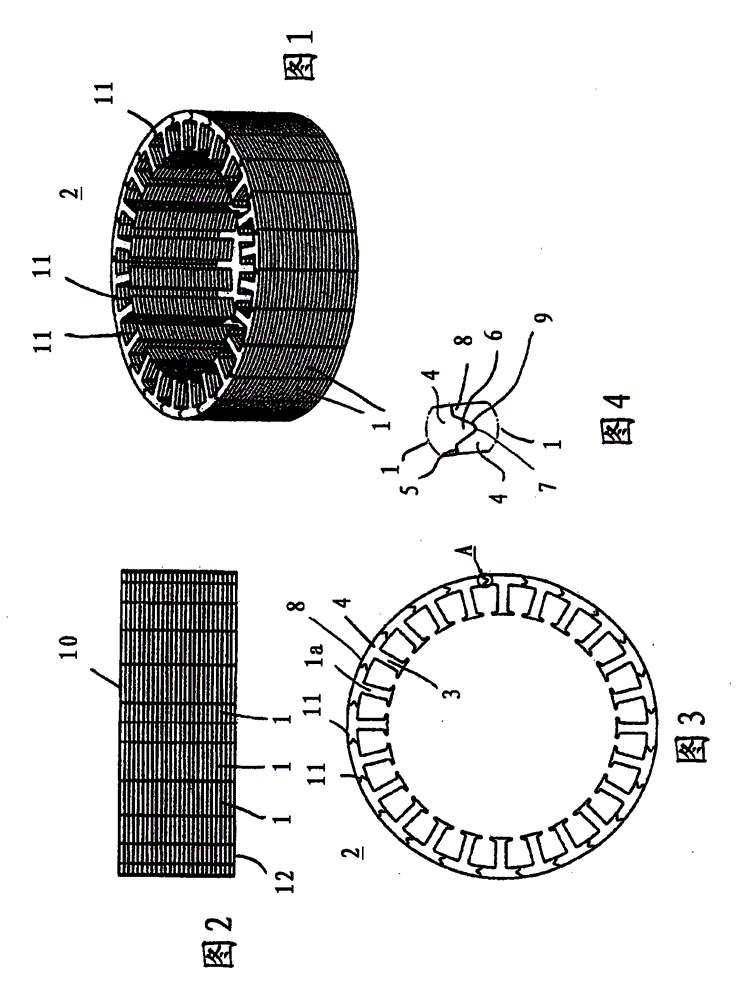

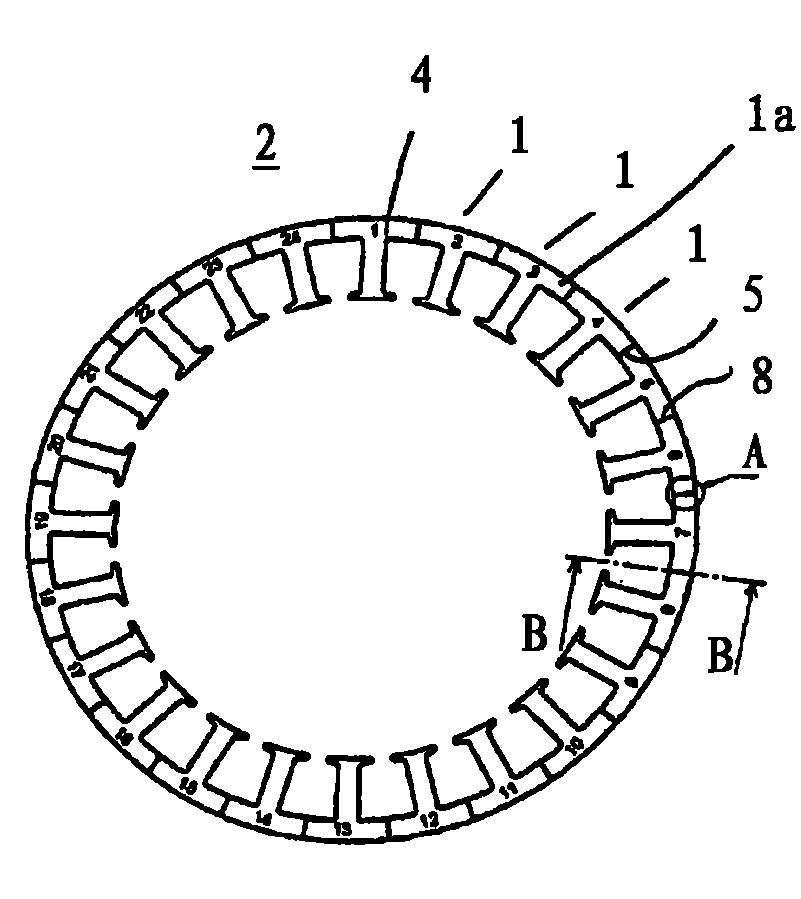

[0032] An annular lamination stack is formed of the single-tooth-shaped laminations described below, and is applied to an electric motor. Lamination stacks of this type are used, for example, in rotors and / or stators of electric motors.

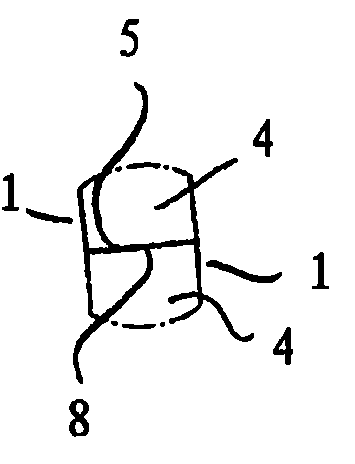

[0033] The laminations described below are single teeth which form a ring. The punched-out rings are then assembled to form an annular lamination stack 2, which consists of a set of single teeth 1 lying against each other. Their reference numbers are, for example, Figure 5 shown. according to Figure 5 In the described embodiment, the annular lamination set 2 consists of 24 single tooth sets 1 . For transport to the user, the single-tooth set 1 is assembled into an annular lamination set 2 . The user separates the annular lamination set 2 into the single tooth set 1 for wrapping and winding. The single tooth set 1 is then reassembled to form the lamination set 2 in the previous sequence. The single-tooth sets 1 are designed so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com