High-precision sensor verifying apparatus

A technology for calibrating devices and sensors, which is applied to measuring devices, instruments, and measuring fluid pressure, etc., can solve problems such as small measuring range and narrow application range, and achieve the effect of large measuring range, wide application range and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

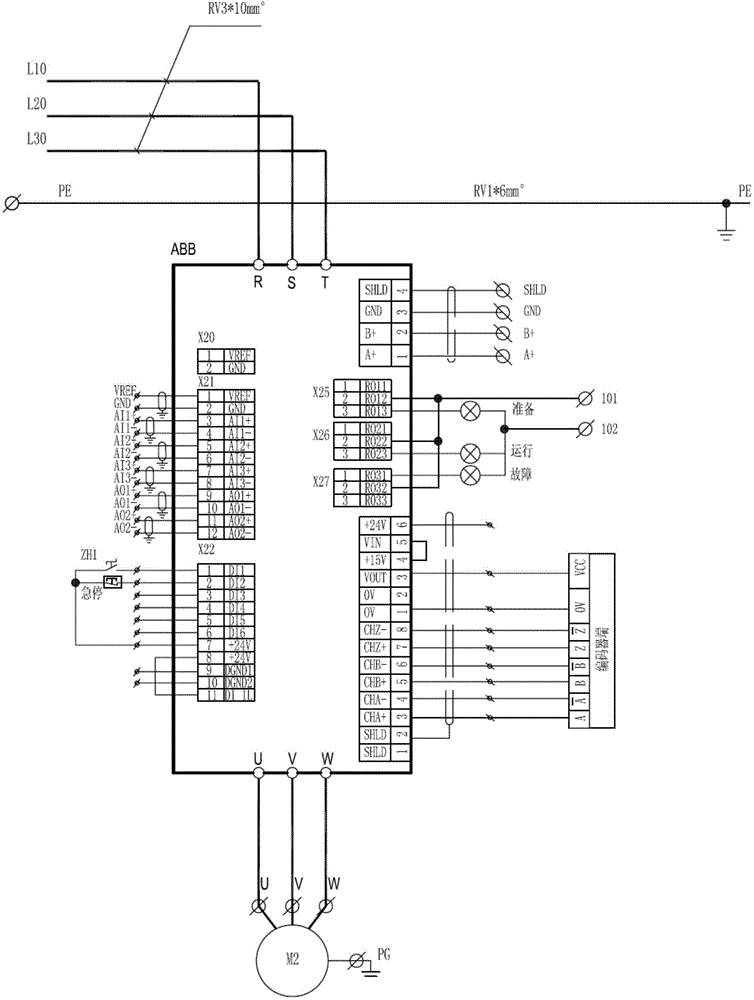

[0028] The high-precision sensor calibration device of the present invention includes a mechanical structure module and an electrical system module.

[0029] 1) Mechanical structure module:

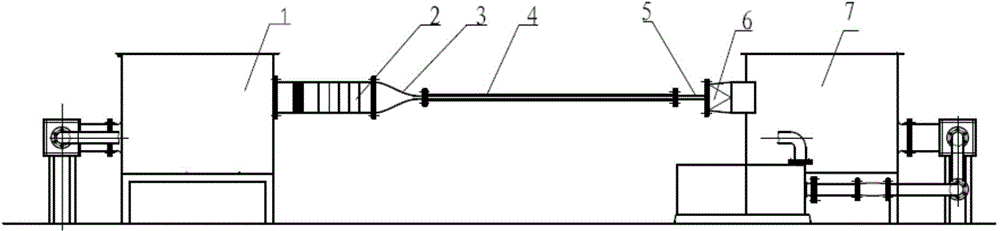

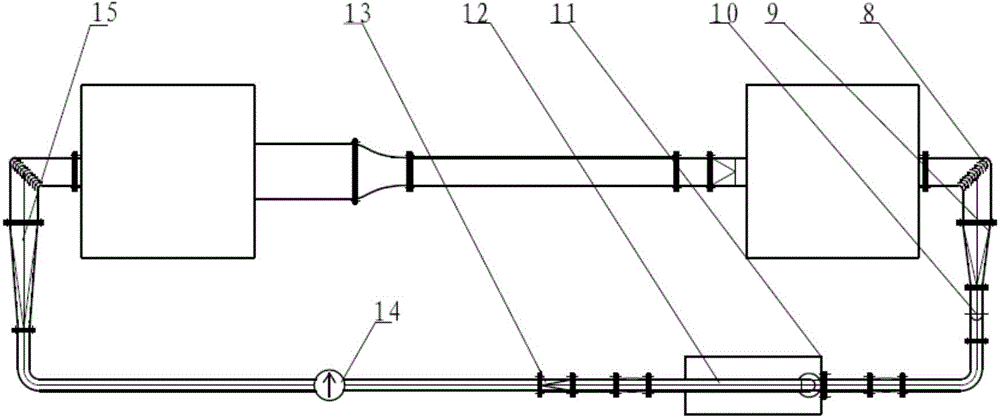

[0030] Such as figure 1 and figure 2 As shown, the mechanical structure module is a horizontally placed circulation pipeline structure, the medium in the circulation pipeline is water flow, and includes equipment for adjusting the fluid in the circulation pipeline to transform into a stable and developing turbulent flow and equipment for monitoring fluid flow parameters. Specifically, in figure 1 and figure 2 In the embodiment of the present invention, a water inlet box 1 and a water outlet box 7 are included, and the water inlet box 1 and the water outlet box 7 are connected by a test channel and a return channel.

[0031] The test channel can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com