Furnace nozzle combustion device

A combustion device and burner nozzle technology, which is applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of insufficient combustion of combustible gas, and achieve the effects of preventing escape, good mixing effect, and improving mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

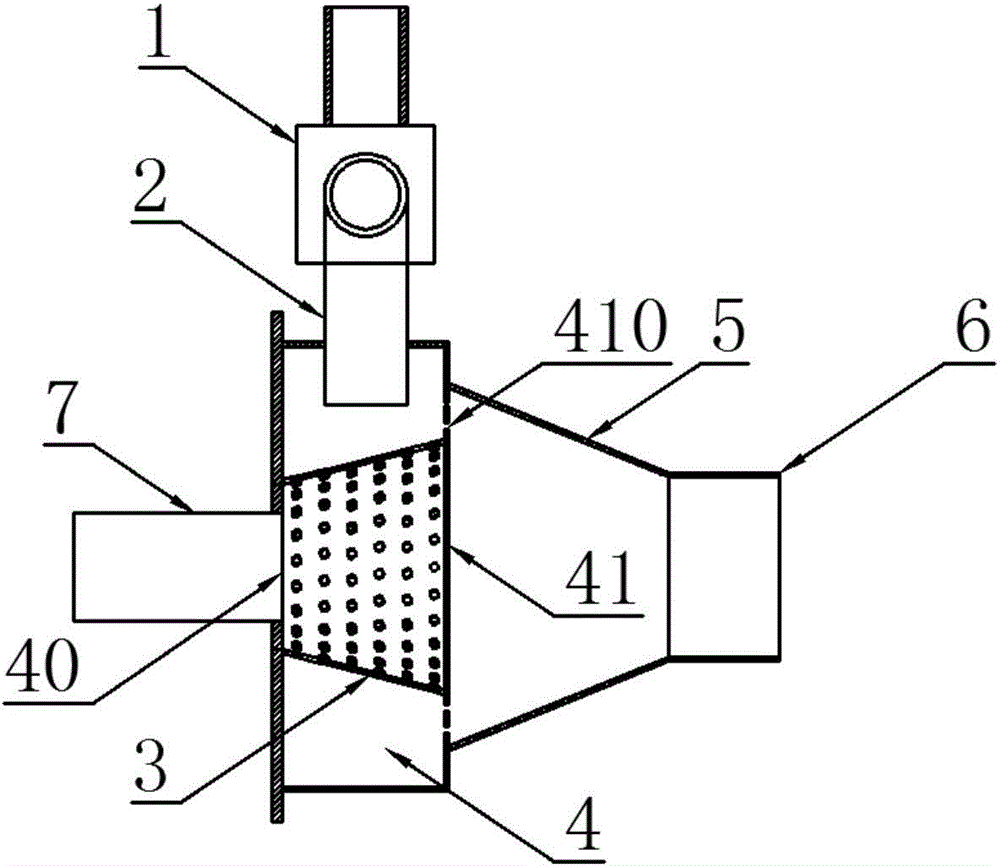

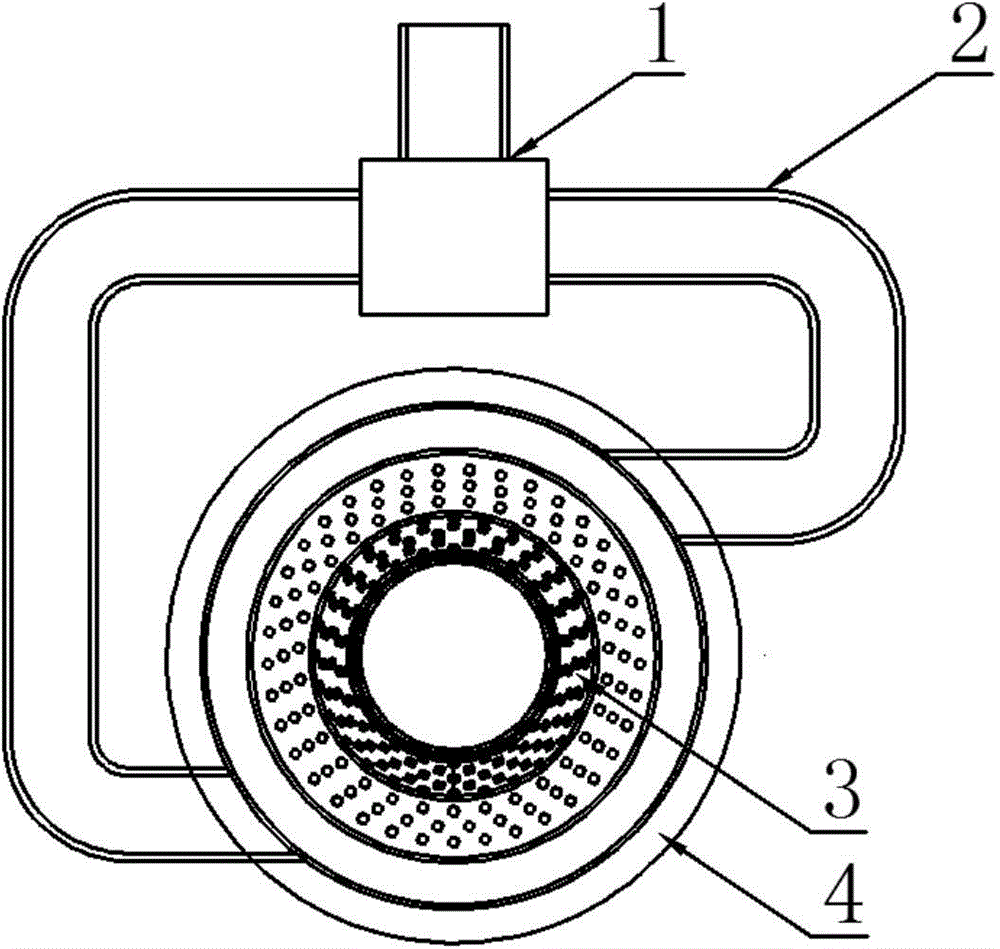

[0028] The structure of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0029] like figure 1 , 2 A burner nozzle combustion device shown includes an air chamber 4, a combustion chamber 5, and a burner 6 that are sealed and connected in sequence. Relatively speaking, the air chamber 4 is a large cylinder, and the burner 6 is a small cylinder. Cavity 5 is a conical cylinder, the large mouth of the conical cylinder faces the air chamber 4, and the small mouth of the conical cylinder faces the burner 6. This way can increase the density of the mixture at the burner 6, which is beneficial to ignite the mixture.

[0030] The air chamber 4 is provided with a mixing chamber 3, the mixing chamber 3 is a cone-shaped mesh cylinder, and the air chamber 4 is provided with a gas inlet 40, an oxygen inlet and a mixed gas outlet 41, which are respectively used for the entry of combustible gas, air and mixed gas. outflow. The mixed ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com