Method for manufacturing semiconductor epitaxial wafer, method for manufacturing semiconductor epitaxial wafer, and solid-state imaging device

A technology of solid-state imaging elements and epitaxial wafers, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., and can solve problems such as insufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] (Refer to the experimental example)

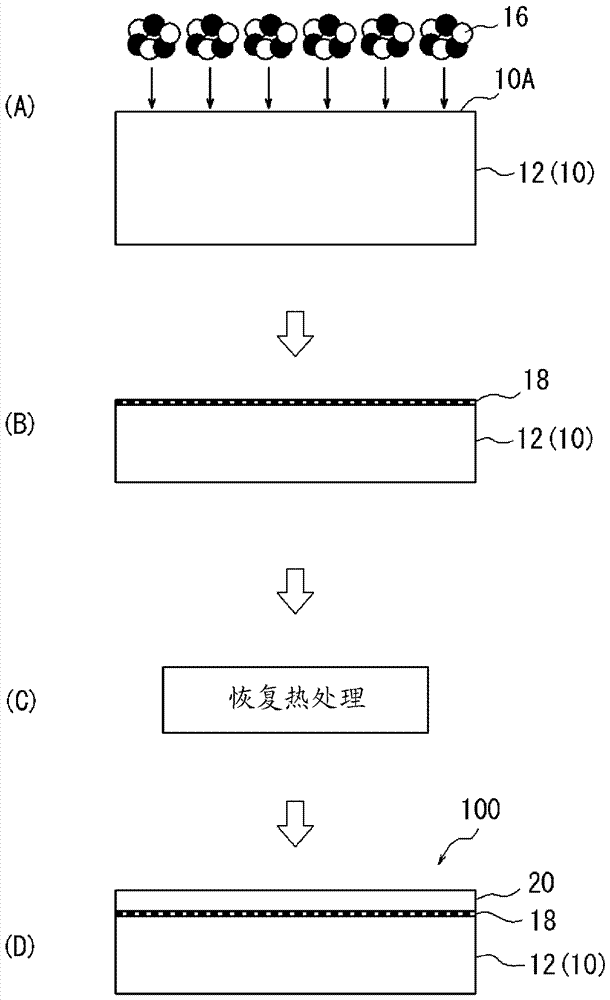

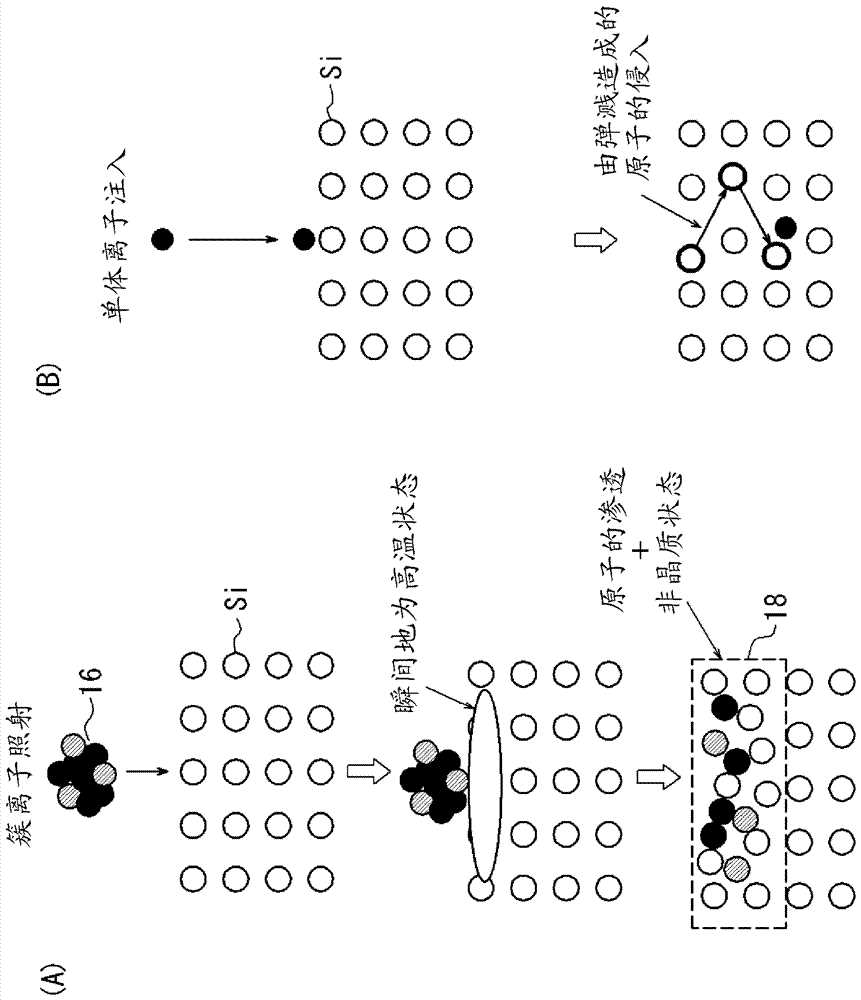

[0082] First, in order to clarify the difference between cluster ion irradiation and monomer ion implantation, the following experiments were performed.

reference example 1)

[0084] An n-type silicon wafer (diameter: 300 mm, thickness: 725 μm, doping: phosphorus, doping concentration: 4×10 14 atom / cm 3 ). Next, use a cluster ion generator (manufactured by Nisshin Ion Equipment Co., Ltd., model: CLARIS) to pass through biphenyl (C 14 h 14 ) to generate C 5 h 5 clusters, at a dose of 1.2 x 10 14 Cluster / cm 2 (Carbon dosage 6.0 x 10 14 atom / cm 2 ), the silicon wafer was irradiated under the irradiation conditions of 14.8keV / atom per carbon atom.

