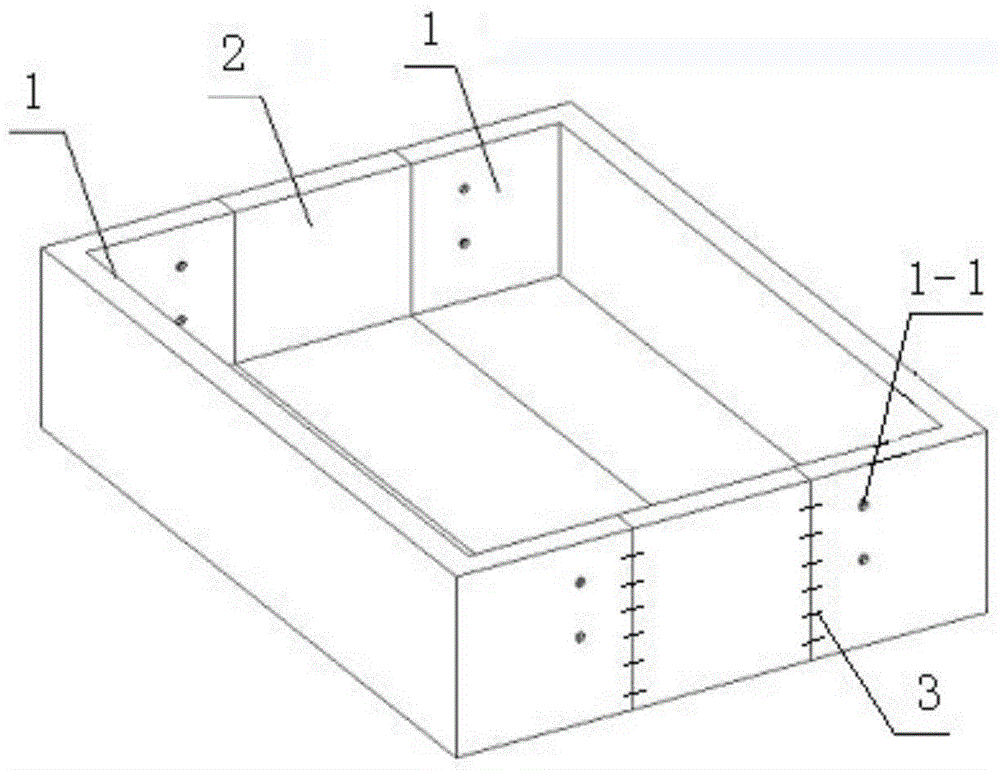

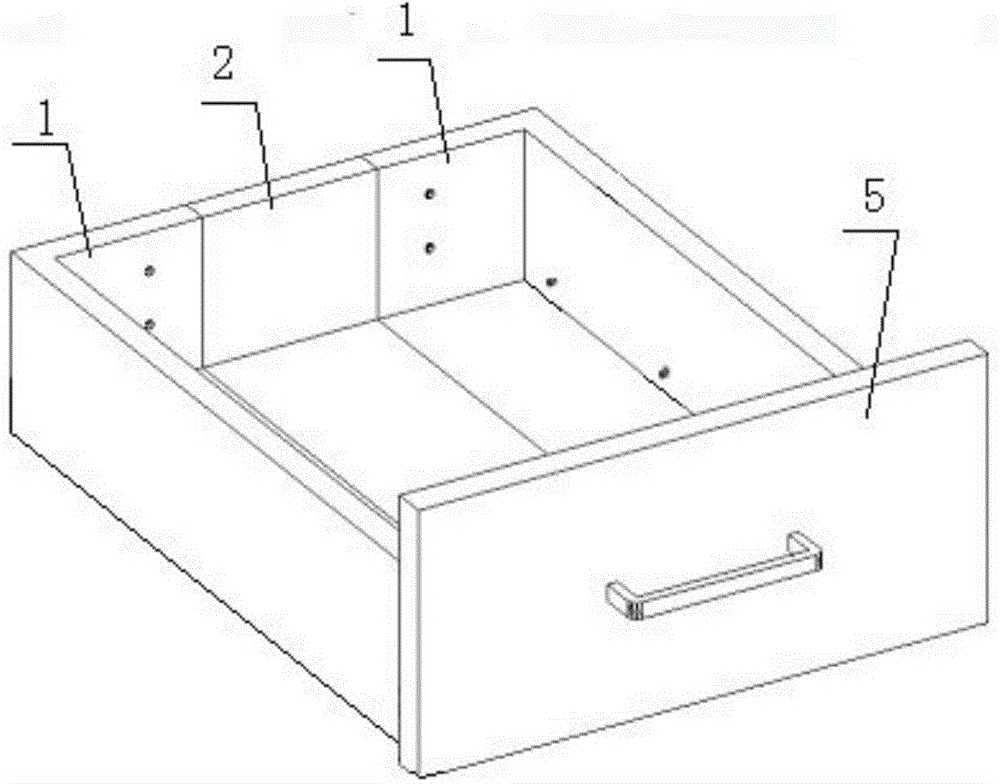

Box-type main body of drawer formed through jointing of members

A component and drawer technology, which is applied in the box-type main body field, can solve the problems of long working hours and complicated drawer processing process, and achieve high production efficiency, which is conducive to furniture standardization and improves production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

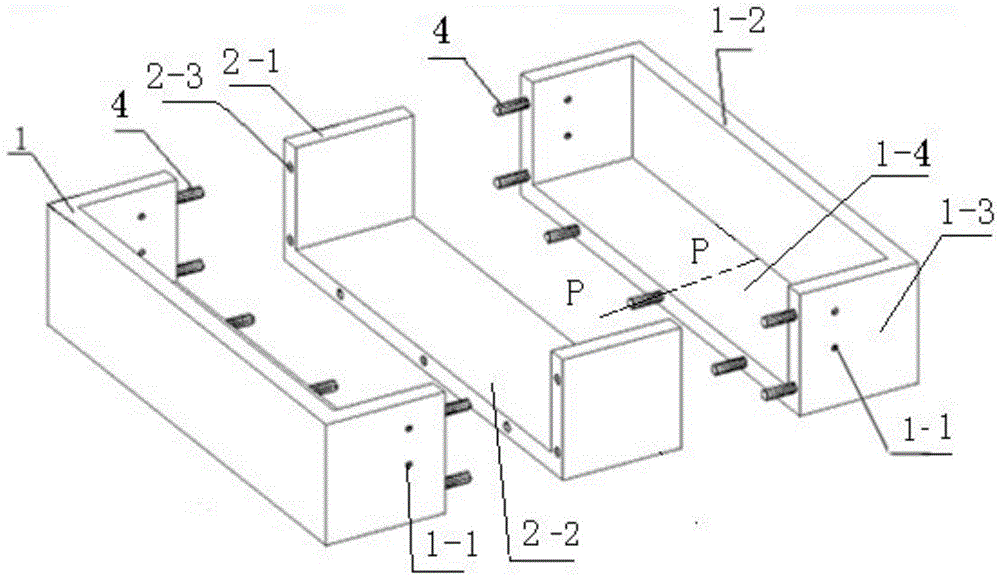

Method used

Image

Examples

Embodiment 3

[0029] Embodiment 3 is an application example of the box-type main body with the narrowest width of the present invention. Cooperating with Embodiments 1 and 2, it can meet the basic requirement of a set of furniture for drawer width and narrowness.

[0030] The first component 1 and the second component 2 of the above embodiments are respectively completed by injection molding and extrusion molding, and the wood-plastic composite materials, processing techniques and equipment used are all in the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com