Liquid pressure nozzle

A liquid pressure and nozzle technology, applied in the field of internal components, can solve the problems that the liquid pressure nozzle cannot be mixed and distributed with the alkylation reactor, the mixing depth is not enough, and it is prone to failure, so as to avoid unplanned shutdown and high reaction efficiency , the effect that is not easy to fail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

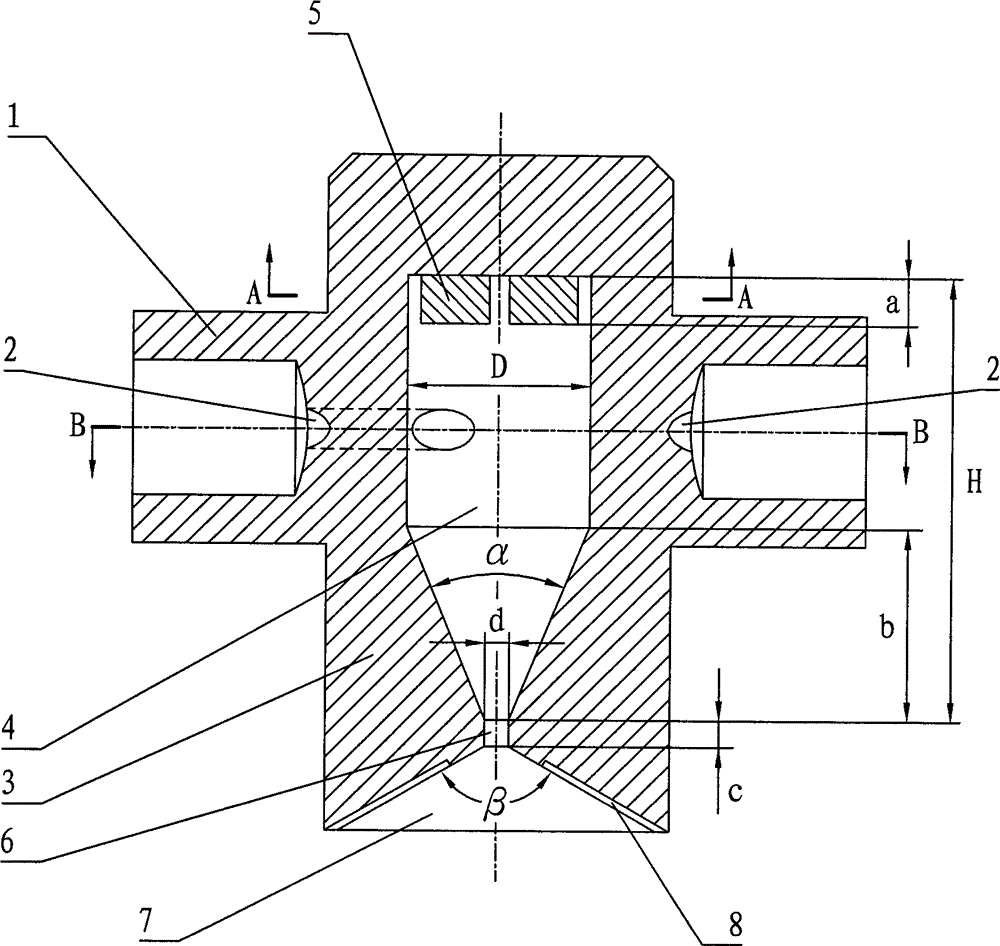

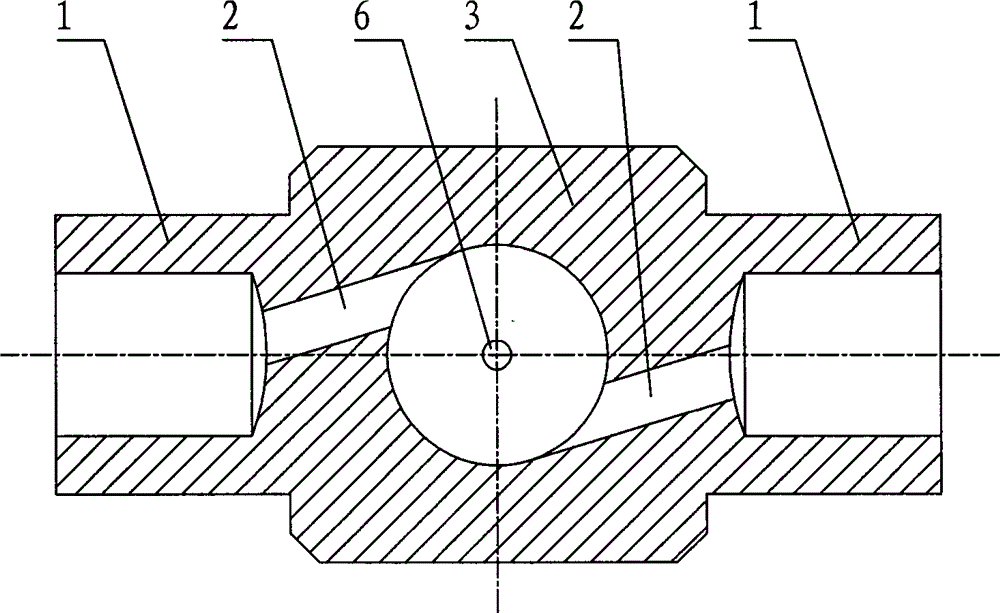

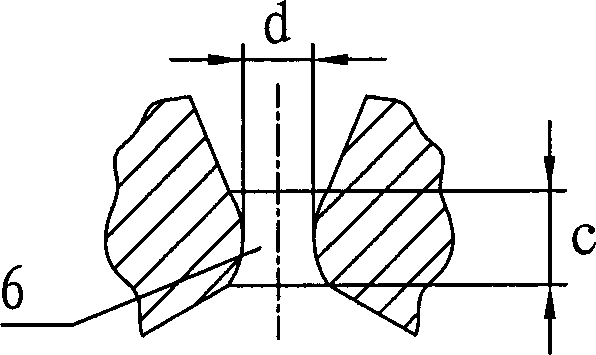

[0017] see figure 1 , figure 2 , a liquid pressure nozzle of the present invention is provided with a main pipe 3, the main pipe 3 is provided with a main pipe lumen 4, and the outlet end of the bottom of the main pipe 3 is provided with a conical nozzle outlet 7. The lumen 4 of the main body tube is composed of an upper cylindrical lumen and a lower inverted conical lumen. The liquid pressure nozzle is provided with two inlet pipes 1, and the two inlet pipes 1 are respectively arranged on opposite sides of the main body pipe 3. The outlet end of each inlet pipe 1 is provided with an inlet pipe inner hole 2, and the inlet pipe inner hole 2 communicates with the cylindrical inner cavity along the tangential direction of the cylindrical inner cavity, and the outlets of the two inlet tube inner holes 2 are respectively located on the side of the cylindrical inner cavity opposite sides. The top end of the cylindrical inner cavity is closed and a spoiler 5 is provided, and a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com