Aluminium-magnesium alloy housing-closed bus duct

A technology of aluminum-magnesium alloy and busway, which is applied in the direction of fully enclosed busbar devices, can solve the problems of inconvenient installation, construction and connection of multi-channel cables, and achieve the effects of reducing installation costs, saving space, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

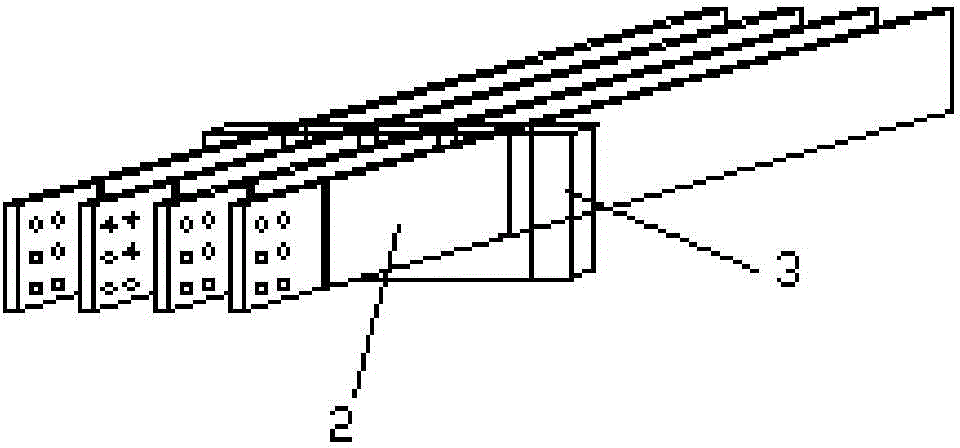

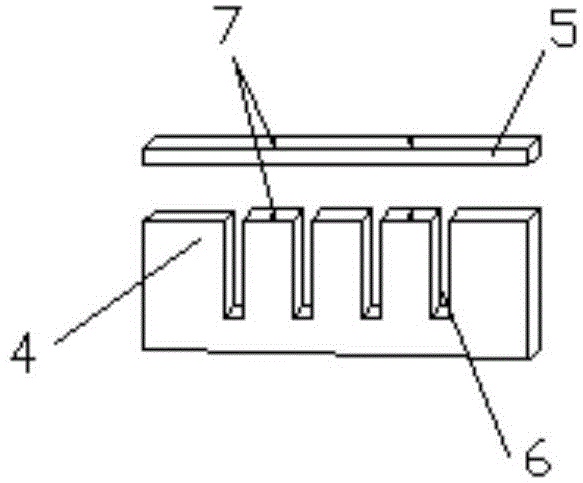

[0018] The aluminum-magnesium alloy shell of the present invention closes the bus duct, including a shell 1 made of aluminum-magnesium alloy and a plurality of copper bars 2 installed in the shell 1, the direction of the copper bars 2 is consistent with the length direction of the shell 1, The copper bars 2 are arranged parallel to each other and at intervals, and the outer walls of the copper bars 2 are all cast with epoxy resin insulating layers. The shell 1 and the copper bar 2 are connected through an insulating member 3, and the insulating member 3 is provided with grooves for engaging the copper bar 2, and the grooves are separated from each other, and the number of the grooves is the same as The number of copper bars 2 is consistent. The side of the housing 1 is a tile structure. The number of copper bars 2 is four.

[0019] The bus duct group formed by connecting the closed bus ducts of the above-mentioned aluminum-magnesium alloy shells, the adjacent closed bus duct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com