Novel rodent-resistant optical cable and manufacturing process thereof

A manufacturing process and optical cable technology, applied in the field of new anti-rat optical cable and its manufacturing process, can solve the problems of construction difficulties, health impact of operators, high cost of armoring materials, etc., achieve simple optical cable structure and processing technology, and reduce optical cable communication failures , the effect of meeting the environmental application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

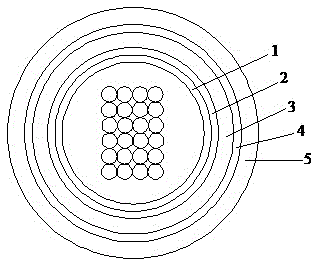

[0027] A new anti-rat optical cable, which is composed of an optical cable core 1, a steel-plastic composite tape 2, an inner sheath protective layer 3, a glass fiber reinforced tape 4 and an outer sheath protective layer 5, and the optical cable core 1 is covered with There is a steel-plastic composite tape 2, the steel-plastic composite tape 2 is extruded with an inner sheath protective layer 3, and the inner sheath protective layer 3 is covered with a glass fiber reinforced tape 4, and the glass fiber The reinforcement band 4 is extruded with an outer sheath protection layer 5 .

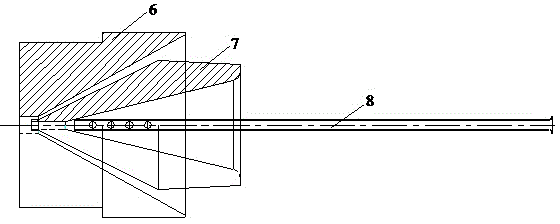

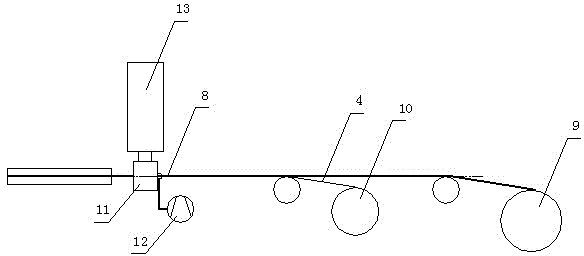

[0028] The manufacturing process of the novel anti-rat optical cable specifically comprises the following steps:

[0029] (1) The steel-plastic composite tape 2 is used to fully cover the optical cable core 1 in a longitudinal wrapping manner outside the optical cable core 1, and the optical cable core 1 is a central tube structure;

[0030] (2) Extrude the inner sheath protection layer 3 outside...

Embodiment 2

[0034] A new anti-rat optical cable, which is composed of an optical cable core 1, a steel-plastic composite tape 2, an inner sheath protective layer 3, a glass fiber reinforced tape 4 and an outer sheath protective layer 5, and the optical cable core 1 is covered with There is a steel-plastic composite tape 2, the steel-plastic composite tape 2 is extruded with an inner sheath protective layer 3, and the inner sheath protective layer 3 is covered with a glass fiber reinforced tape 4, and the glass fiber The reinforcement band 4 is extruded with an outer sheath protection layer 5 .

[0035] The manufacturing process of the novel anti-rat optical cable specifically comprises the following steps:

[0036] (1) The steel-plastic composite tape 2 is used to fully cover the optical cable core 1 in a longitudinal wrapping manner outside the optical cable core 1, and the optical cable core 1 is a layer-twisted structure;

[0037] (2) Extrude the inner sheath protection layer 3 outsid...

Embodiment 3

[0041] A new anti-rat optical cable, which is composed of an optical cable core 1, a steel-plastic composite tape 2, an inner sheath protective layer 3, a glass fiber reinforced tape 4 and an outer sheath protective layer 5, and the optical cable core 1 is covered with There is a steel-plastic composite tape 2, the steel-plastic composite tape 2 is extruded with an inner sheath protective layer 3, and the inner sheath protective layer 3 is covered with a glass fiber reinforced tape 4, and the glass fiber The reinforcement band 4 is extruded with an outer sheath protection layer 5 .

[0042] The manufacturing process of the novel anti-rat optical cable specifically comprises the following steps:

[0043] (1) The steel-plastic composite tape 2 is used to fully cover the optical cable core 1 in a longitudinal wrapping manner outside the optical cable core 1, and the optical cable core 1 is a central tube structure;

[0044] (2) Extrude the inner sheath protection layer 3 outside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com