A fry production line device

A production line and fried product technology, applied in the field of fried product production line devices, can solve problems such as unfavorable large-scale industrial production, increase employee work safety, affect processing efficiency, etc., and achieve the effects of convenient implementation, simple structure, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

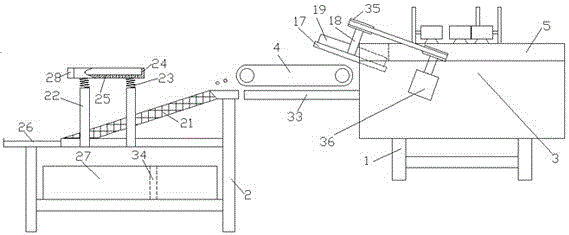

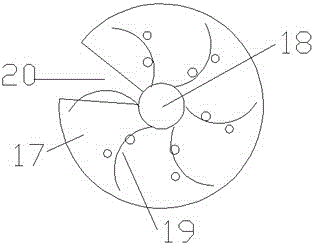

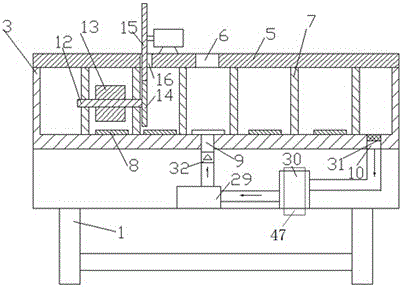

[0024] refer to Figure 1 to Figure 7 , the present invention relates to a fried product production line device, comprising a frying frame 1 and a feeding frame 2, one side of the frying frame is provided with an oil pan 3, and the other side of the frying frame is A conveying mesh belt 4 is provided, a pot cover 5 is provided on the oil pot, a feed inlet 6 is provided on the pot cover, a spiral partition with an outer end connected to the inner wall of the oil pot is provided in the oil pot 7. An electric heating element 8 is installed in the oil pan channel formed by the spiral partition, an oil inlet 9 is provided on the oil pan located in the center of the spiral partition, and an oil inlet 9 is provided on the oil pan located at the outer end of the spiral partition. There is an oil outlet 10. In order to realize the recycling of the oil body in the oil pan, the above-mentioned oil inlet is connected with the oil outlet pipeline of an oil delivery pump 29, and the oil out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com