Bridge influence line dynamic test method

A dynamic test, influence line technology, applied in the direction of elasticity test, machine/structural component test, measuring device, etc., can solve the problem of not getting the ideal influence line characteristic curve, deviation, the existence of amplitude or shape distortion of the influence line, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

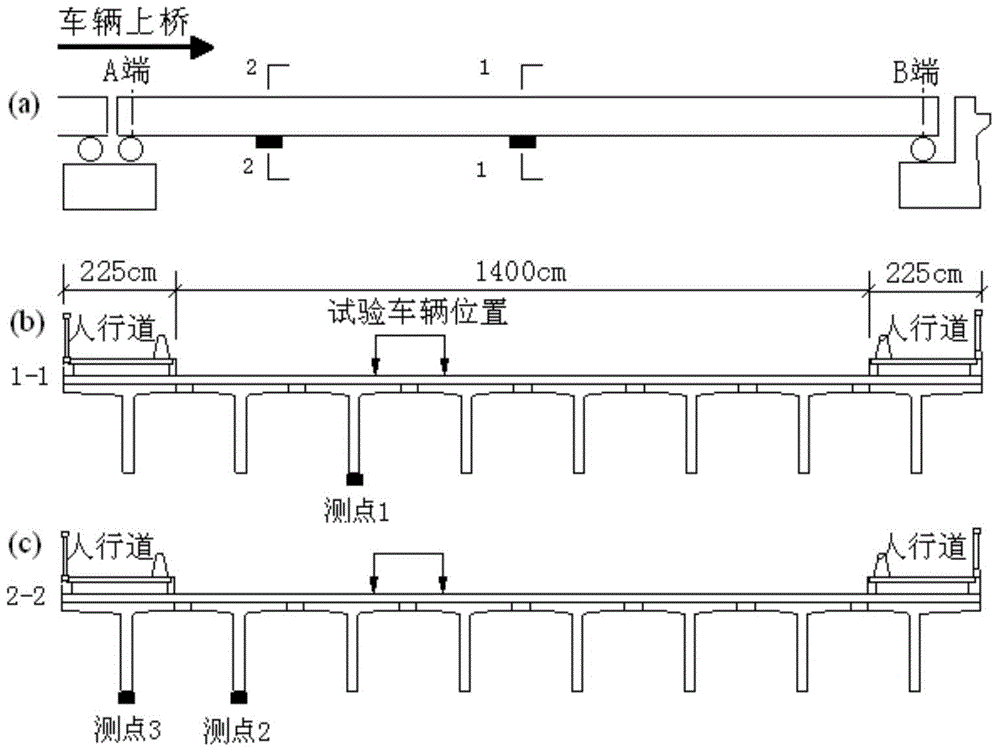

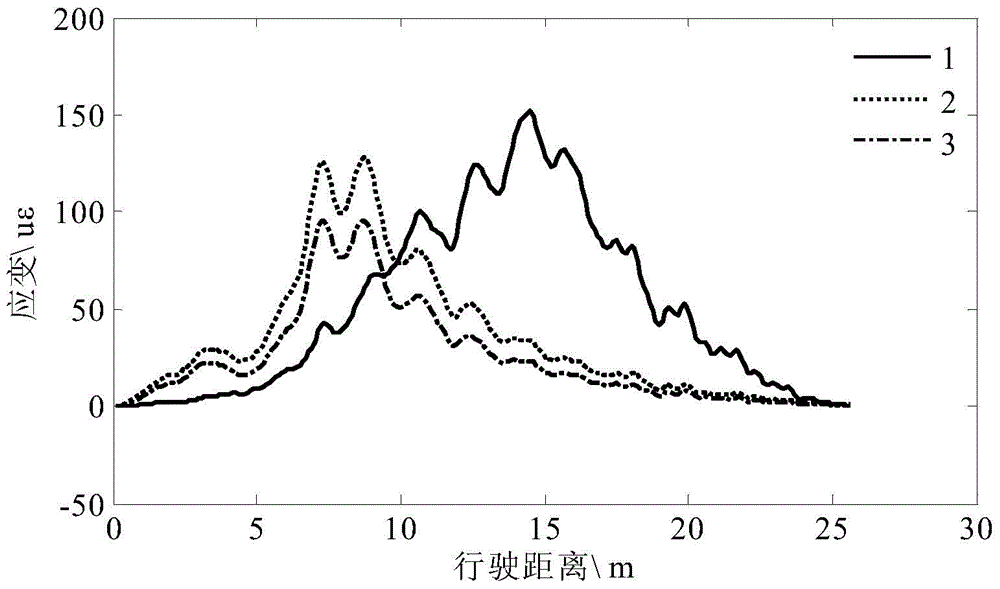

[0112] Taking a concrete simply supported T-beam bridge with a span of 20.0m as an example, the bridge strain influence line was tested on site and the auxiliary test showed that the vertical vibration frequency of the bridge was 3.06Hz. The direction and position of the vehicle crossing the bridge figure 1 (a), select section 1 at mid-span and section 2 at a distance of 3.1m from the end as the test section; there are 3 effective strain measuring points, and the measuring points are arranged as figure 1 (b), figure 1 As shown in (c), the 3rd beam from left to right at section 1 is measuring point 1, the 2nd beam from left to right at section 2 is measuring point 2, and the first from left to right at section 2 #Beam is measuring point 3. The section and measuring points are arranged as figure 1 Shown.

