Device for functional continuous quick freezing

A quick-freezing device and functional technology, which is applied in household refrigeration devices, cooling fluid circulation devices, lighting and heating equipment, etc., can solve problems such as uneven freezing and quality deterioration, and achieve the effect of reducing quality deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be described in detail based on the illustrated embodiment.

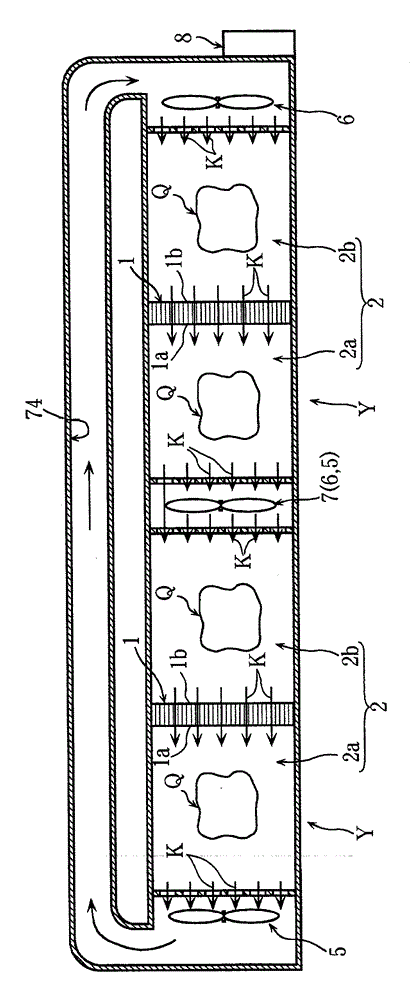

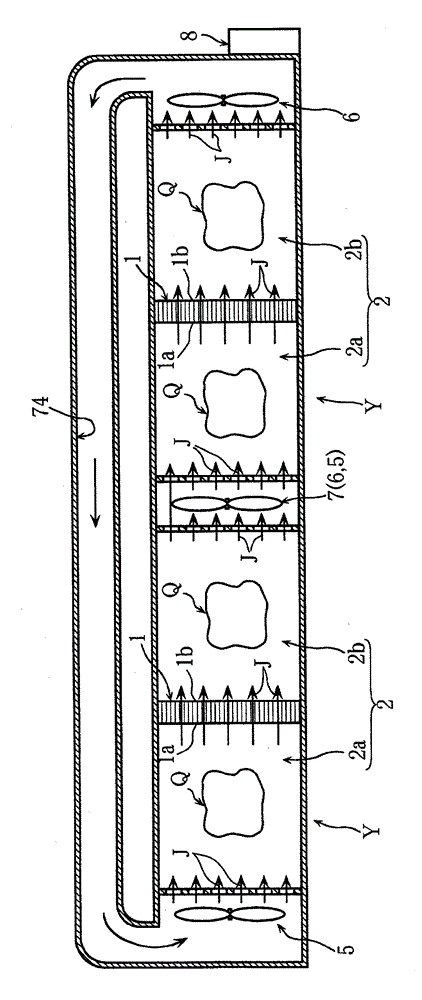

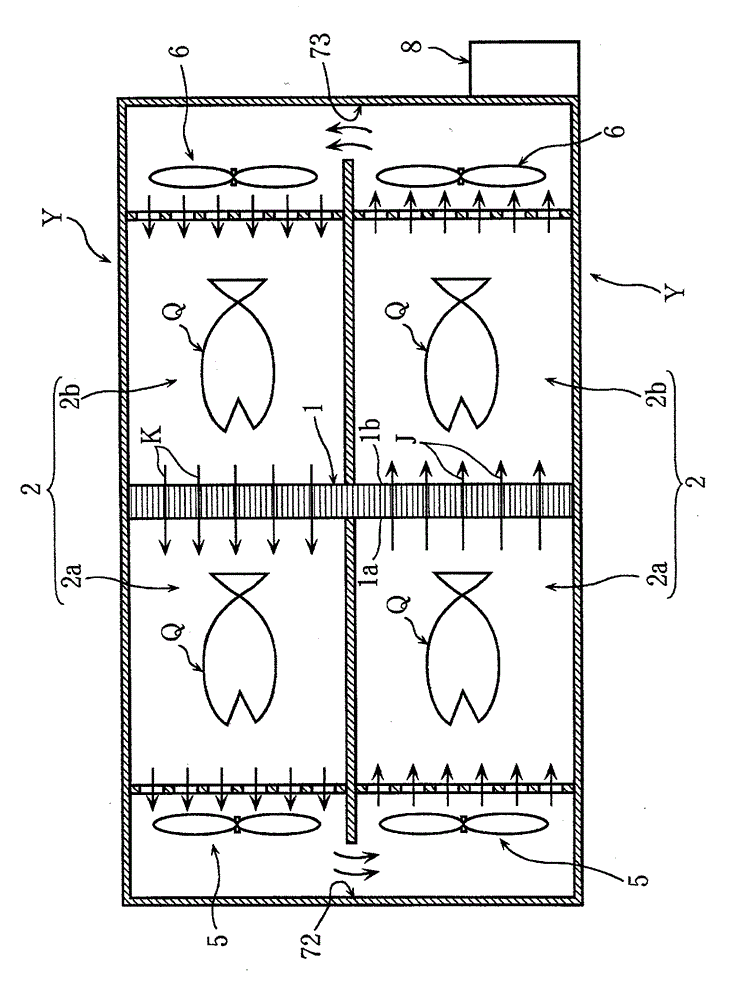

[0031] The functional continuous quick-freezing device involved in the present invention is such as figure 1 as well as figure 2 As shown, a freezer compartment 2 that accommodates a to-be-frozen object Q such as food and food, and a cooling heat exchanger (refrigerant evaporator) 1 arranged in the shape of a partition in the center of the freezer compartment 2 in the left-right direction are provided.

[0032] The freezer compartment 2 is divided into two by the cooling heat exchanger 1 (hereinafter also referred to as the cooler 1 ) into the first freezer compartment 2a and the second freezer compartment 2b.

[0033] The cooler 1 cools the surrounding air to generate cold air, and a cooling medium such as refrigerant gas flows inside.

[0034] Moreover, it is a shape which can flow air (cold air) from the side of the one surface 1a of the cooler 1 to the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com