Combined type column floating selection system

A combined flotation column technology, which is applied in the field of flotation systems and combined column flotation systems, can solve problems such as not so obvious advantages, and achieve the effect of simple structure, good reliability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

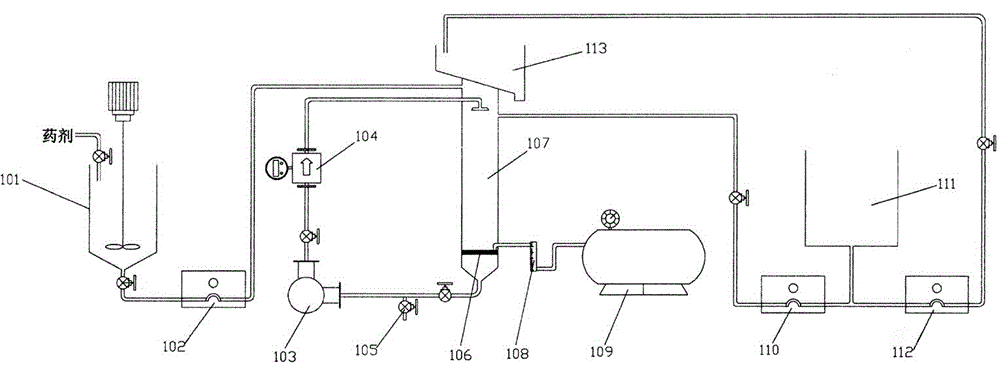

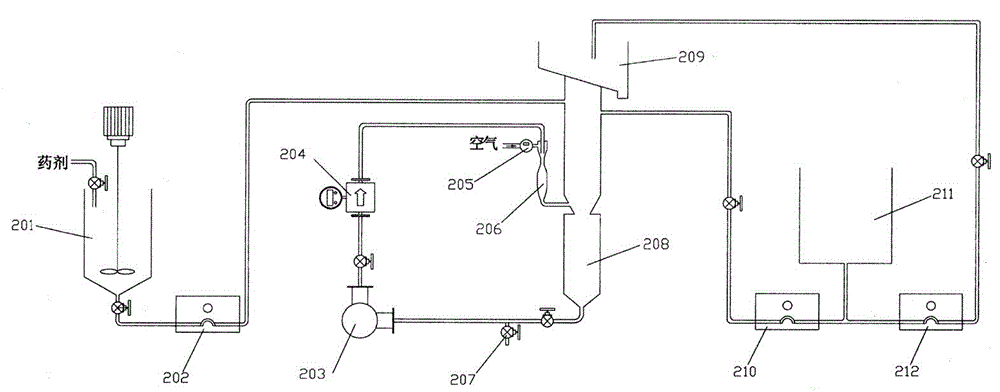

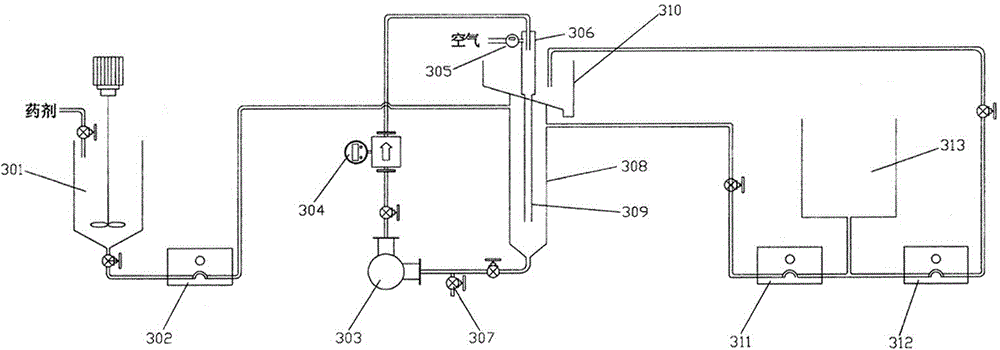

[0028] like figure 1 , 2 , 3, the present embodiment is three kinds of mineralization mode parallel flotation implementation mode, including using countercurrent, swirling flow and jet flow three kinds of mineralization modes in combination in parallel mode, three kinds of mineralization modes are all based on flotation column Core construction, equipped with slurry mixing equipment, chemical system, feed pump, medium ore circulation pump, foam flushing water pump, liquid level control pump, liquid flow meter, gas flow meter; unit flotation is used when the three mineralization methods are used in parallel method.

[0029]The underflow pipe of the slurry mixing equipment 101 in the countercurrent mineralization system is connected to the feed port of the countercurrent flotation column 107 through a valve and a feed pump 102, and the underflow pipe of the countercurrent flotation column 107 passes through a valve, a middling ore circulation pump 103, The liquid flow meter 10...

Embodiment 2

[0038] In this embodiment, two or three mineralization methods can be selected in series to arrange and combine for testing. Since there are many test schemes, the combination of countercurrent + swirl + jet will be used as an example to illustrate the combination structure and test method of the experimental system, such as Figure 4 shown.

[0039] The structure of the test system is as follows:

[0040] The combined system is constructed with the flotation column as the core, equipped with slurry mixing equipment, chemical system, feed pump, medium ore circulation pump, foam flushing water pump, liquid level control pump, liquid flow meter, gas flow meter; three kinds of mineralization The continuous flotation method is adopted when the method is combined in series; it includes the first pulping equipment 1, the first feeding pump 1-1, the first liquid flow meter 1-2, and the countercurrent flotation column 1- 3. The first tailings pump 1-6, the second slurry mixing equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com