Detachment method of offshore platform propeller

An offshore platform and propeller technology, which is applied to ship parts, ships, transportation and packaging, etc., can solve the problems of high cost, long operation time, and large impact of propellers, and achieves simple operation, short time, and low sea condition requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

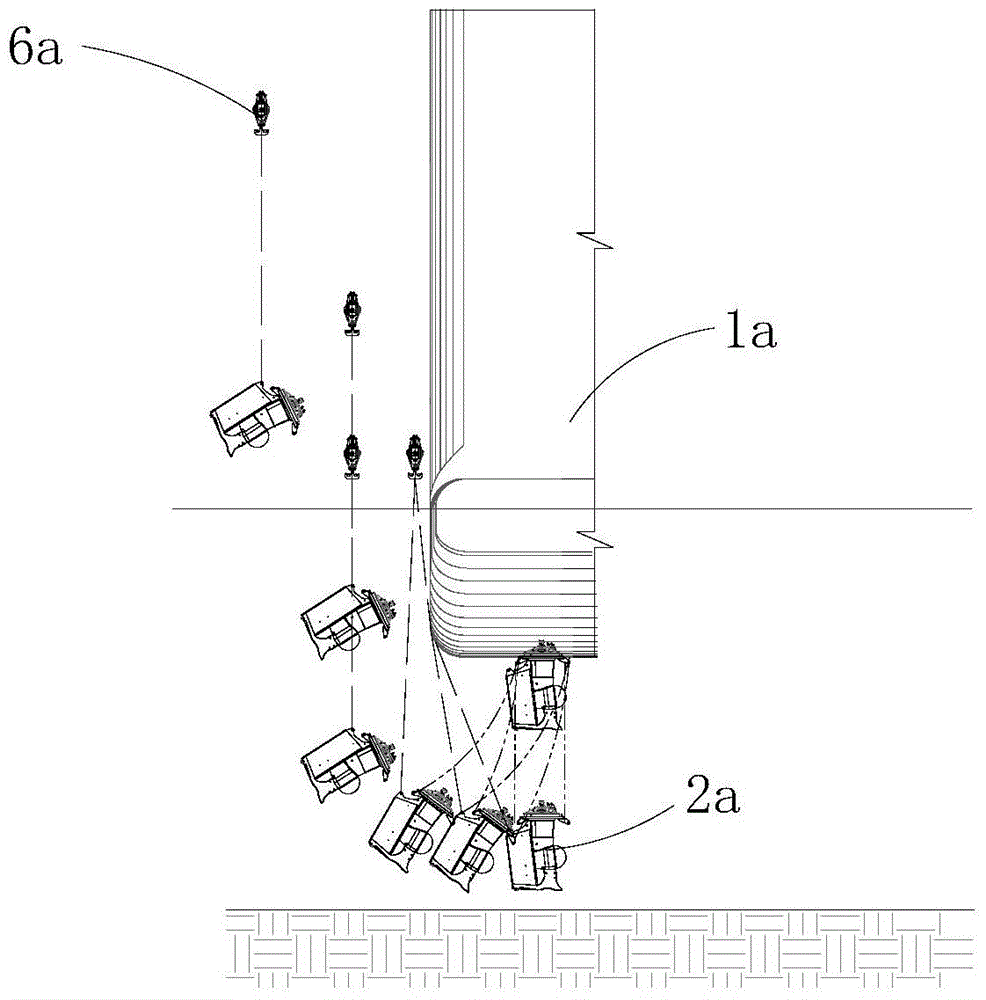

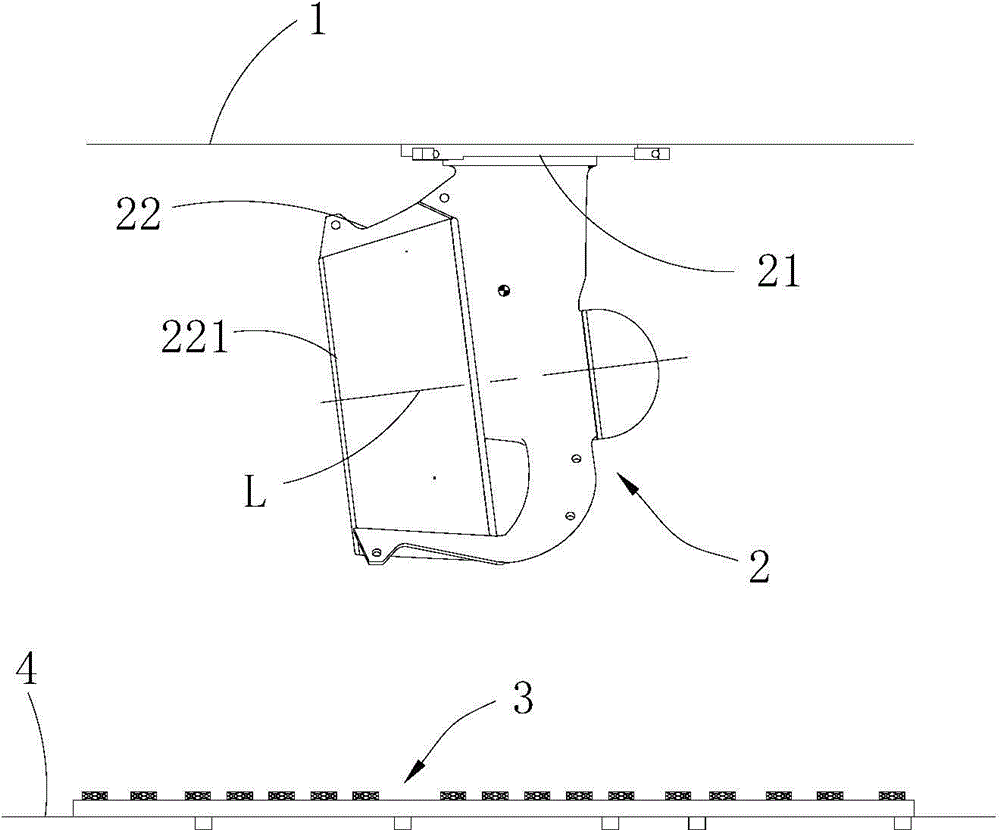

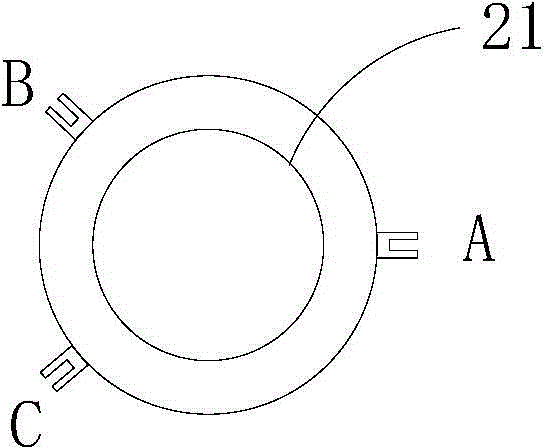

[0044] The invention provides a method for disassembling a thruster of an ocean platform. see first figure 2 , the top of the propeller 2 is provided with a mount 21 for connecting with the offshore platform 1, and the lower part of the propeller 2 is provided with a substantially cylindrical shroud 22, and the open end 221 of the shroud 22 is located on the propeller 2. Side: when the propeller 2 is installed on the ocean platform 1, the propeller 2 is in a vertical state, and the axis L of the fairing 22 is parallel to the horizontal plane or at a sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com