reference example 2)

[0086] For the same silicon wafer as in Reference Example 1, instead of cluster ion irradiation, CO 2 As a material gas, carbon monomer ions are generated, and the dose is set to 1.2×10 14 atom / cm 2 The silicon wafer was irradiated under the same conditions as in Reference Example 1 except for the conditions of an accelerating voltage of 300 keV / atom.

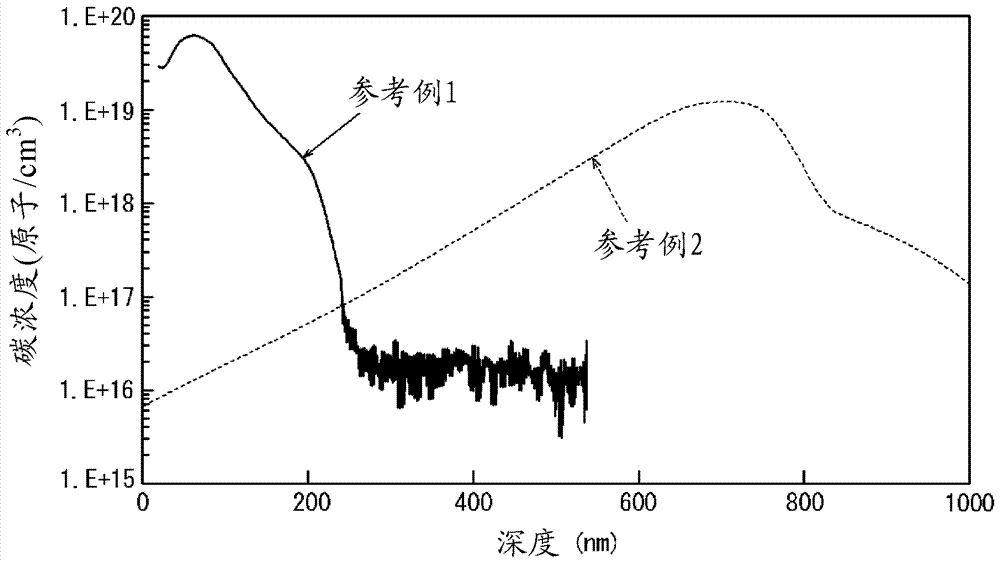

[0087] (SIMS measurement result)

[0088] The samples prepared in the above reference examples 1 and 2 were measured by SIMS to obtain Figure 4 Concentration profiles of carbon are shown. In addition, the depth of the horizontal axis is zero from the surface of the silicon wafer. if according to the Figure 4 As is apparent, in Reference Example 1 in which cluster ion irradiation was performed, the carbon concentration distribution was sharp, whereas in Reference Example 2 in which monomer ion implantation was performed, the carbon concentration distribution was broad. In addition, compared with Reference Example 2, in R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com