Aluminum alloy conductor, aluminum alloy stranded wire, covered electric wire, wire harness, and manufacturing method of aluminum alloy conductor

A technology of aluminum alloy wire and manufacturing method, applied in the direction of metal/alloy conductor, cable/conductor manufacturing, conductor, etc., can solve the problems of fatigue damage impact resistance, bending fatigue resistance characteristics are not disclosed or implied, and achieve tensile strength High, high impact resistance, the effect of improving impact resistance

Active Publication Date: 2017-12-05

FURUKAWA ELECTRIC CO LTD +1

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, Patent Document 1 describes that it has excellent bending properties because it has sufficient elongation. However, for example, when aluminum alloy wires are used as wire harnesses attached to doors, etc., repetitions occur due to opening and closing of doors. Bending stress, impact resistance and bending fatigue resistance in use environments prone to fatigue damage are not disclosed or implied

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

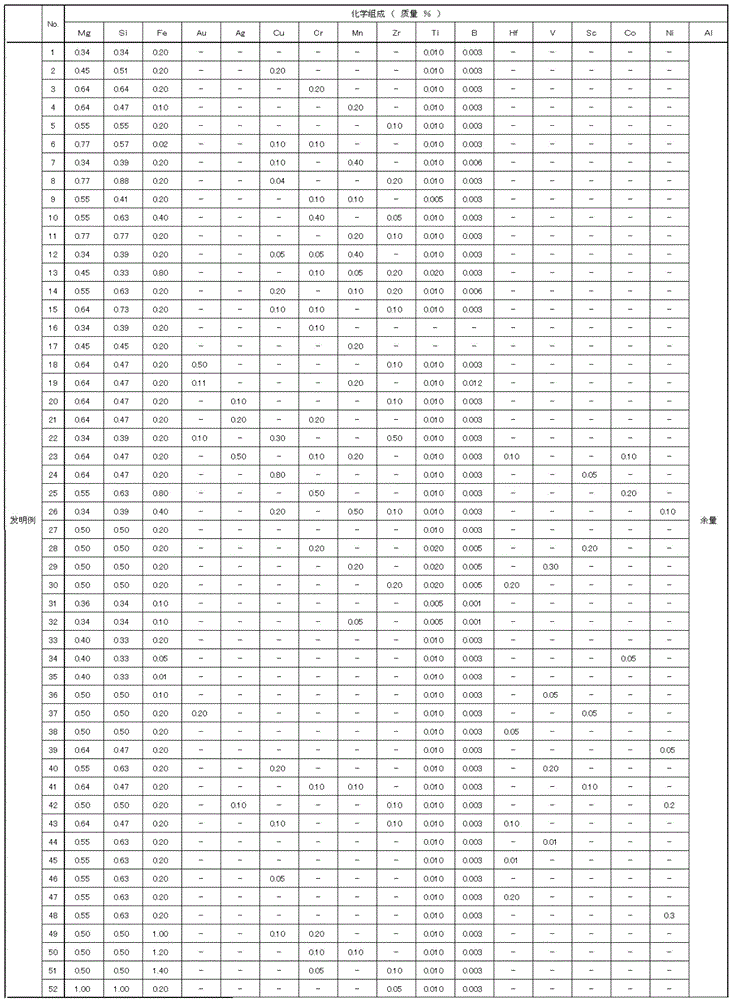

[0101] The present invention will be described in detail based on the following examples. In addition, this invention is not limited to the Example shown below.

