Extrusion mold for soft copper bar

A technology of extrusion dies and soft copper bars, applied in the direction of metal extrusion dies, etc., can solve the problems of length limitation, many processes, unfavorable processing, etc., and achieve the effects of guaranteed quality, soft force, and prolonging the molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

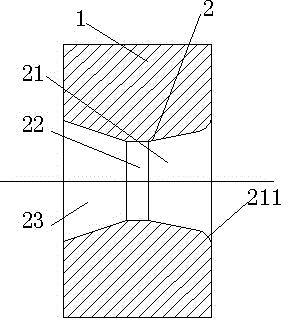

[0016] The present invention includes a mold body 1, and the mold body 1 is provided with a molding cavity 2, and the molding cavity 2 includes an incoming line cavity 21, a fixed diameter cavity 22, and an outgoing line cavity 23, which are sequentially connected front and back. The axes of the radial cavity 22 and the outlet cavity 23 are on the same straight line;

[0017] Along the wire outlet direction, the wire inlet chamber 21 is set with a narrow mouth, the wire outlet chamber 23 is set with a flared mouth, and the sizing chamber 22 is set with a flat mouth.

[0018] The taper of the inlet cavity 21 is 8-12°, and the taper of the outlet cavity is 13-17°.

[0019] The taper of the inlet cavity 21 is 10°, and the taper of the outlet cavity is 15°.

[0020] The wire inlet of the wire inlet cavity 21 is provided with a guide port 211 with a smooth transition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com