Tailing piling and storing system and method for reducing environment pollution

A technology of tailings and ore pipes, which is applied in the tailings stockpiling of mine tailings in mineral processing plants and the tailings stockpiling system to eliminate the hidden dangers of tailings dam instability or dam collapse, reduce the risk of instability or dam collapse, The effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples.

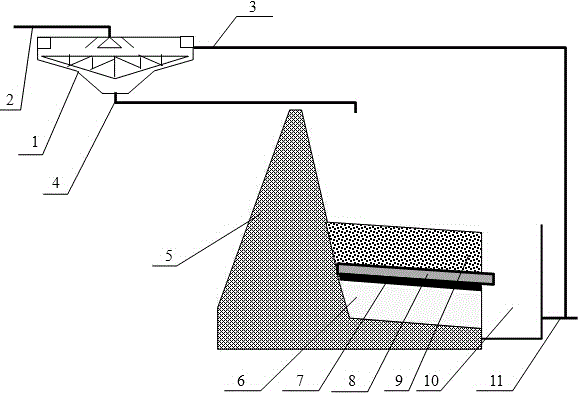

[0023] Such as figure 1 As shown, a tailings stockpiling system for reducing environmental pollution includes a tailings thickening pool 1, a concentrated tailings conveying pipeline and a tailings stockpiling site 5;

[0024] Concentrated tailings conveying pipeline includes ore feeding pipe 2, overflow ore outlet pipe 3, and bottom outflow ore pipe 4; the ore feeding pipe 2 of the tailings thickening tank 1 is connected with the tailings discharge pipe of the mine concentrator, and the tailings concentration The overflow outlet pipe 3 of the pool 1 is connected with the circulating water pipe 11, and the bottom outlet pipe 4 of the tailings thickening tank is connected with the tailings stockpile 5 through the conveying pipeline;

[0025] The bottom of the tailings stockpile 5 is provided with a waterproof compacted clay layer 6, and a geotechnical anti-seepage membrane 7 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com