[0102] Examples, comparative examples

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

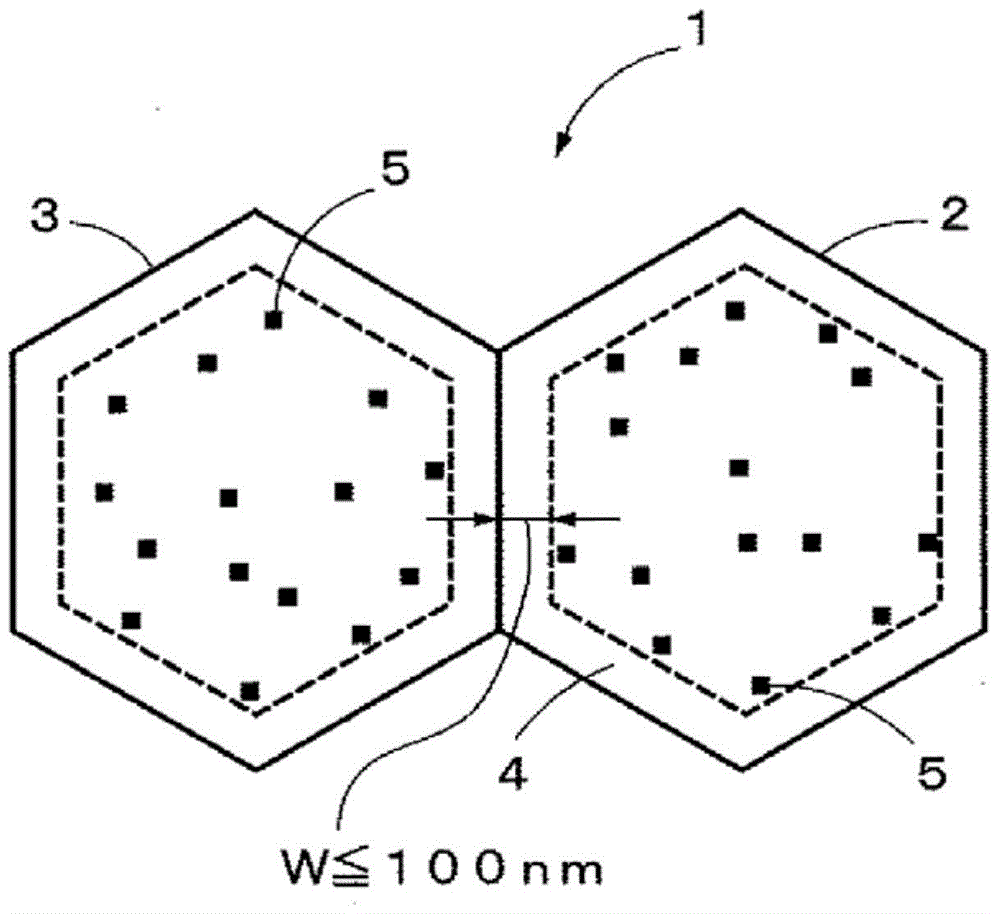

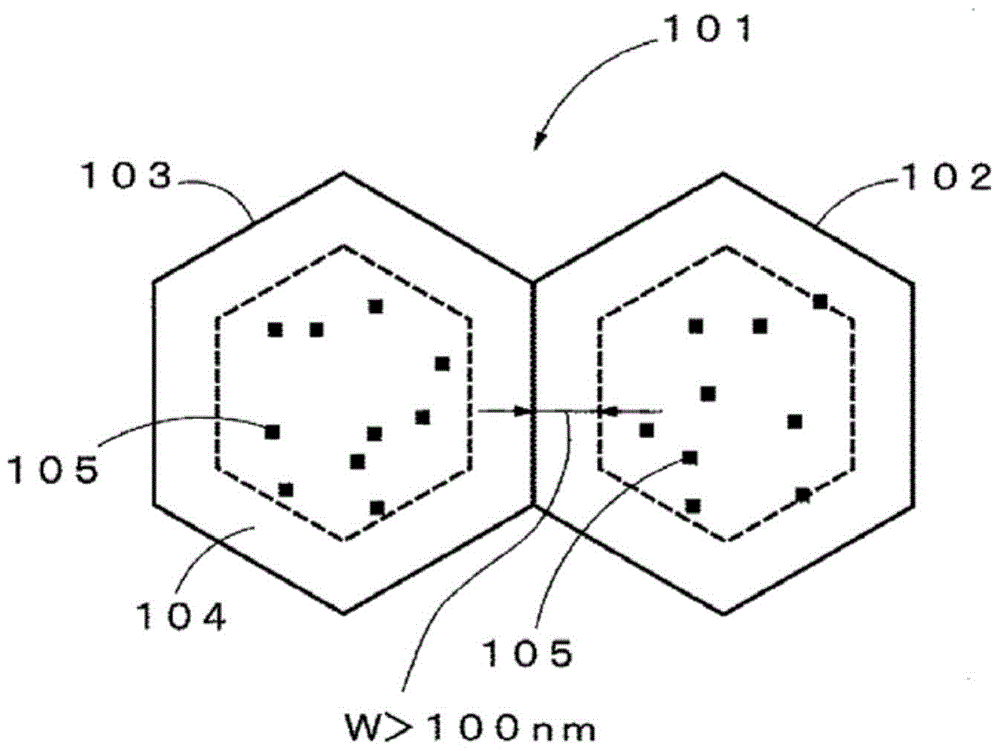

The present invention provides, especially when used as an ultra-thin wire with a bundle diameter of 0.5mm or less, while ensuring strength, elongation, and electrical conductivity at the same level as existing products, and improving impact resistance and bending fatigue resistance. Aluminum alloy conductors used as conductors of electrical wiring bodies, etc. The aluminum alloy conductor of the present invention has the following chemical composition: Mg: 0.10-1.00 mass%, Si: 0.10-1.00 mass%, Fe: 0.01-1.40 mass%, Ti: 0.000-0.100 mass%, B: 0.000-0.030 mass% , Cu: 0.00-1.00 mass%, Ag: 0.00-0.50 mass%, Au: 0.00-0.50 mass%, Mn: 0.00-1.00 mass%, Cr: 0.00-1.00 mass%, Zr: 0.00-0.50 mass%, Hf : 0.00 to 0.50% by mass, V: 0.00 to 0.50% by mass, Sc: 0.00 to 0.50% by mass, Co: 0.00 to 0.50% by mass, Ni: 0.00 to 0.50% by mass, balance: Al and unavoidable impurities, in A precipitation-free zone exists in the crystal grain, and the width of the above-mentioned precipitation-free zone is 100 nm or less.

Description

technical field [0001] The present invention relates to an aluminum alloy conductor used as a conductor of an electric wiring body, an aluminum alloy stranded wire, a covered electric wire, a wire harness, and a method for manufacturing an aluminum alloy wire, and particularly relates to an extremely thin wire having a wire bundle diameter of 0.5 mm or less In this case, it is also possible to ensure the same level of strength, elongation, and electrical conductivity as existing products, and to improve the impact resistance and bending fatigue resistance of the aluminum alloy conductor. Background technique [0002] At present, as electrical wiring bodies of mobile bodies such as automobiles, trains, and airplanes, or electrical wiring bodies of industrial robots, wires made of copper or copper alloy (such as brass) mounted on wires containing copper or copper alloy conductors are used. A component called a wiring harness, which is a terminal (connector). Recently, the hig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C21/00C22F1/04H01B1/02H01B5/02H01B5/08H01B7/00H01B13/00C22F1/00

CPCH01B1/023C22C21/00C22C21/02C22C21/04C22C21/08C22C21/14C22C21/16C22F1/00C22F1/04C22F1/043C22F1/047C22F1/05C22F1/057H01B3/30H01B7/0045

Inventor 关谷茂树吉田祥须齐京太水户濑贤悟

Owner FURUKAWA ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com