Buoyancy ball ejection device for underwater carrier

A technology of underwater vehicles and ejection devices, applied in transportation and packaging, underwater operation equipment, ships, etc., can solve problems affecting performance, loss, impact of vehicles, etc., and achieve the goal of improving use efficiency and reducing sealing requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

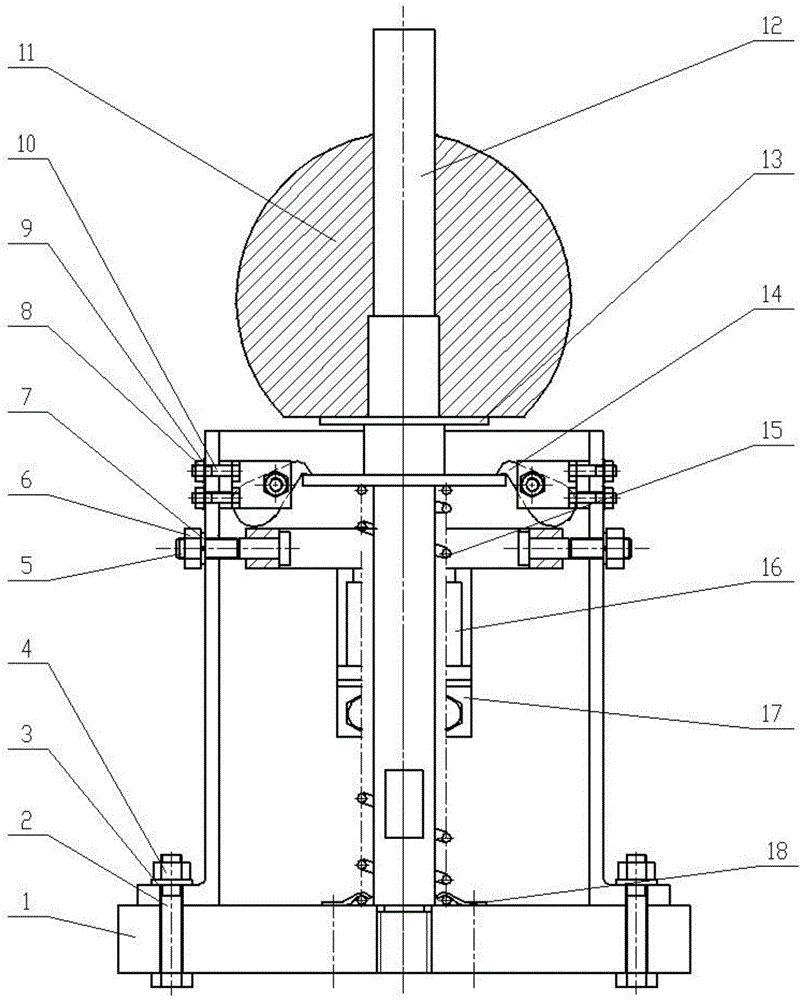

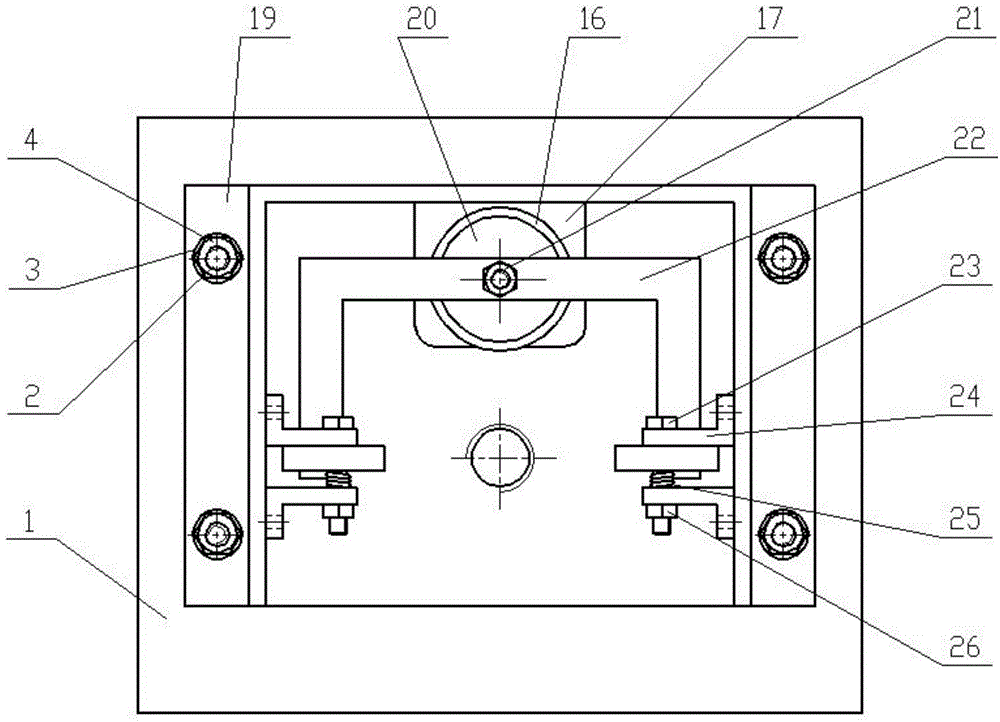

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0018] combine Figure 1~5 , the present invention mainly is made up of buoyancy ball positioning part, lever conversion part, buoyancy ball release part. The buoyancy ball spheroid 11 is installed on the spheroid support 13, and through hole is arranged in the middle of the spheroid support 13, is enclosed within on the guide bar 12. The lower end of the guide rod is threaded, and is fitted with the threaded hole of the bottom bracket 1. The spring 15 is placed along the guide rod 12, and its bottom end is fixed on the bottom bracket 1 by two spring pressing plates 18. The vertical plate bracket 19 is installed on the bottom bracket 1 through bolts 2, gaskets 3 and nuts 4, with a square hole in the middle, and two eagle hook brackets 24 are installed on both sides through nuts 8, gaskets 9 and bolts 10 respectively. , and there is a certain space in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com