Air-screen specific gravity separator

A cleaning machine and specific gravity technology, which is applied in the field of cleaning machines, can solve the problems of affecting the specific gravity screening effect, poor balance, unstable vibration, etc., and achieve the effect of enhancing the specific gravity selection effect, improving stability and reducing electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

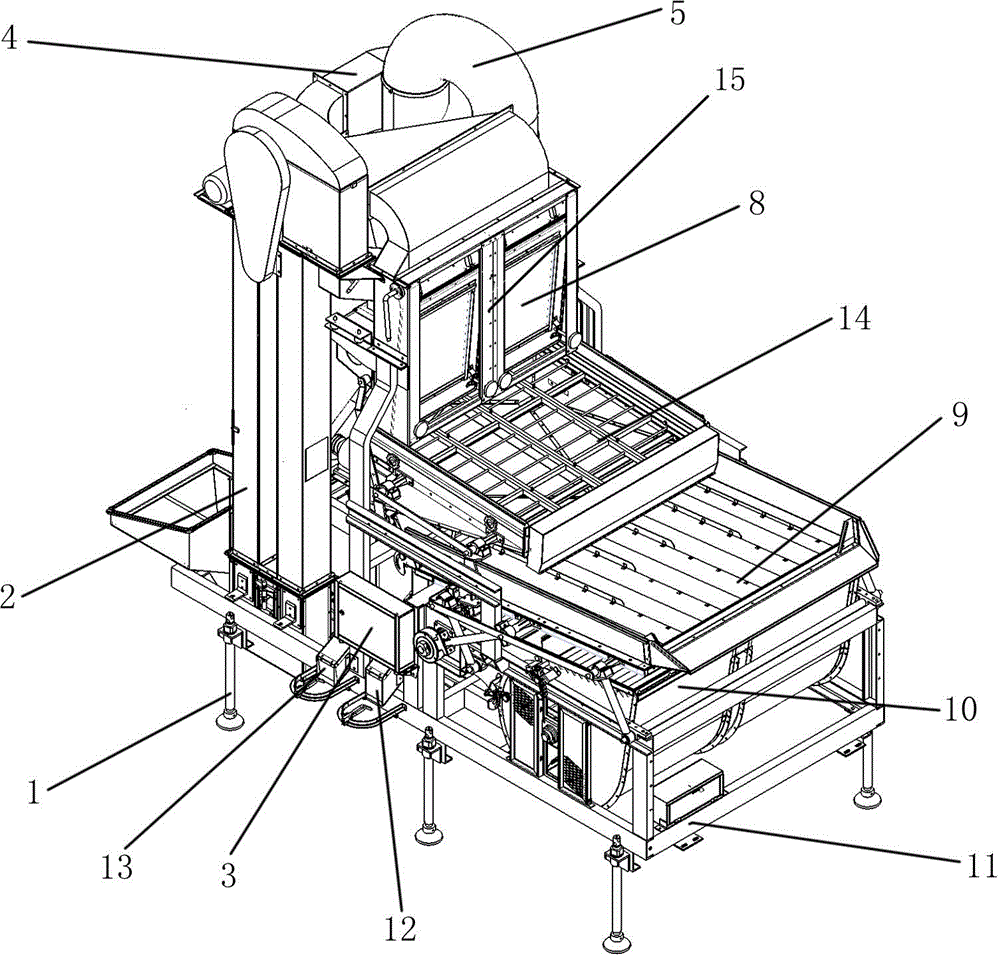

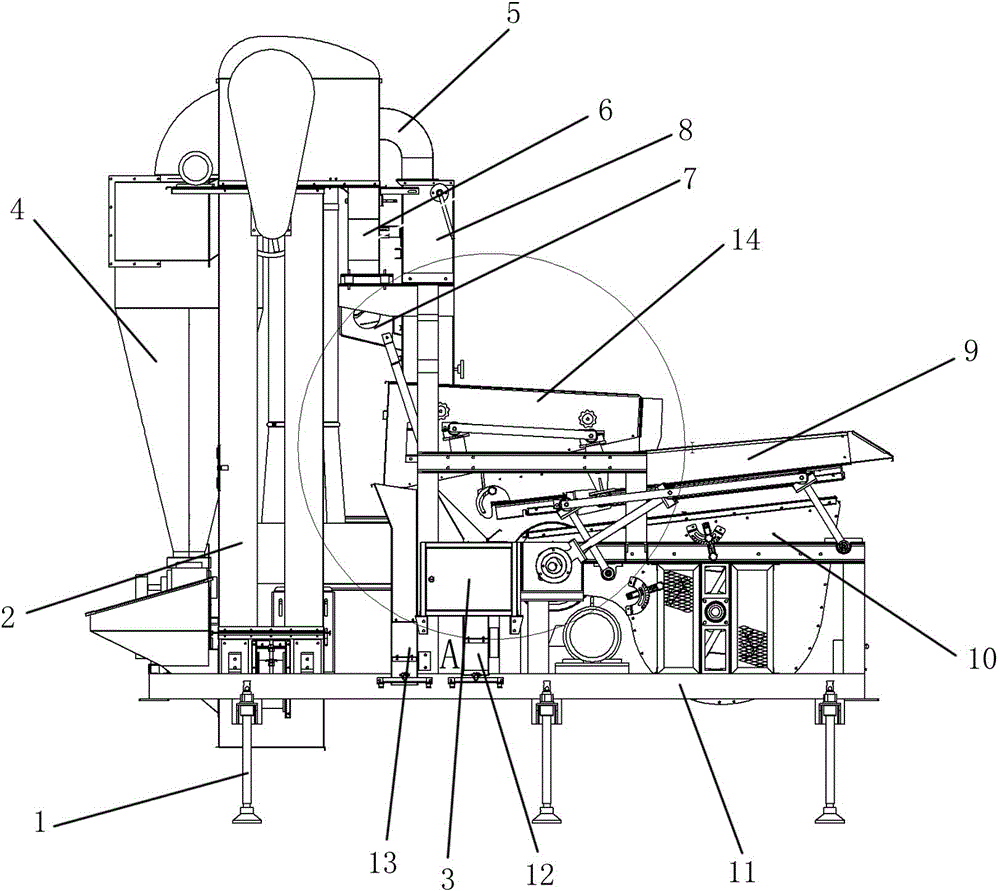

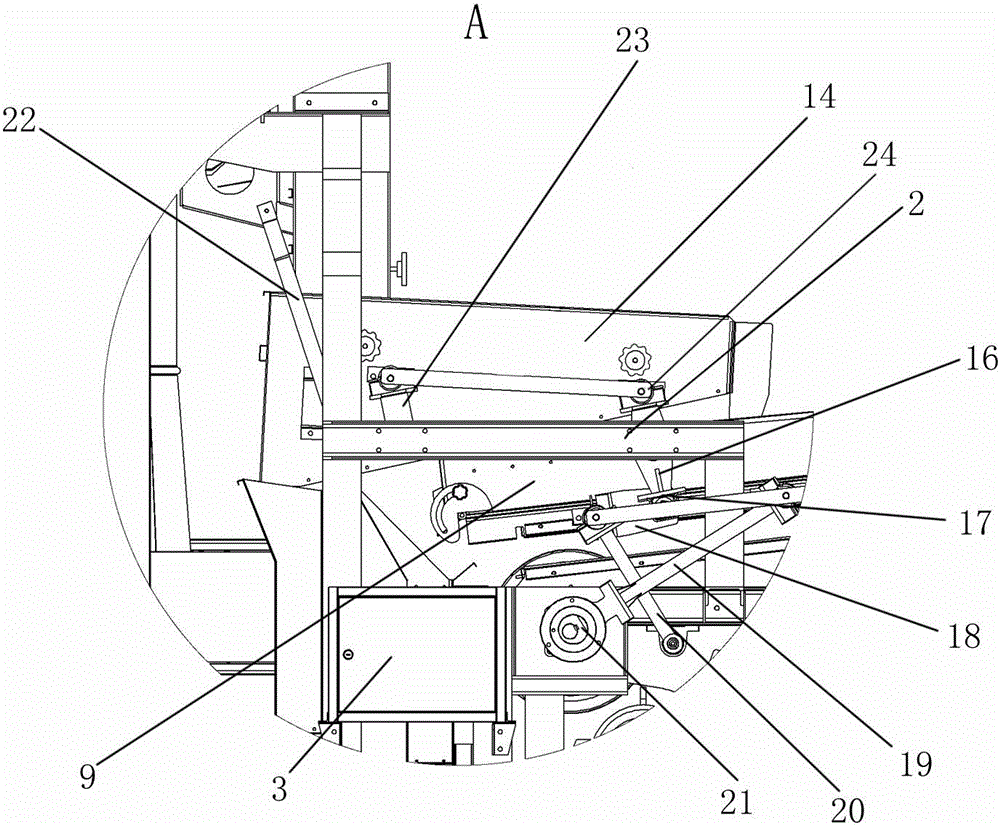

[0020] as attached Figure 1-4 As shown, the present invention includes: a frame 11, a support rod 1 fixedly connected with the frame 11, a hoist 2 arranged on the frame 11, a vertical air screen 8 connected with the feeding pipe 6 of the hoist 2 , the dust removal system 4 that is connected with the vertical air screen 8 through the curved air pipe 5, the specific gravity screening device arranged under the vertical air screen 8 and the distribution box 3 arranged on the frame 11; the specific gravity screening device includes : the specific gravity table 9 arranged under the vertical air screen 8, the fan 10 arranged under the specific gravity table 9 and the light miscellaneous outlet 12 connected with the specific gravity table 9; it is characterized in that: the vertical air screen 8 and the The first half sieve 14, the front half sieve transmission device connecting the front half sieve 14 and the specific gravity screening device and the front half sieve small miscellan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com