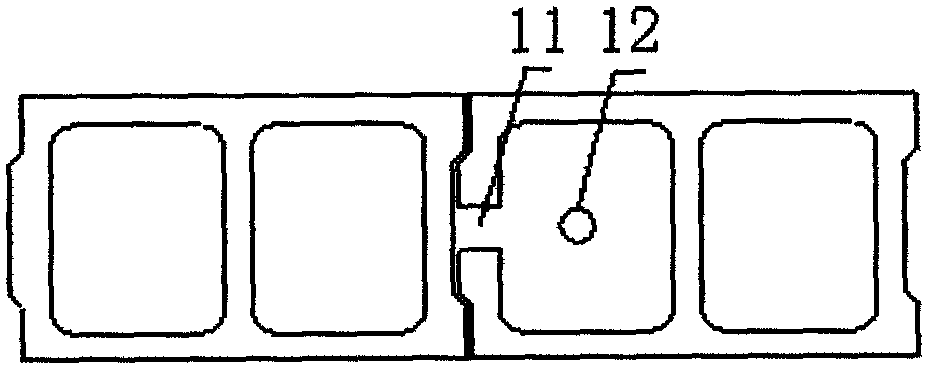

Free pre-burying construction method of wall pipeline

A technology for pipelines and walls, which is applied in the field of pre-embedded construction of pipelines in wall masonry, can solve the problems of easy cracking of walls and difficulty in ensuring the quality of masonry construction, and achieve the goals of not being easy to crack, reducing cost, and ensuring construction quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

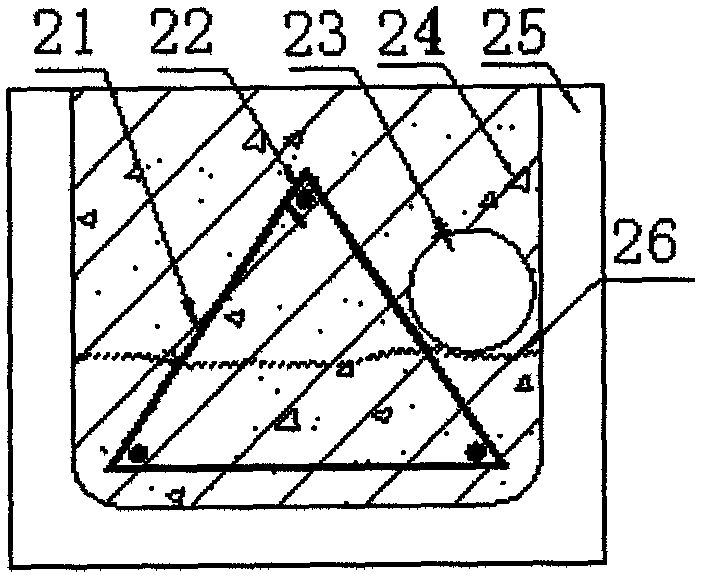

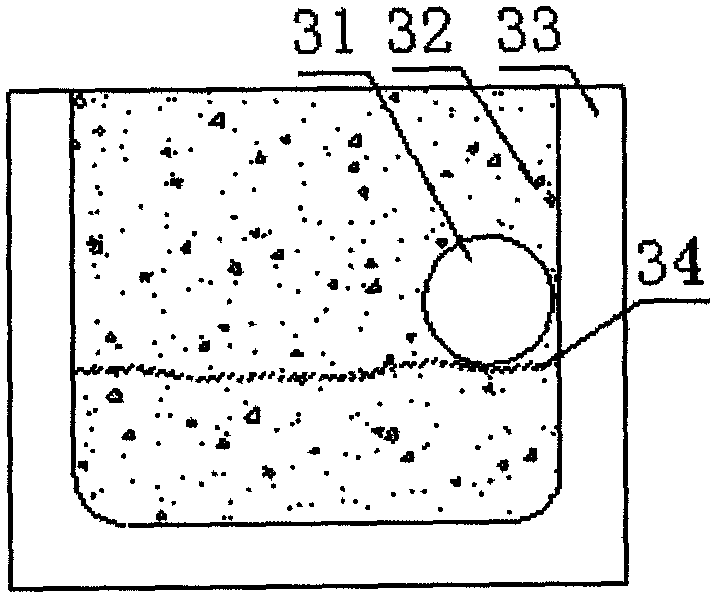

[0017] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

[0018] 1) The main content of the positioning and setting-out steps are:

[0019] Determine the position and number of reserved holes according to the design drawings, so as to determine the direction of the embedded pipeline, and then measure and set out the embedded pipeline and reserved holes in sections. The specific process consists of the following three procedures

[0020] 1.1 Joint review of drawings, before the start of construction, compare and review civil engineering drawings, installation and decoration drawings, conduct a detailed review of embedded pipelines and pre-embedded holes reflected in the drawings, and determine the location, size, specification, and quantity of embedded pipelines and res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com