Improved DMTO reactor

A reactor and improved technology, which is applied in the field of improved DMTO reactors, can solve the problems of increasing secondary reactions of olefins, bed fluctuations, back-mixing, etc., and achieve the reduction of catalyst concentration, reduction of secondary reactions, and reduction of catalyst amount Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

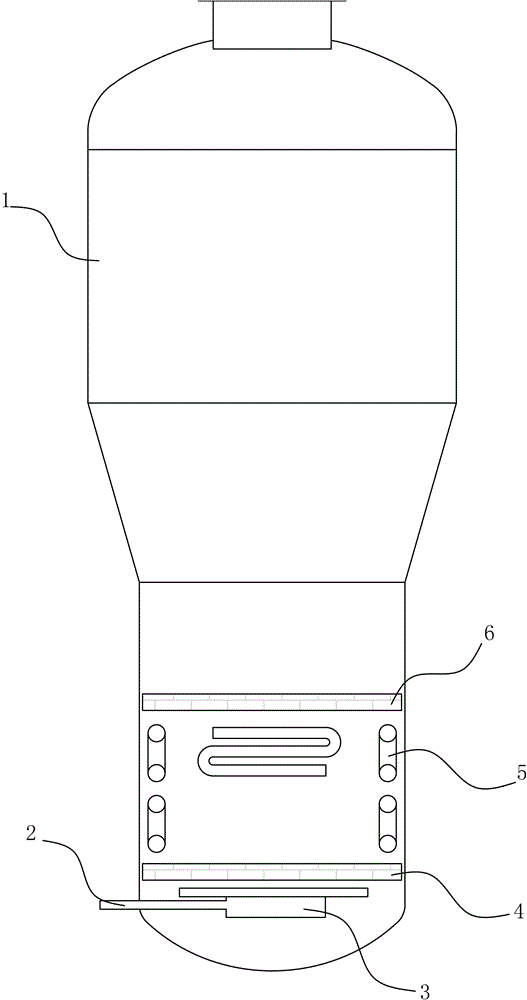

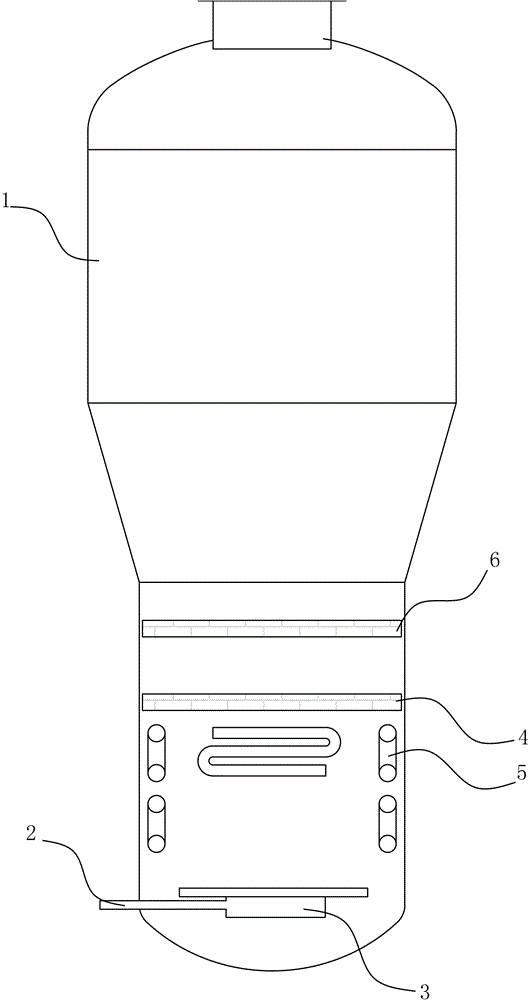

[0013] Figure II Shown is a second embodiment of the invention. The difference from the first embodiment is that in this embodiment, the two layers of grids are arranged on the upper part of the dense bed, and their heights are lower than the bed interface. This setting avoids interference with the heat collector in the dense-phase bed, and at the same time effectively reduces the size of the air bubbles reaching the bed interface, so that there is less catalyst entrained, reducing the pressure in the dilute-phase bed. The catalyst concentration is low, reducing the occurrence of secondary reactions; reducing the disturbance of the bed interface caused by bubble breakage, improving the stability of the bed and reducing the occurrence of back mixing. Through the above optimization, the yield of olefins is improved.

[0014] Compared with the prior art, the present invention has the following beneficial effects: the present invention arranges grids in the dense-phase bed area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com