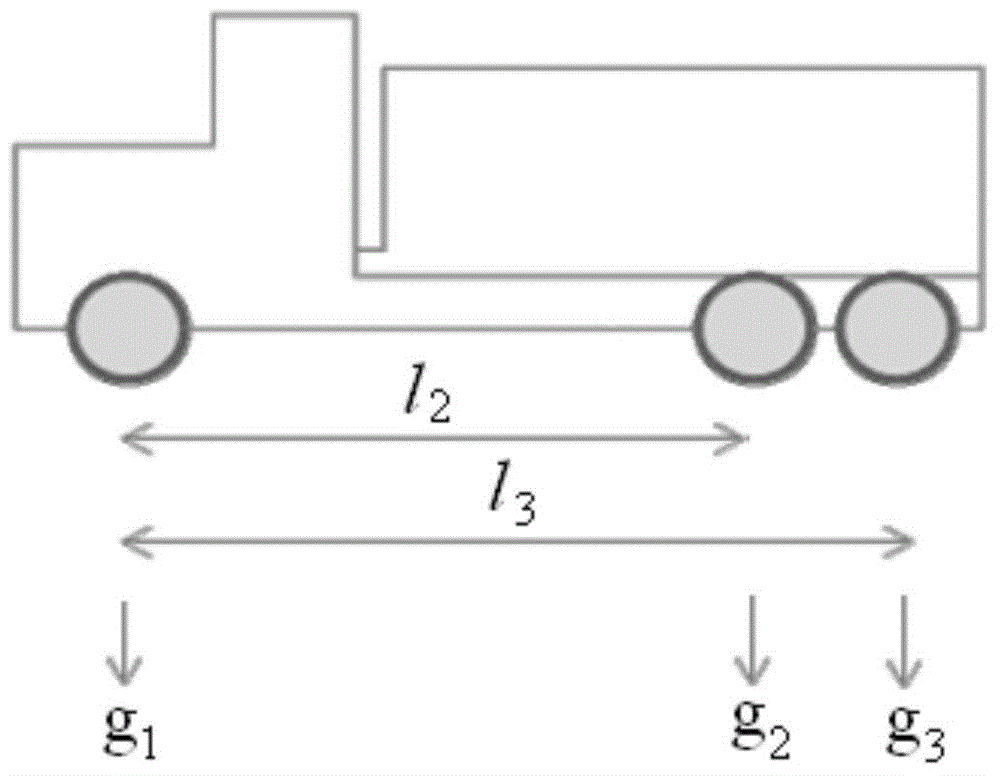

[0113] A three-axle vehicle is used as the test vehicle. The measured 1-2 wheelbase is 4.0m, the 2-3 wheelbase is 1.4m, and the measured three-axle weight is 8.94×10. 3 kg, 1...

Embodiment 2

[0121] From the perspective of model tests, the correct feasibility of the method for extracting the influence line of the bridge is verified and the advantages of similar methods are compared. The bridge model is a steel girder-slab bridge, which consists of two pieces of 100mm×68mm×4.5mm "I" steel beams and 4mm thick steel bridge deck welded together, with a length of 5.6m and a width of 0.56m. The vehicle model is a mass-adjustable 2-axle vehicle (wheelbase 0.365m). Its lateral position is constrained by the bridge deck rails. During the test, it is pulled by an electric motor and its speed is controlled. Appropriate approach bridges are installed in front of and behind the bridge to simulate the vehicle’s upper bridge and For bridge exit behavior, the strain measurement points are selected at the bottom of one side of the steel beam and arranged along the longitudinal direction. The model and measurement points are arranged as Image 6 , Measuring point 1 is arranged at 1 / 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com