Onsite electrical detection method for double load capacity of friction type lifting machine system

An electrical detection and elevator technology, applied in elevators, transportation and packaging, etc., can solve the problem of inability to detect and calculate the load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

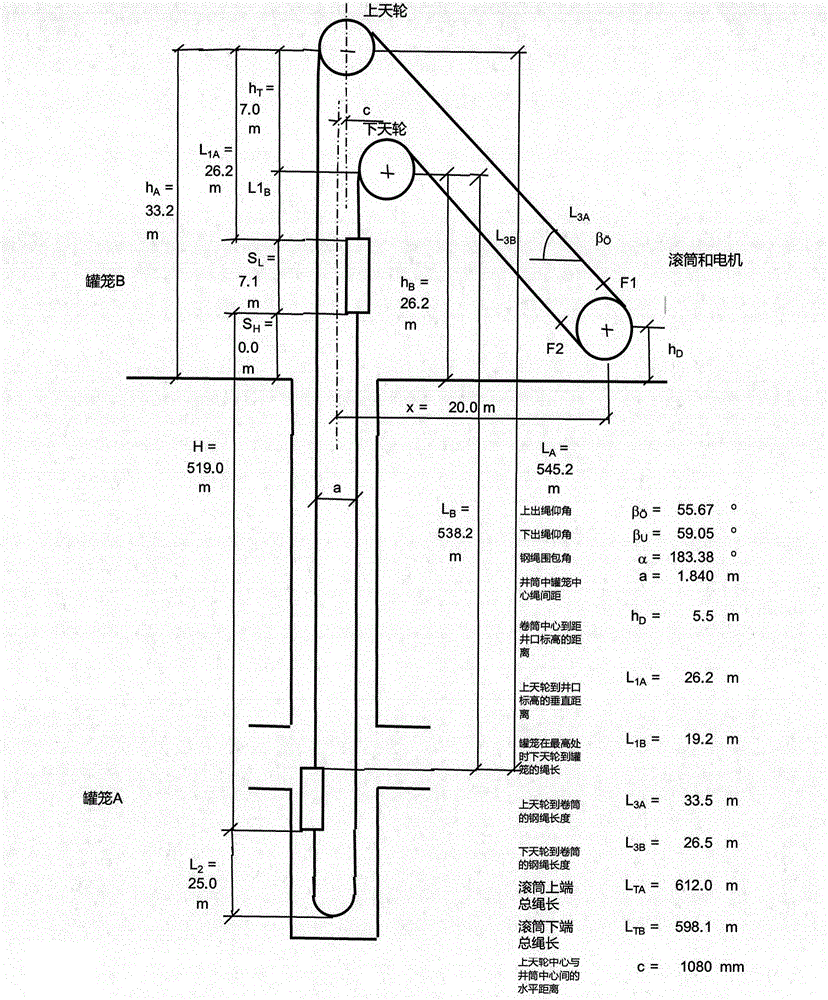

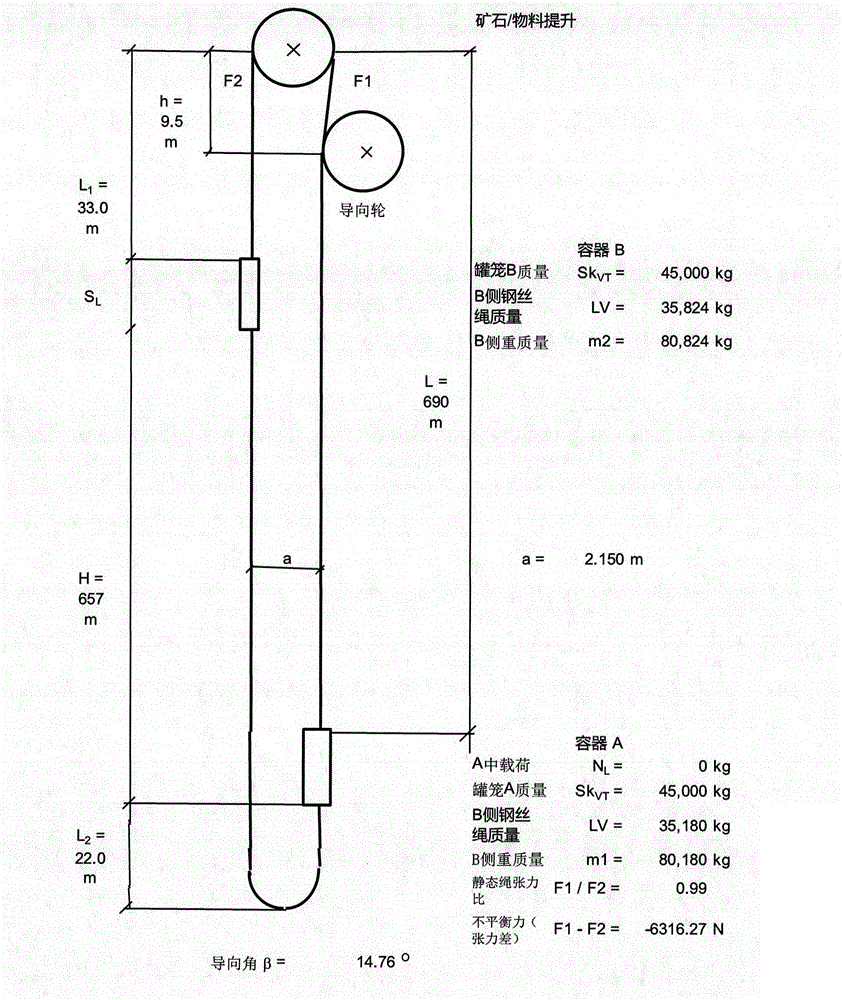

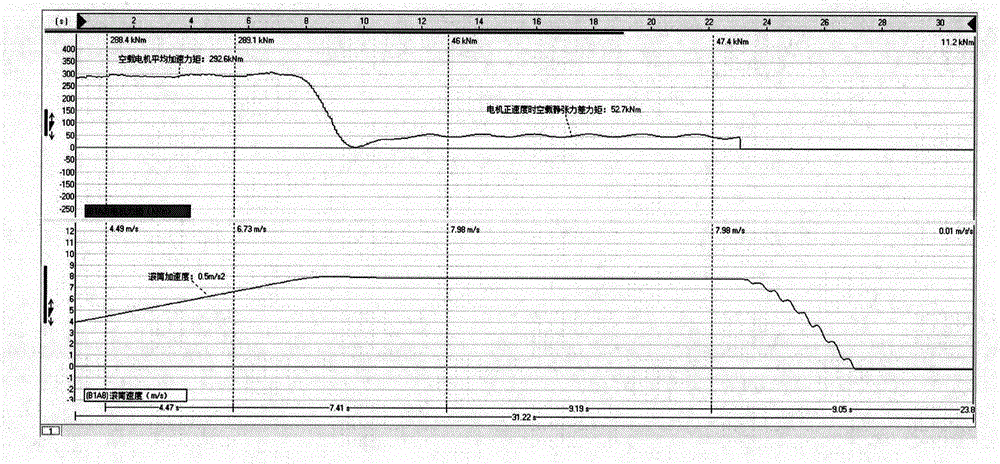

[0005] The present invention provides an automatic control system and an electric transmission system using a friction hoist. Through precise control, the hoist operates under a specific working condition, records the motor torque and the speed of the drum, and calculates the double cage or double skip. respective loads. It is characterized in that: firstly, after the hoist is hung with a rope, it is empty-loaded, the speed curve is precisely controlled, and the speed is uniformly accelerated to a stable hoisting speed, and it runs back and forth in the wellbore, recording the motor torque and the speed of the drum, and obtains the motor output when the hoist is running at forward and reverse speeds. Two different static tension differential moments and hoist system mass (including the displacement mass of motor, drum, sky wheel or guide wheel, cage or skip and the quality of the head and tail rope); after that, the hoisting system is loaded, through precise Control the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com