Bored pile bit overshot and method

A technology of bored piles and overshots, which is applied in earthwork drilling, wellbore/well components, etc., which can solve problems such as easy scratches on the retaining wall, drill pipe breakage, and accidents in the hole, so as to shorten the processing time of drill drop and avoid The effect of damage and sticking, easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

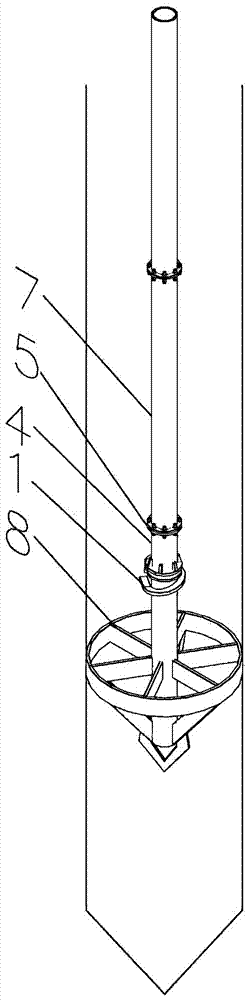

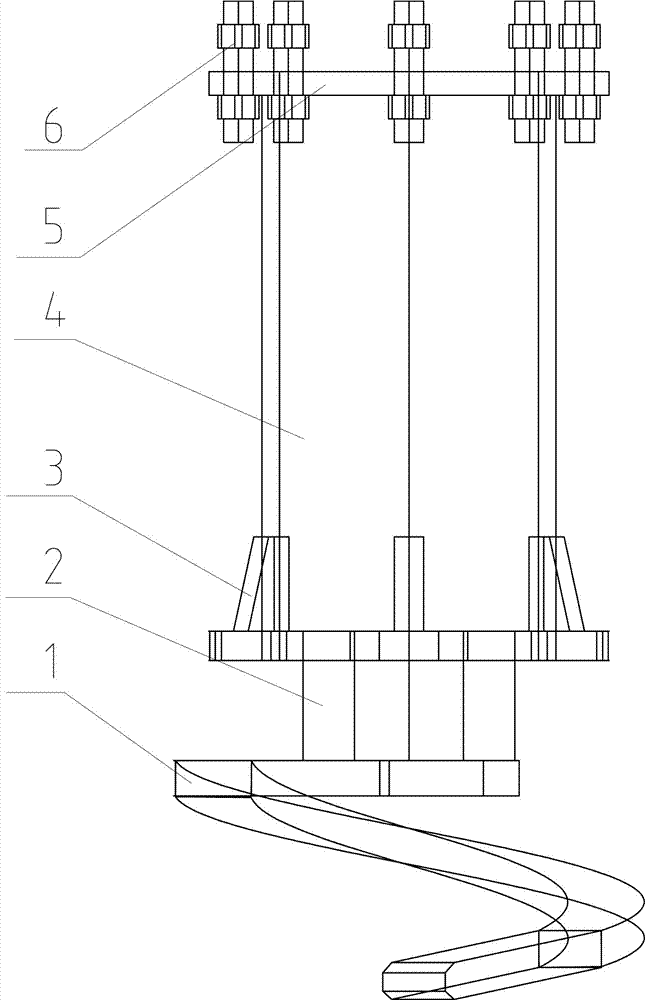

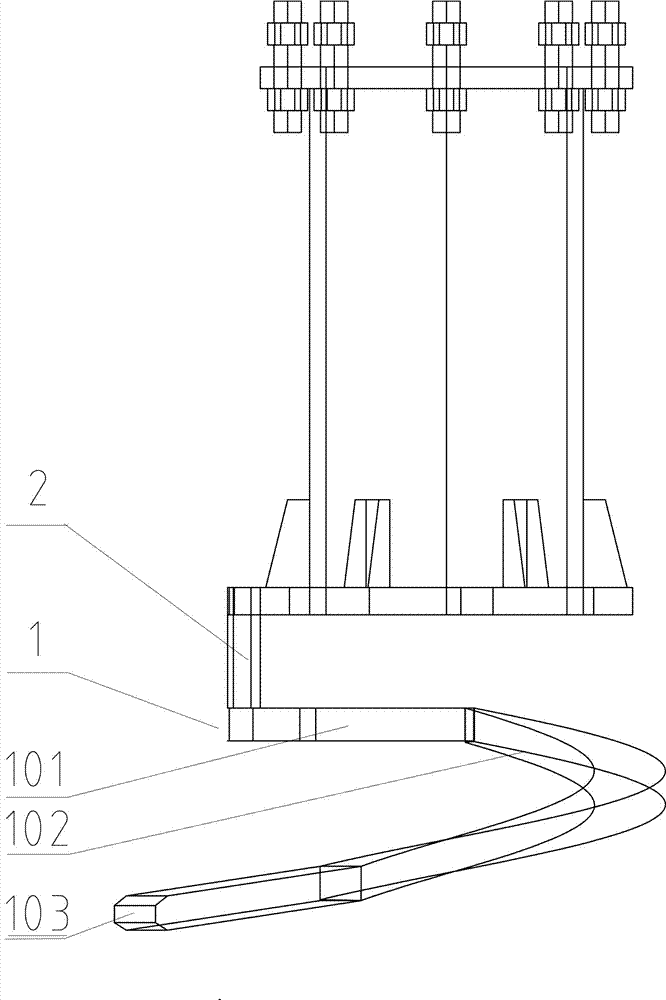

[0032] A kind of bored pile drill bit fisher, the end of connecting rod 4 is provided with helical guide device 1, and the length of connecting rod 4 is 60cm in this example, adopts the common drill pipe of circulating drilling rig to process and manufacture, and one end is provided with flange, through connecting The bolt is connected with the drill pipe 4 of the drilling rig. The other end is welded into a whole through a flange or a plate-like structure similar to a flange and a reinforcing rib 3 . The said helical guiding device 1 at least comprises an annular segment 101 , and a helical segment 102 is arranged at the end of the annular segment 101 . The screw guide adopts Q 235 The steel plate is cut and cold-bent.

[0033] At the end of the helical section 102 there is an outwardly stretched section 103 . Used for searching and touching broken drill bit or drill pipe.

[0034] The two ends of the connecting rod 4 are provided with a flange 5, the edge of the flange 5...

Embodiment 2

[0040] The pile foundation with a pile diameter of 1.5m jumps due to the exposure of large-sized floating pebbles during the drilling process, and the construction personnel neglected to install less connecting bolts, resulting in a sudden drill drop accident during the drilling process. Take this as an example Explain that the bored pile bit overshot is used to fish for the dropped drill bit.

[0041] In this example, the flange bolts at the connection position between the drill pipe and the drill bit were broken, the transmission failed, and the drill bit fell into the pile well.

[0042] Pull out the drill pipe in time after a drill drop accident, understand the detailed depth and location of the drill pipe fracture, analyze the cause of the drill drop, and formulate a drill bit salvage plan.

[0043] A method for salvaging a drill bit in a bored pile by using the above-mentioned drill bit catcher, comprising the following steps:

[0044] 1. Connect the connecting rod 4 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com