Integrated bone cement electric stirring and propelling plant and application thereof

An electric stirring and propulsion device technology, which is applied to mixers with rotary stirring devices, mixer accessories, prostheses, etc., can solve the problems of complex structure, poor mixing uniformity of bone cement, unfavorable saving of operation time, etc., and meets technical requirements The effect of reducing, reducing work intensity and shortening operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

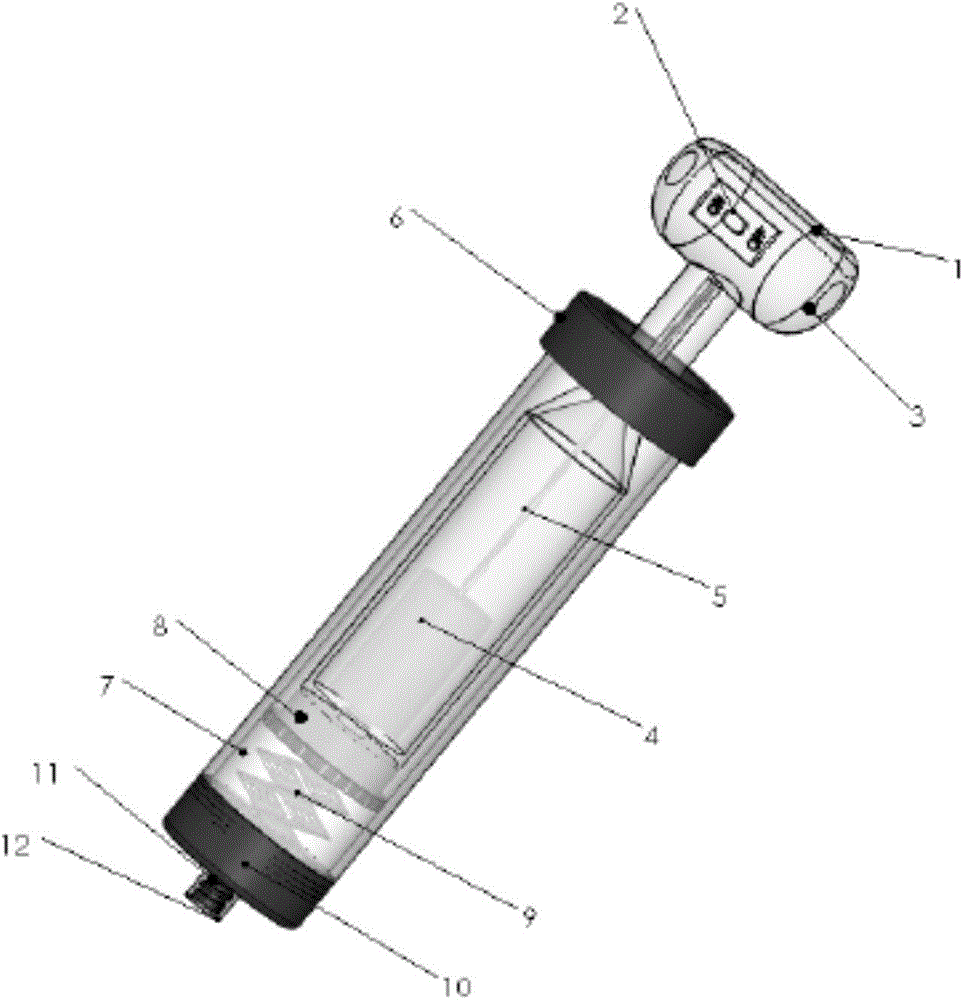

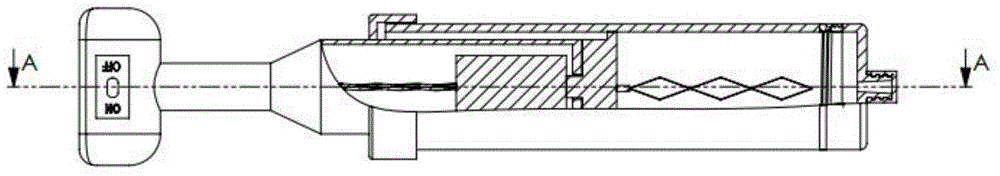

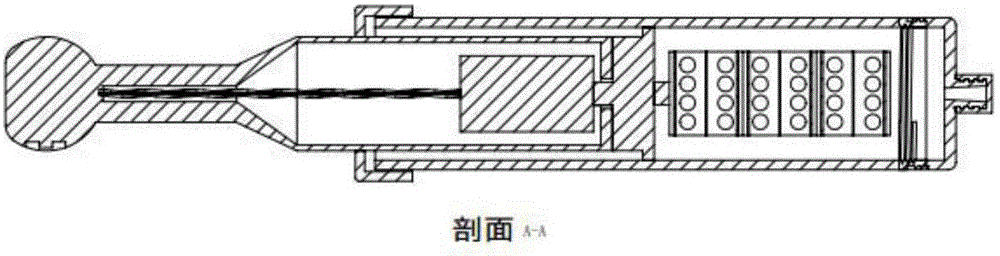

[0033] Please see attached Figure 1-5 , an integrated bone cement electric stirring propulsion device, the stirring device is arranged in the stirring chamber (7), and is composed of foldable blades (9); the rear end of the stirring chamber is provided with a rear end cover (6), and the other end is provided with The front end cover (10) is connected with a luer interface (11) on the front end cover, and a front cap (12) is provided on the luer interface.

[0034] Described miniature electric motor links to each other with control box (3) and switch (2) by electric wire (5),

[0035] The foldable leaves are provided with holes.

[0036] The handle is in the shape of a "T" and consists of two parts, the handle at the near end and the push rod at the far end. The two parts are connected by threads. The control device and power supply are placed in the handle at the near end. Components such as micro motors are placed in the far-end push rod.

[0037] The stirring device is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com