Bare conductor electrified binding winder

A bare wire and wire winder technology, which is applied in the field of bare wire live bonding wire winder, can solve problems such as easy to pierce insulating gloves, vicious electric shock accidents, and low bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

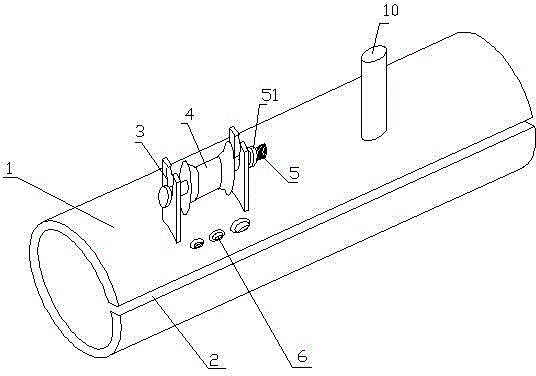

[0016] as attached figure 1 As shown, the bare wire live-bonding winding device includes a tube body 1, on which an axial wire inlet 2 is arranged, and the wire inlet 2 extends from one end of the tube body 1 to the other end.

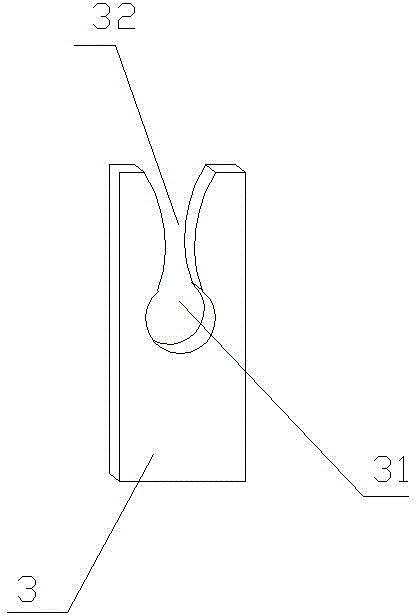

[0017] as attached figure 1 As shown, a reel stand is provided on the outer wall of the pipe near the left end of the pipe body. The reel stand includes two vertical plates 3 perpendicular to the outer wall of the pipe body. A reel 4 is arranged between the two stand plates. The two ends of wheel 4 and the wire wheel shaft are supported on the vertical plate, and the wire wheel 4 can rotate freely around the wire wheel shaft 5, and the tube body wall at the bottom of the wire wheel is provided with a binding wire entering hole 6.

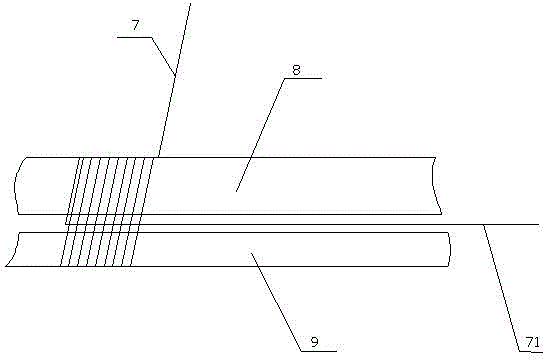

[0018] During use, the binding wire 7 is wound on the wire pulley 4, and the pipe body 1 is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com