A vertical keel installation structure with fast and precise adjustment function

A vertical keel and installation structure technology, which is applied to building components, building structures, walls, etc., can solve problems such as production safety, installation safety hazards, fatigue loosening and sliding, curtain wall plate falling, etc., to reduce high-altitude operations Strength, exempt from welding operations, reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

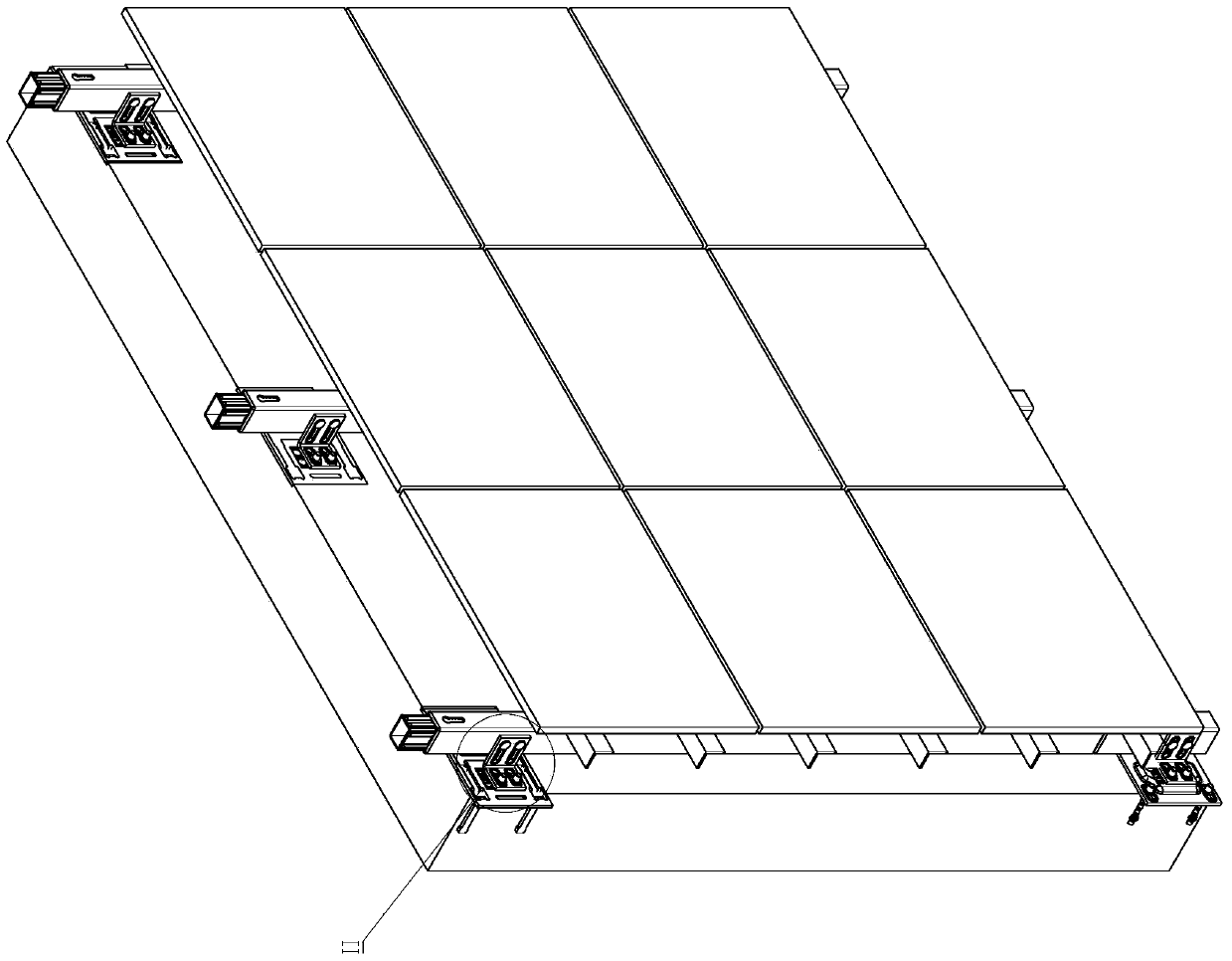

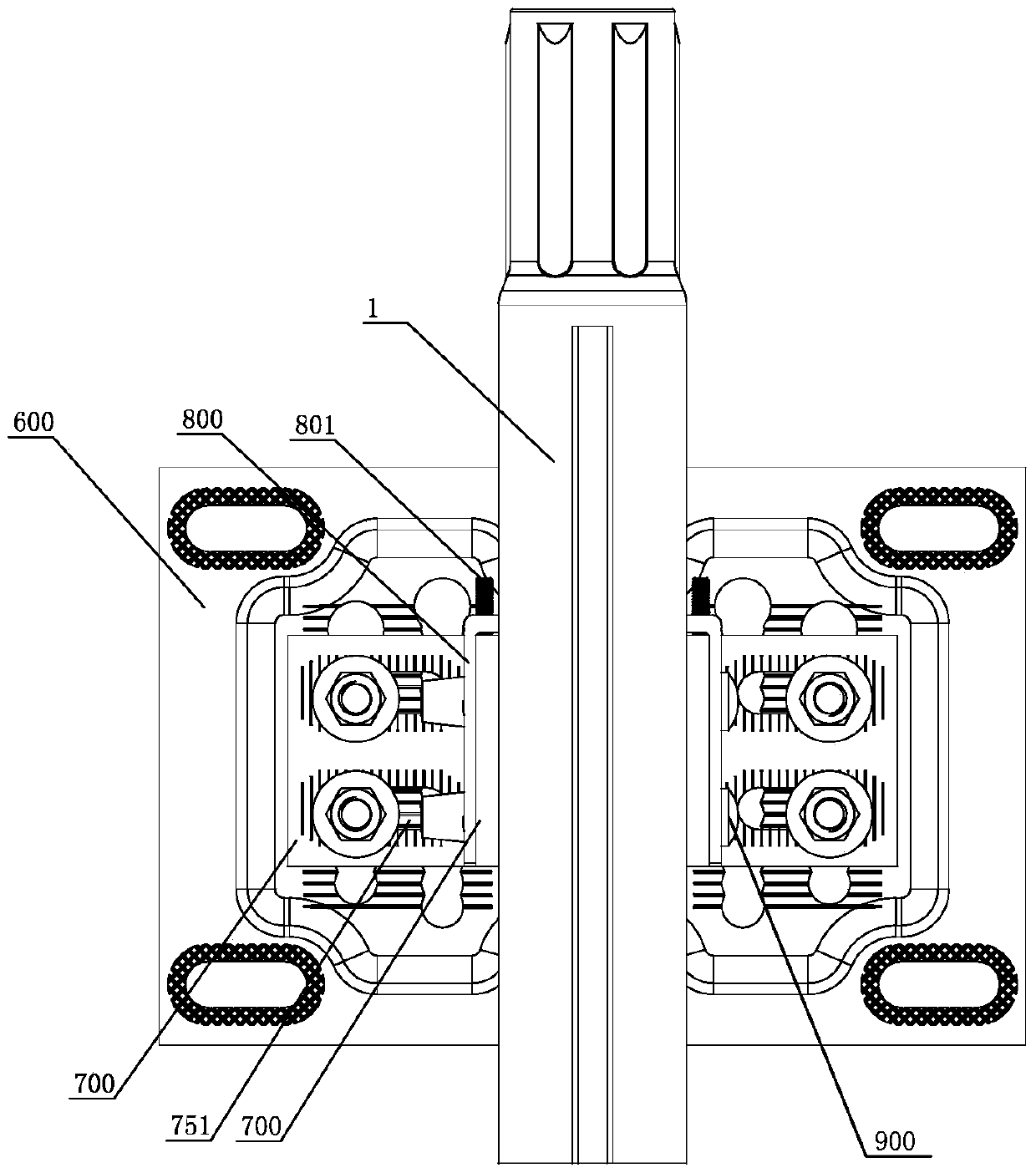

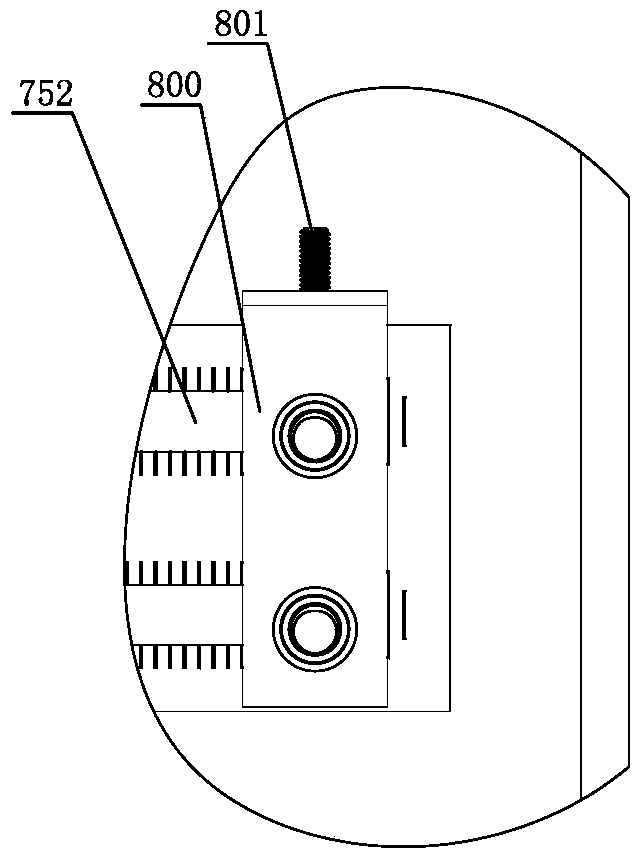

[0046] Refer to attached picture. The present invention is a vertical keel installation structure with fast and precise adjustment function. The vertical keel is provided with a bolt hole that transmits force to the secondary connector 700 of the pre-embedded anchor, so that the bolt rod passes through the bolt hole to bear force on the The secondary connector 700 on the side of the vertical keel, one side of the secondary connector 700 is connected to the vertical keel, and the other side is connected to the anchor plate 600, and the secondary connector 700 is matched with the vertical keel There is a vertical error adjustment gap between the connecting hole 752 and the bolt rod in the height direction, and there is a vertical error adjustment mechanism for the vertical keel between the vertical keel and the secondary connecting piece. The secondary connecting piece 700 adopts a corner code piece.

[0047] The bolt rod is a rod in the connecting piece, and the connecting pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com