Built-in multi-disc brake permanent magnet motor

A permanent magnet motor, built-in technology, applied in the direction of controlling mechanical energy, electrical components, electromechanical devices, etc., can solve the problems of large diameter of brake flange, limited application of permanent magnet motor, large space, etc., to reduce manufacturing costs and operation. Cost, reduction in size and weight, effect of simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

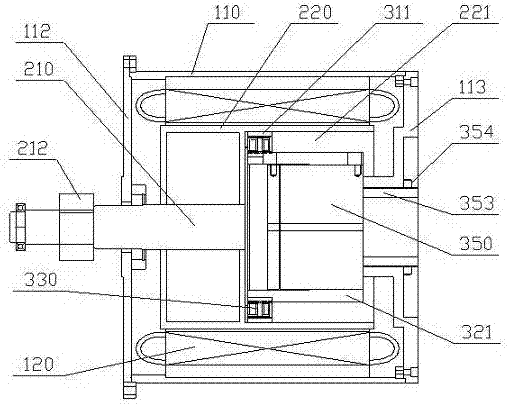

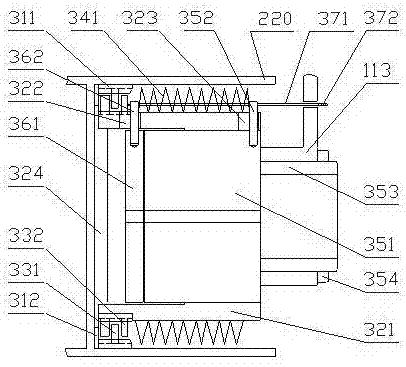

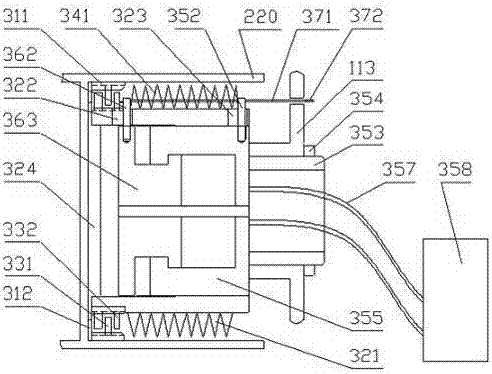

[0009] see Figure 1-3 , The built-in multi-disc brake permanent magnet motor disclosed in the present invention includes a rotor 220, a stator and a built-in brake device, the rotor is located in the stator and is connected to the stator through a bearing for rotation, and the iron core of the stator 120 is installed in the casing 110 of the motor. The casing is provided with a front end cover 112 and a rear end cover 113. The rotating shaft 210 of the rotor faces forward and extends from the shaft hole of the front end cover to form the output of the motor. The shaft is usually equipped with an output gear 212, and the rear part of the rotor is a cylindrical section with an open rear end, which is provided with a cylindrical space 221 capable of accommodating the built-in multi-disc braking device. The moving device includes a rotating cylinder 311, a brake cylinder 321, a brake disc assembly 330, an elastic device and a power device 350. The brake disc 331 and the static b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com